Maintenance

Downloadafreecopyoftheelectricalorhydraulicschematicbyvisitingwww.toro.com/en-gbandsearchingfor

yourmachinefromtheManualslinkonthehomepage.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

MaintenanceSafety

•Beforeyouleavetheoperator’sposition,dothe

following:

–Parkthemachineonalevelsurface.

–Disengagethecuttingunit(s)andlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

–Waitforallmovementtostop.

•Allowmachinecomponentstocoolbefore

performingmaintenance.

•Ifpossible,donotperformmaintenancewhilethe

engineisrunning.Keepawayfrommovingparts.

•Supportthemachinewithjackstandswhenever

youworkunderthemachine.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Keepallpartsofthemachineingoodworking

conditionandallhardwaretightened.

•Replaceallwornordamageddecals.

•Toensuresafe,optimalperformanceofthe

machine,useonlygenuineT ororeplacement

parts.Replacementpartsmadebyother

manufacturerscouldbedangerous,andsuchuse

couldvoidtheproductwarranty.

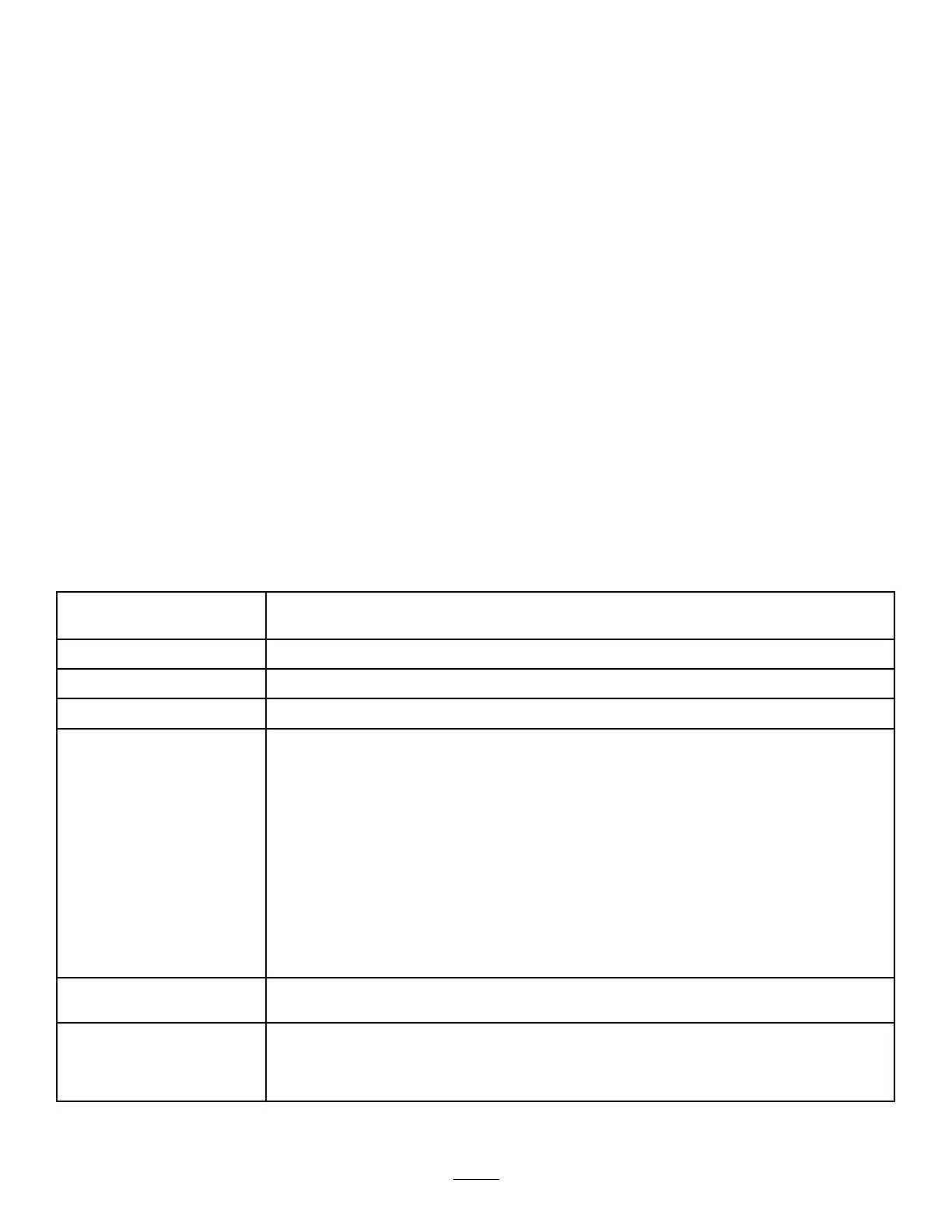

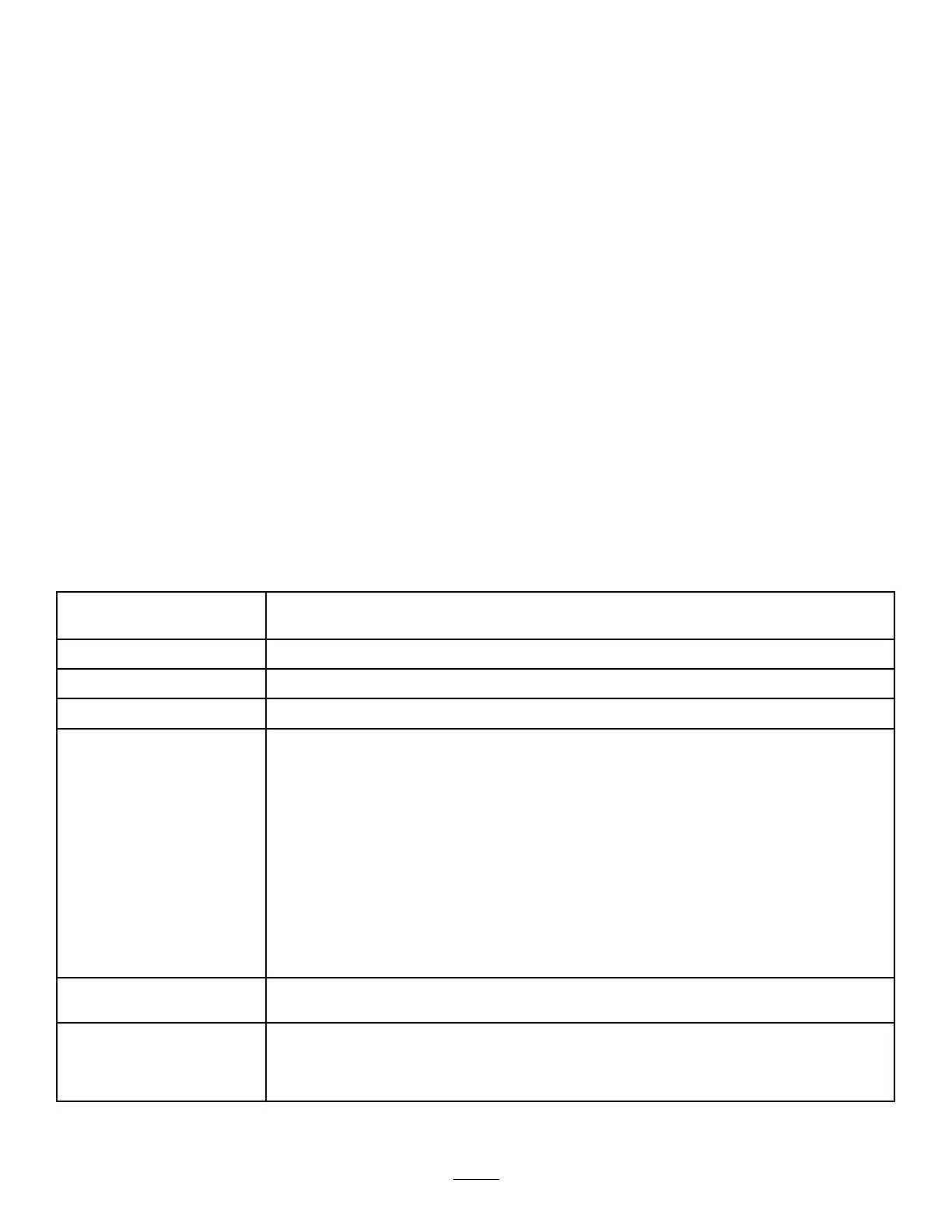

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Afterthersthour

•Torquethewheellugnuts.

Aftertherst10hours

•Torquethewheellugnuts.

Aftertherst50hours

•Checkthealternator-belttension.

Beforeeachuseordaily

•Checktheforwardandreversetractionpedalaction.

•Checktheinterlockswitches:operatorpresence,cutting-unitdriveinterlock,parking

brakeinterlock,andtransmissionneutralinterlock.

•Lubricatethegrease-dailyttings.

•Checktheairlter-blockageindicator.

•Checktheengine-oillevel.

•Drainwaterorothercontaminantsfromthewaterseparator.

•Checkthetireairpressureinthefrontandreartires.

•Removedebrisfromthescreenandradiator/oilcooler.

•Checkthecoolingsystem.

•Checkthehydrauliclinesandhoses.

•Checkthehydraulic-uidlevel.

•Inspecttheseatbelt.

•Checkthefastenersofthemachine.

Every50hours

•Lubricatethegreaseevery50-hourttings.

•Servicethebattery.

Every250hours

•Torquethewheellugnuts.

•Checkthetransmission-controlcable.

•Checkthealternator-belttension.

•Inspectthecooling-systemhoses.

34

Loading...

Loading...