SprayerSystem

Maintenance

WARNING

Chemical substances used in the spray system may

be hazardous and to xic to y ou, bystander s, animals,

plants, soils or other pr oper ty .

•Carefullyreadandfollowthechemical

warninglabelsandMaterialSafetyData

Sheets(MSDS)forallchemicalsusedand

protectyourselfaccordingtothechemical

manufacturer'srecommendations.Forexample,

useappropriatePersonalProtectiveEquipment

(PPE)includingfaceandeyeprotection,gloves,

orotherequipmenttoguardagainstpersonal

contactwiththechemical.

•Keepinmindthattheremaybemorethanone

chemicalusedandinformationoneachshould

beassessed.

•

R efuse to operate or w or k on the spray er if this

inf or mation is not a v aila ble!

•Beforeworkingonaspraysystemmakesurethe

systemhasbeentriplerinsedandneutralized

accordingtotherecommendationsofthe

chemicalmanufacturer(s)andallofthevalves

havebeencycledthreetimes.

•Verifythereisanadequatesupplyofcleanwater

andsoapnearby,andimmediatelywashoffany

chemicalsthatcontactyou.

InspectingtheHoses

ServiceInterval:Every200hours—Inspectallhosesand

connectionsfordamageandproper

attachment.

Every400hours/Yearly(whichevercomes

rst)—InspecttheO-ringsinthevalveassemblies.

ReplacetheO-ringsifnecessary

Examineeachhoseinthespraysystemforcracks,leaksor

otherdamage.Atthesametime,inspecttheconnectionsand

ttingsforsimilardamage.Replaceanyhosesandttingsif

damaged.

ChangingthePressureFilter

ServiceInterval:Every400hours

1.Movethemachinetoalevelsurface,shutoffthe

sprayerpump,shutofftheengine,andremovethekey

fromthestarterswitch.

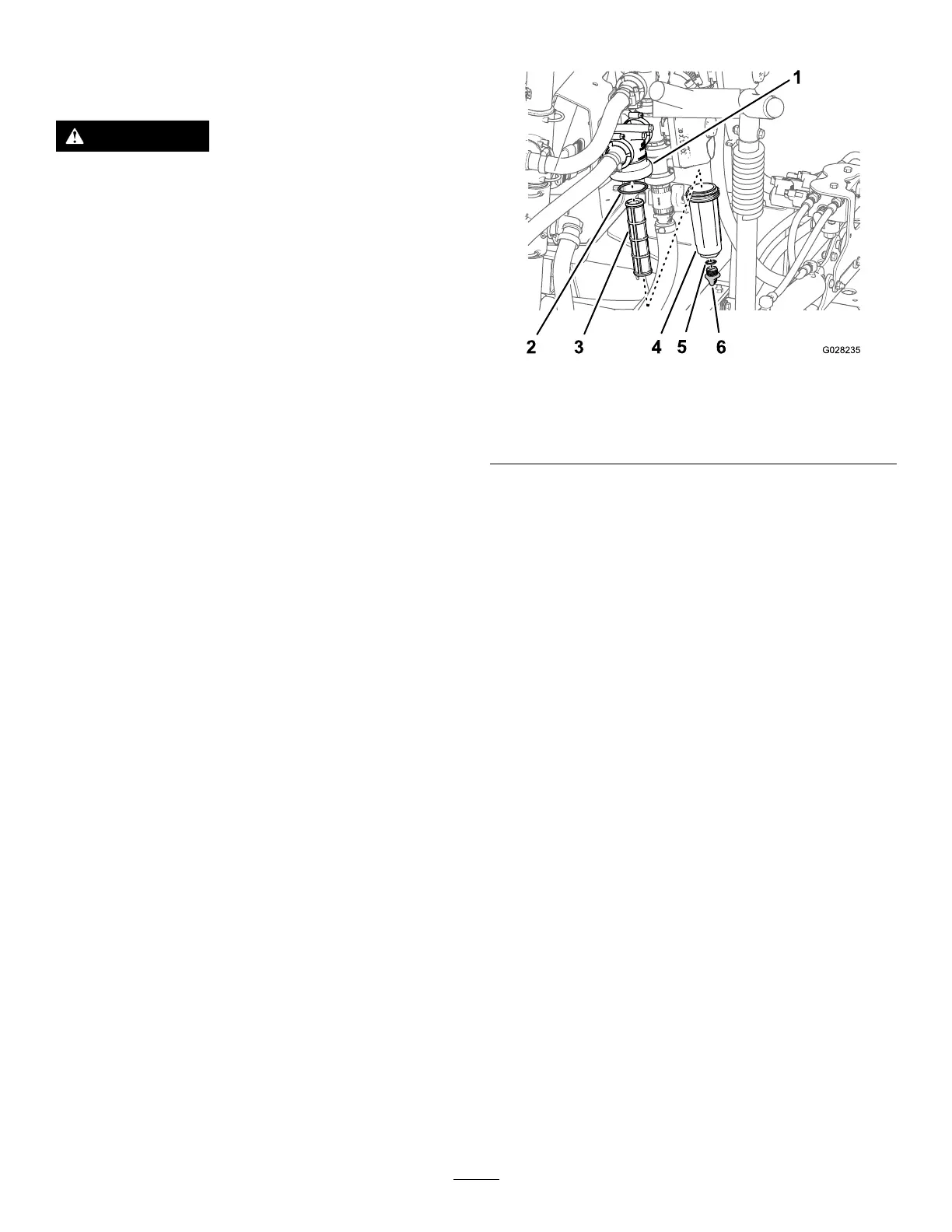

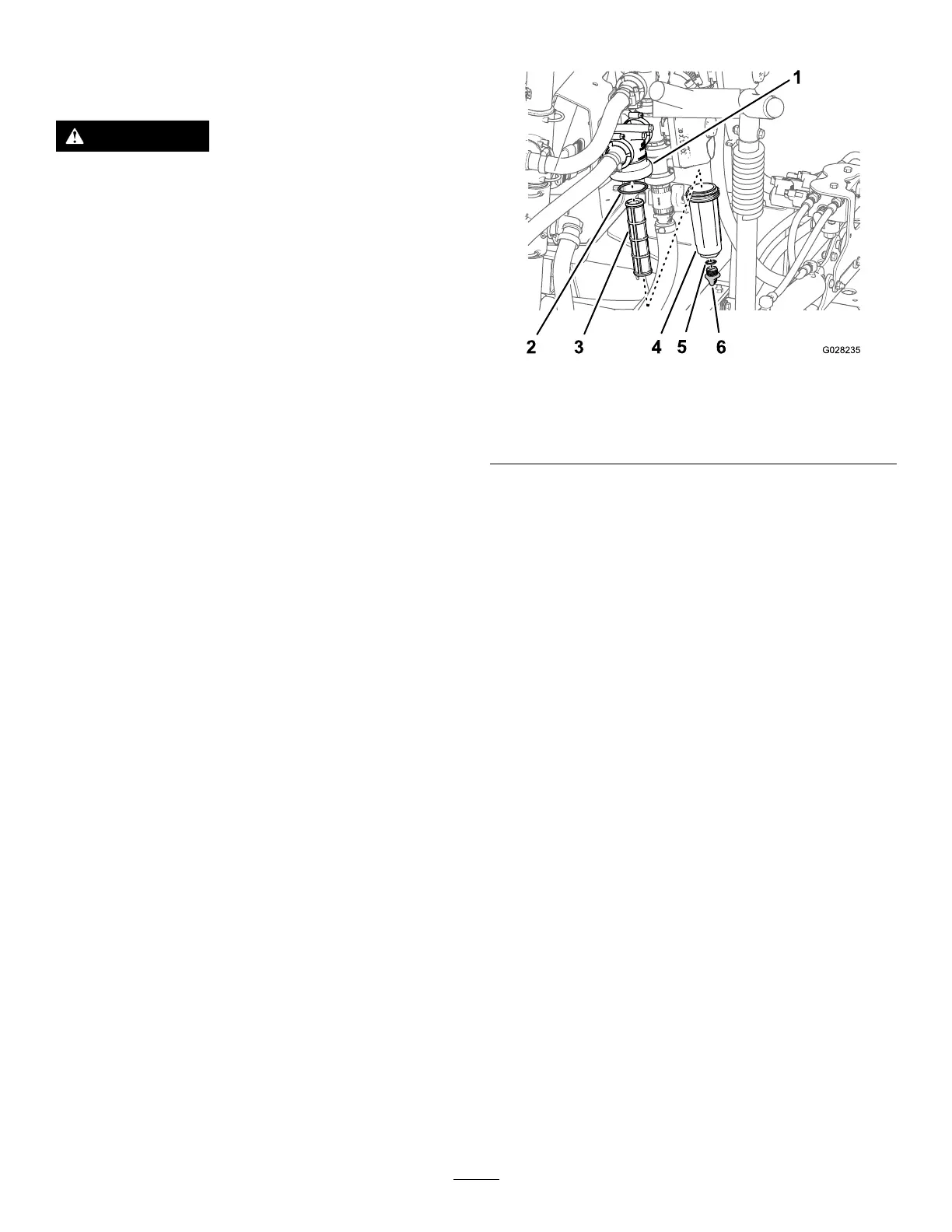

2.Alignadrainpanunderthepressurelter(Figure78).

Figure78

1.Filterhead4.Bowl

2.O-ring(bowl)5.O-ring(drainplug)

3.Filterelement6.Drainplug

3.Rotatethedrainplugcounterclockwiseandremoveit

fromthebowlofthepressurelter(Figure78).

Note:Allowthebowltodraincompletely.

4.Rotatethebowlcounterclockwiseandremoveitlter

head(Figure78).

5.Removetheoldpressurelterelement(Figure78).

Note:Discardtheoldlter.

6.ChecktheO-ringforthedrainplug(locatedinsidethe

bowl)andtheO-ringforbowl(locatedinsidethelter

head)fordamageandwear(Figure78).

Note:ReplaceanydamagedorwornO-ringsforthe

plug,bowl,orboth.

7.Installthenewpressurelterelementintothelter

head(Figure78).

Note:Ensurethatthelterelementisrmlyseated

intothelterhead.

8.Installthebowlontothelterheadhandtight(Figure

78).

9.Installtheplugintothebowlhandtight(Figure78).

58

Loading...

Loading...