20

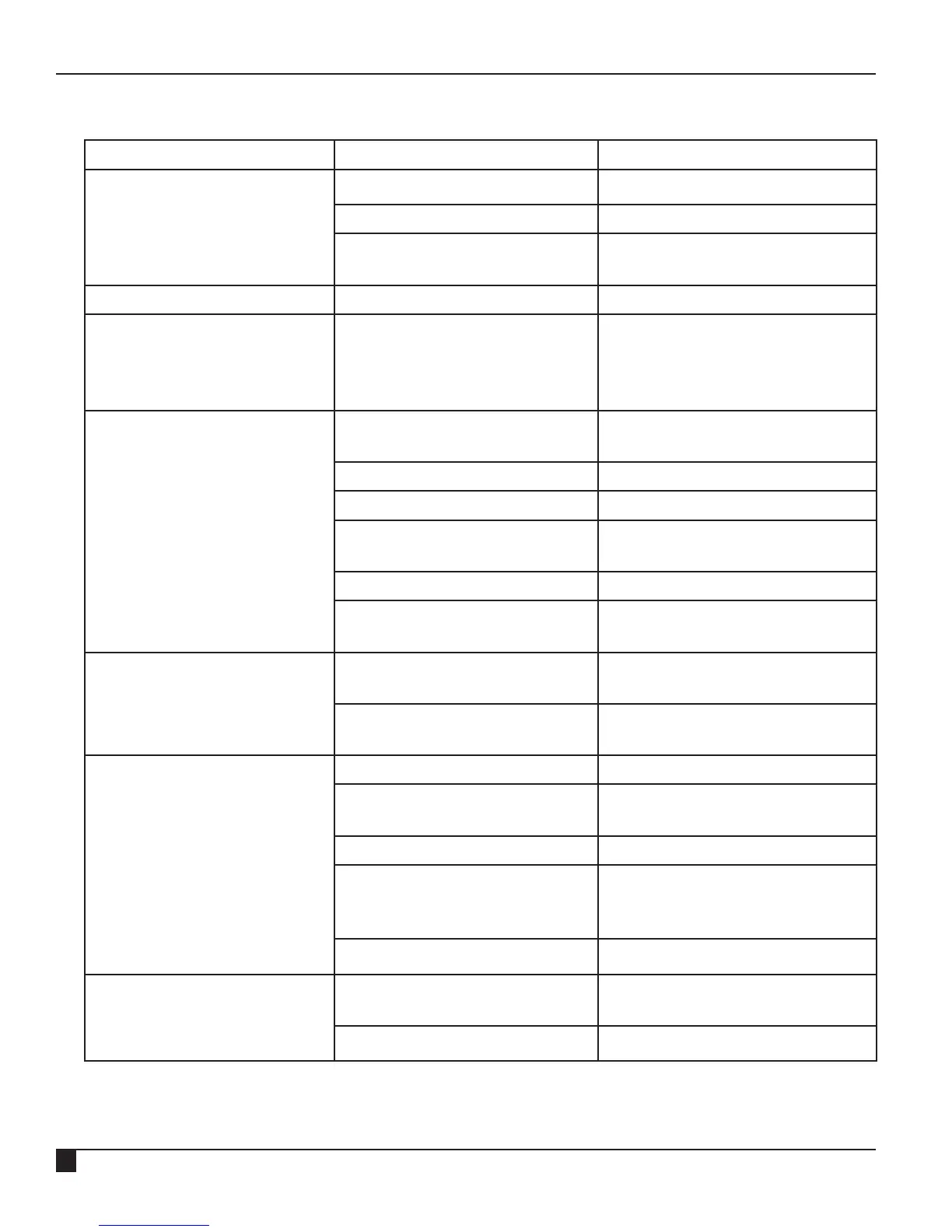

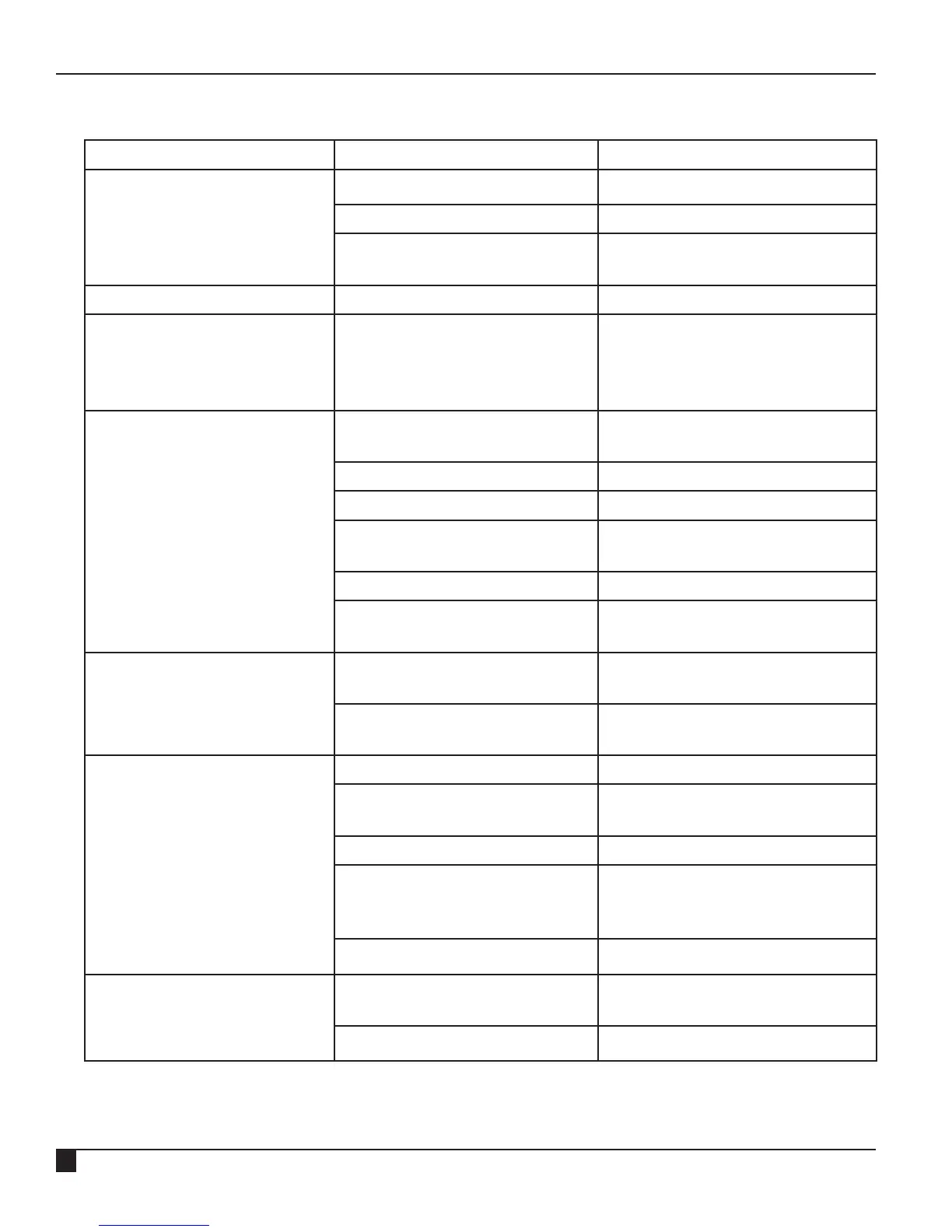

9. Troubleshooting

9.1 Sprinkler malfunctions

Malfunction Cause Remedy

Sprinkler not rotating or only

very slowly.

Sprinkler not rotating at all.

Sealing disc worn out Change sealing disc

Driving nozzle clogged Unscrew driving nozzle and clean

Minimum pressure of 43.5 psi not

reached

Increase pressure

Sprinkler has poor jet Nozzle is blocked Unscrew nozzle, remove and clean.

Sector angle gets bigger during

operation.

Spring stop is loose.

Spring force has slackened.

Spring stop has been

overextended.

Fit new spring stop.

Valve opens/closes only with

manual opening, but not on any

electric signal

Screw for <Manual opening> is set

to OFF

Turn screw to the left as far as it will

go, to Auto.

Core is jammed in the coil Remove coil and clean core

No / inadequate power supply Establish 24V AC power supply

Defective coil Check coil resistance (should be ap-

prox. 35 ohms). Replace if necessary.

Relief channel for coil blocked Clean channel

Control pipe to the solenoid

clogged or bent

Replace control pipe

Valve fails to open even with

manual opening

Control water hole or relief hole

blocked

Clean control water / relief hole

Supply line under no / insucient

pressure

Establish pressure supply

Valve fails to close

Coil seat dirty Clean coil seat

Bits of dirt between valve seat and

sealing plate

Clean valve seat and sealing plate

Defective membrane Remove valve and replace membrane

Control water lter dirty or

Control water lter of the valve

lter dirty

Clean control water lter

Control pipe defect Change control pipe

Output pressure at sprinkler

nozzle too low or casting range

too short

Stones and bits of dirt are hinder-

ing an unimpeded passage of water

Clean valve and ush sprinkler

Valve insert is blocked Clean valve insert see point 8.3

We reserve the right to make changes in line with technological advances, including without prior notication.

Loading...

Loading...