MaintenanceService

Interval

MaintenanceProcedure

Every100hours

•Changetheengineoil.(Servicemorefrequentlyifconditionsareextremelydusty

orsandy.)

•Checkandadjustthetracktension.

•Checkthecoolingsystemhoses.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeterioration.

•Checkfordirtbuildupinthechassis.

•Checkthealternator/fanbelttension(refertotheengineowner’smanualfor

instructions).

Every200hours

•Changetheoillter.(Servicemorefrequentlyifconditionsareextremelydusty

orsandy.)

•Replacethehydrauliclter.

Every250hours

•Checkandgreasetheroadwheels.

Every400hours

•Checkthefuellinesandconnectionsfordeterioration,damage,orlooseconnections.

•Replacethefuelltercanisterandin-linelter.

•Changethehydraulicuid.

Every500hours

•Replacethealternator/fanbelt(refertotheengineowner’smanualforinstructions).

Every1,500hoursor

2years,whichever

comesrst

•Replaceallmovinghydraulichoses.

Yearly

•Changetheenginecoolant.

•Checktheconditionofthehydraulicpumpbelt.

Yearlyorbeforestorage

•Checkandadjustthetracktension.

•Touchupchippedpaint.

Every2years

•Drainandcleanthefueltank(s)—AuthorizedServiceDealeronly.

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

Pre-Maintenance

Procedures

UsingtheCylinderLock

WARNING

Theloaderarmsmaylowerwhenintheraised

position,crushinganyoneunderthem.

Installthecylinderlock(s)beforeperforming

maintenancethatrequiresraisedloaderarms.

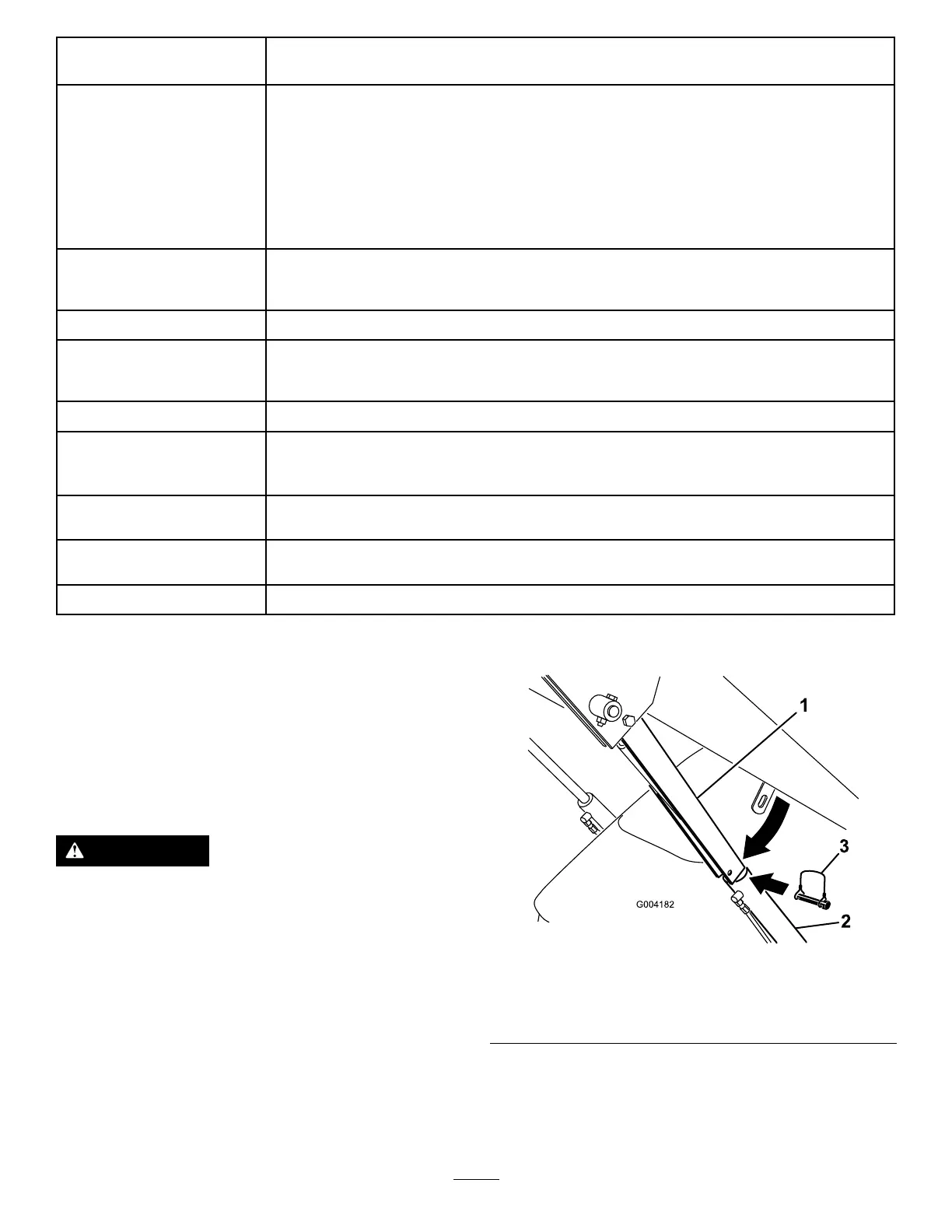

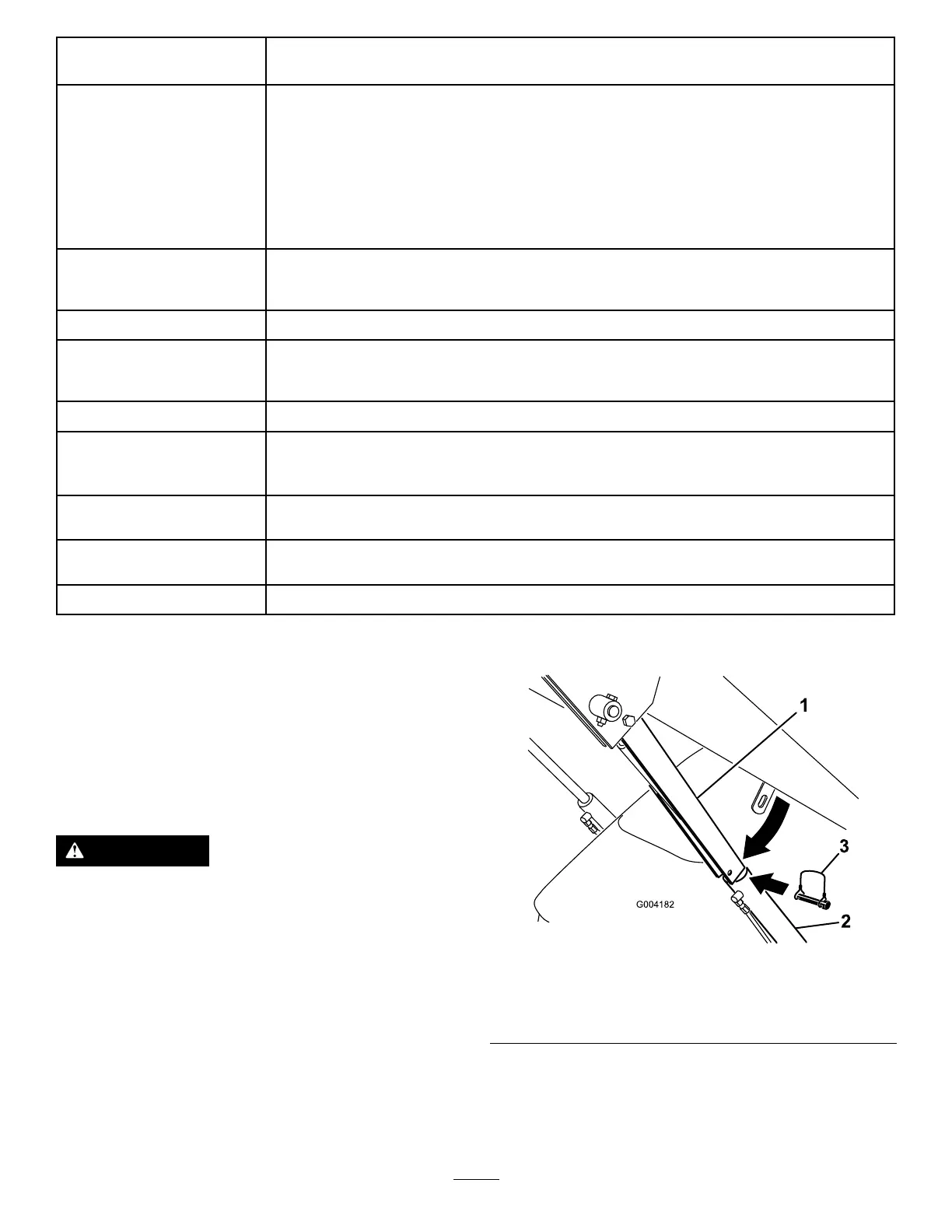

InstallingtheCylinderLock

1.Removetheattachment.

2.Raisetheloaderarmstothefullyraisedposition.

3.Shutofftheengineandremovethekey.

4.Removethelynchpinsecuringthecylinderlock

totheloaderarm(Figure23).

g004182

Figure23

1.Cylinderlock

3.Lynchpin

2.Liftcylinder

5.Lowerthecylinderlockoverthecylinderrodand

secureitwiththelynchpin(Figure23).

6.Slowlylowertheloaderarmsuntilthecylinder

lockcontactsthecylinderbodyandrodend.

23

Loading...

Loading...