InspectingtheSprayerPump

ServiceInterval:Every400hours/Yearly(whichevercomes

rst)—Inspectthepumpdiaphragmand

replaceifnecessary(seeanAuthorized

ToroServiceDistributor).

Every400hours/Yearly(whichevercomes

rst)—Inspectthepumpcheckvalvesandreplace

ifnecessary(seeanAuthorizedToroService

Distributor).

Note:Thefollowingmachinecomponentsareconsidered

partssubjecttoconsumptionthroughuseunlessfound

defectiveandarenotcoveredbytheWarrantyassociatedwith

thismachine.

HaveanAuthorizedToroServiceDistributorcheckfollowing

internalpumpcomponentsfordamage:

•Pumpdiaphragm

•Pumpcheckvalvesassemblies

Replaceanycomponentsifnecessary.

AdjustingtheActuators

Thefollowingprocedurecanbeusedtoadjustthelengthof

theactuatorrods.

1.Extendtheboomstothesprayposition.

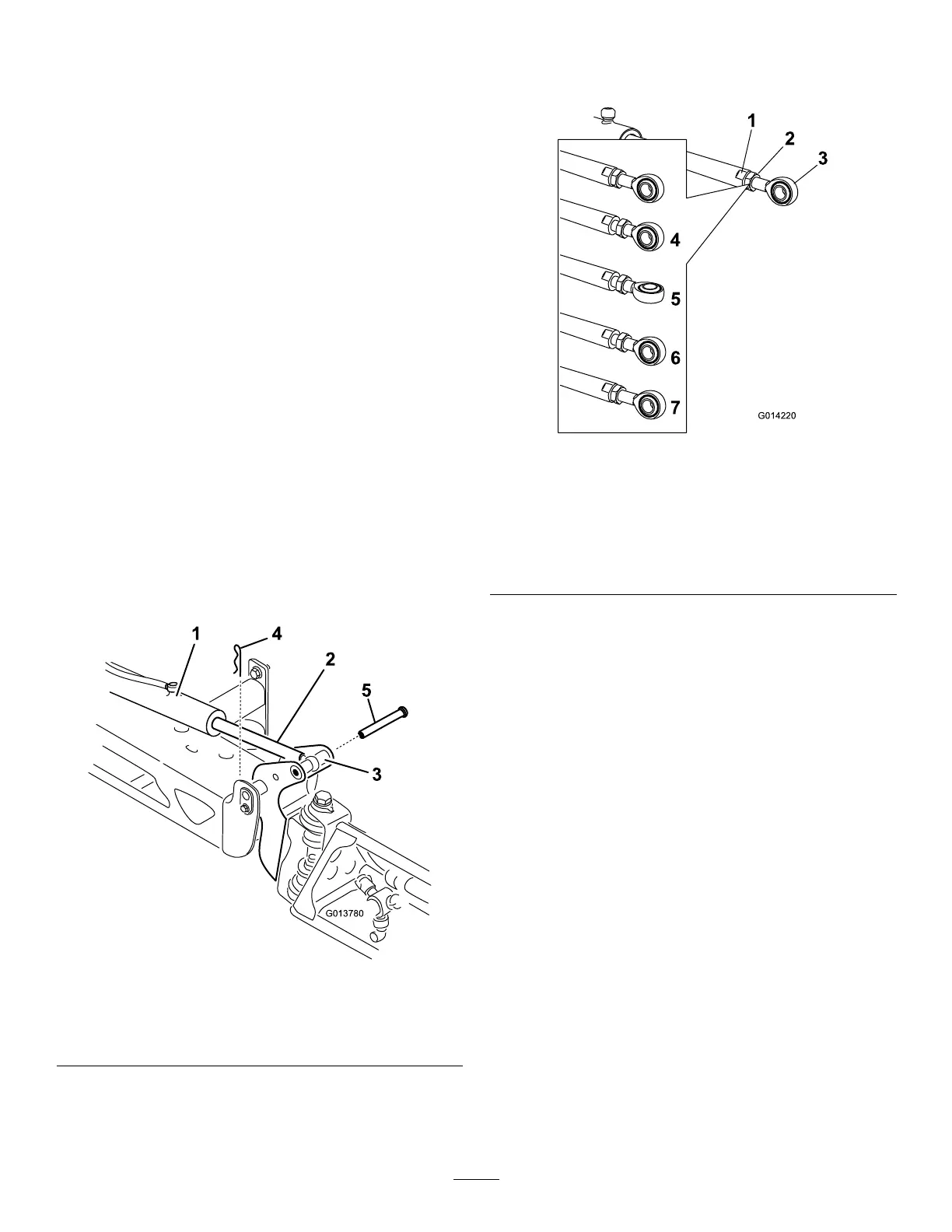

2.Removethecotterpinfromthepivotpin(Figure79).

Figure79

1.Actuator

4.Cotter

2.Actuatorrod5.Pin

3.Boom-pivot-pinhousing

3.Liftupontheboomandremovethepin(Figure79).

Slowlylowertheboomtotheground.

4.Inspectthepinforanydamage,replaceifnecessary.

5.Useawrenchontheatsidesoftheactuatorrodto

immobilizeitthenloosenthejamnuttoallowforthe

eyeletrodtobemanipulated(Figure80).

Figure80

1.Flatontheactuatorrod5.Eyeletadjusted

2.Jamnut

6.Eyeletpositionfor

reassembly

3.Eyelet7.Jamnuttightenedtolock

newposition.

4.Jamnutloosened

6.Turntheeyeletrodintheactuatorrodtoshortenor

lengthentheextendedactuatortothedesiredposition

(Figure80).

Note:Theeyeletrodmustbeturnedinhalfor

completerevolutionstoallowthereassemblyofthe

rodtotheboom.

7.Oncethedesiredpositionhasbeenachieved,tighten

thejamnuttosecuretheactuatorandeyeletrod.

8.Raisetheboomtoalignthepivotwiththeactuatorrod.

Whileholdingtheboom,insertthepinthroughboth

boompivotandactuatorrod(Figure79).

9.Withthepininplace,releasetheboomandsecurethe

pinwiththecotterremovedpreviously.

10.Repeattheprocedureforeachactuatorrodbearingif

necessary.

59