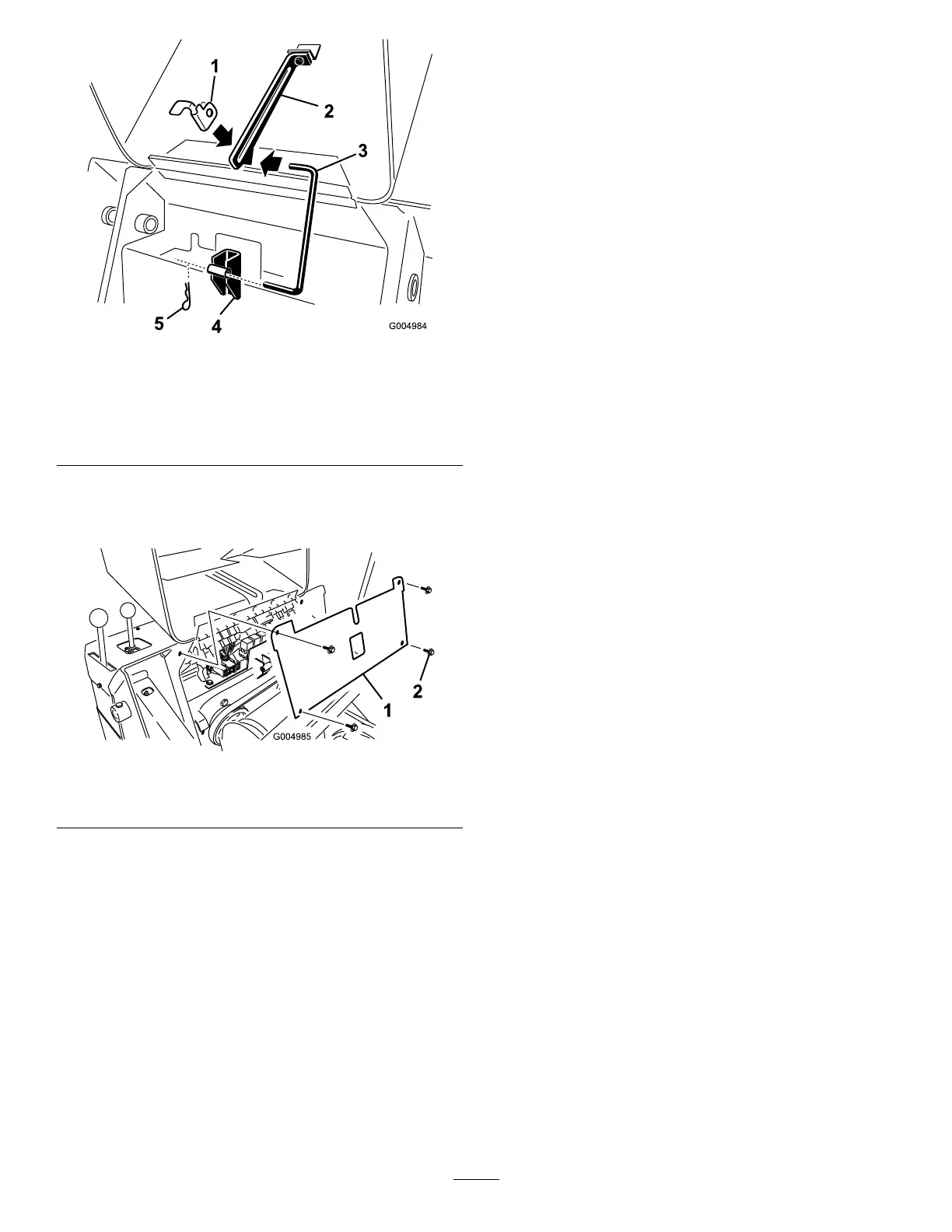

g004984

Figure41

1.Prop-rodtab4.Retaining

bracket—bottom

2.Retainingbracket—top5.Hairpincotter

3.Prop-rod

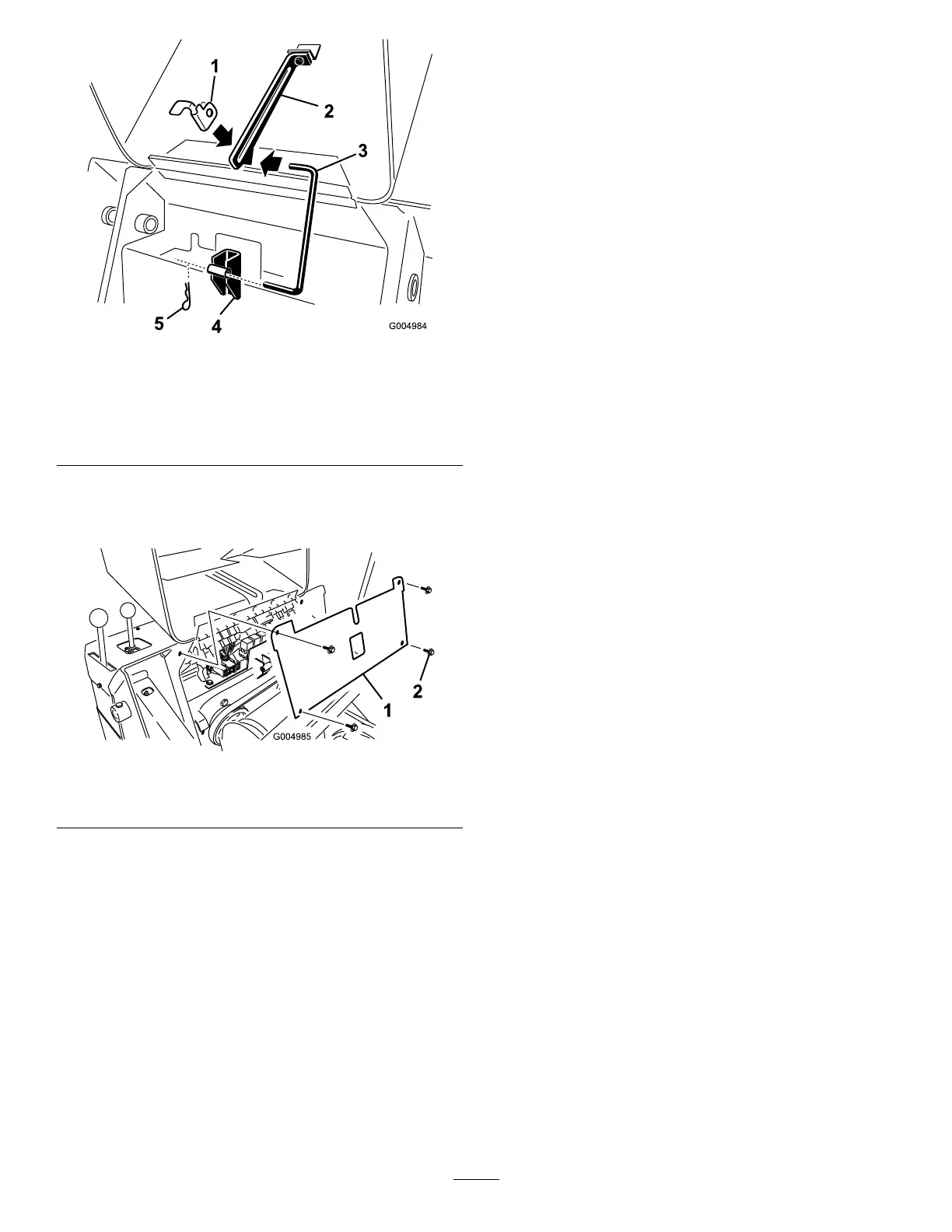

5.Removethe4screwssecuringthefusepanel

andthenpullthepaneloutanduptoremove

it(Figure42).

g004985

Figure42

1.Fusepanel

2.Screw

6.Checkthefuses.

7.Installthefusepanelusingthe4screws

removedpreviously.

8.Installtheprop-rodintotheretainingbrackets

andprop-rodtabandsecureitwiththehairpin

cotter(Figure41).

9.Closethehood.

DriveSystem

Maintenance

ServicingtheTracks

ServiceInterval:Aftertherst50hours—Checkand

adjustthetracktension.

Beforeeachuseordaily—Cleanthetracks.

Beforeeachuseordaily—Checkthetracksfor

excessivewear(Ifthetracksareworn,replace

them).

Every100hours—Checkandadjustthetrack

tension.

Every250hours/Yearly(whichevercomes

rst)—Checkandgreasetheroadwheels.

CleaningtheTracks

1.Parkthemachineonalevelsurfaceandengage

theparkingbrake.

2.Withthebucketinstalledandpointingdown,

loweritintothegroundsothatthefrontofthe

tractionunitliftsoffthegroundafewcentimeters

(inches).

3.Shutofftheengineandremovethekey.

4.Usingawaterhoseorpressurewasher,remove

dirtfromeachtracksystem.

Important:Ensurethatyouusehigh-pressure

watertowashonlythetrackarea.Donotuse

ahigh-pressurewashertocleantherestofthe

machine.Donotusehighpressurewaterbetween

thedrivesprocketandthemachineoryoumay

damagethemotorseals.High-pressurewashing

candamagetheelectricalsystemandhydraulic

valvesordepletegrease.

Important:Ensurethatyoufullycleantheroad

wheels,thetensionwheel,andthedrivesprocket

(Figure43).Theroadwheelsshouldrotatefreely

whenclean.

34

Loading...

Loading...