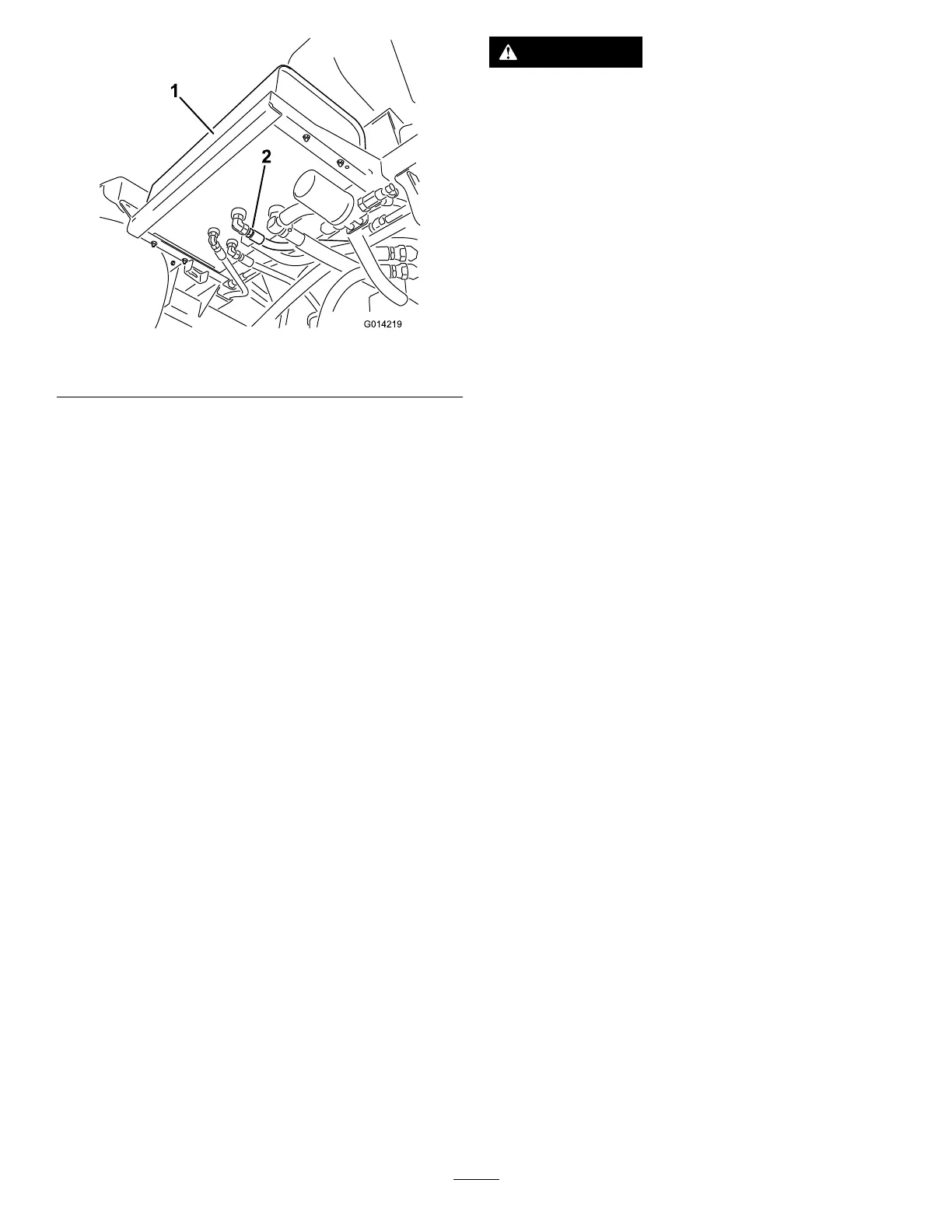

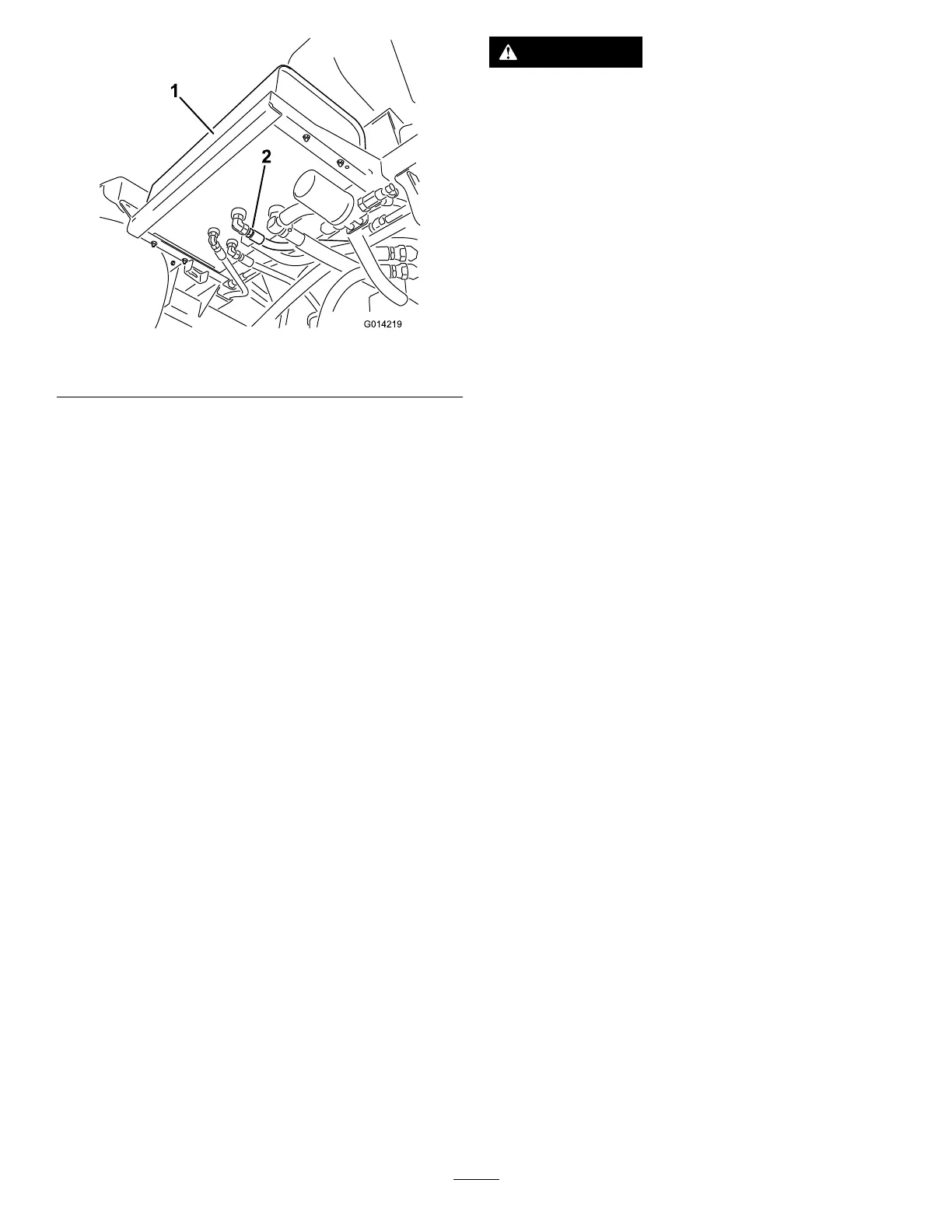

Figure77

1.Hydraulictank

2.Hydraulichoseandtting

3.Placealargepanunderthetting.

4.Removethehosettingfromthetank,allowingtheoil

todrainintothepan(Figure77).

5.Installthehoseandttingtothetankandtightenit

securely.

6.Fillthehydraulicreservoirwithapproximately53L(14

USgallons)ofspeciedhydraulicuidorequivalent,

seeHydraulicFluidSpecication(page55).

7.Startthemachineandrunitatidlefor3to5minutes

tocirculatetheuidandremoveanyairtrappedin

thesystem.

8.Stoptheengine,checkthehydraulicoillevel,andcheck

forleaks.

9.Disposeoftheusedoilatacertiedrecyclingcenter.

CheckingtheHydraulicLinesand

Hoses

Inspectthehydrauliclinesandhosesdailyforleaks,kinked

lines,loosemountingsupports,wear,loosettings,weather

deteriorationandchemicaldeterioration.Makeallnecessary

repairsbeforeoperating.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Ensurethatallhydraulicuidhosesandlinesare

ingoodconditionandallhydraulicconnections

andttingsaretightbeforeapplyingpressureto

thehydraulicsystem.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

•Getimmediatemedicalhelpifuidisinjected

intoskin.

57

Loading...

Loading...