AdjustingtheTrackingofthe

TractionControl,FullForward

Position

Ifthemachinedoesnotdrivestraightwhenyou

holdthetractioncontrolagainstthereferencebar,

completethefollowingprocedure:

1.Drivethemachinewiththetractioncontrol

againstthereferencebar,notingwhichdirection

thetractionunitveers.

2.Releasethetractioncontrol.

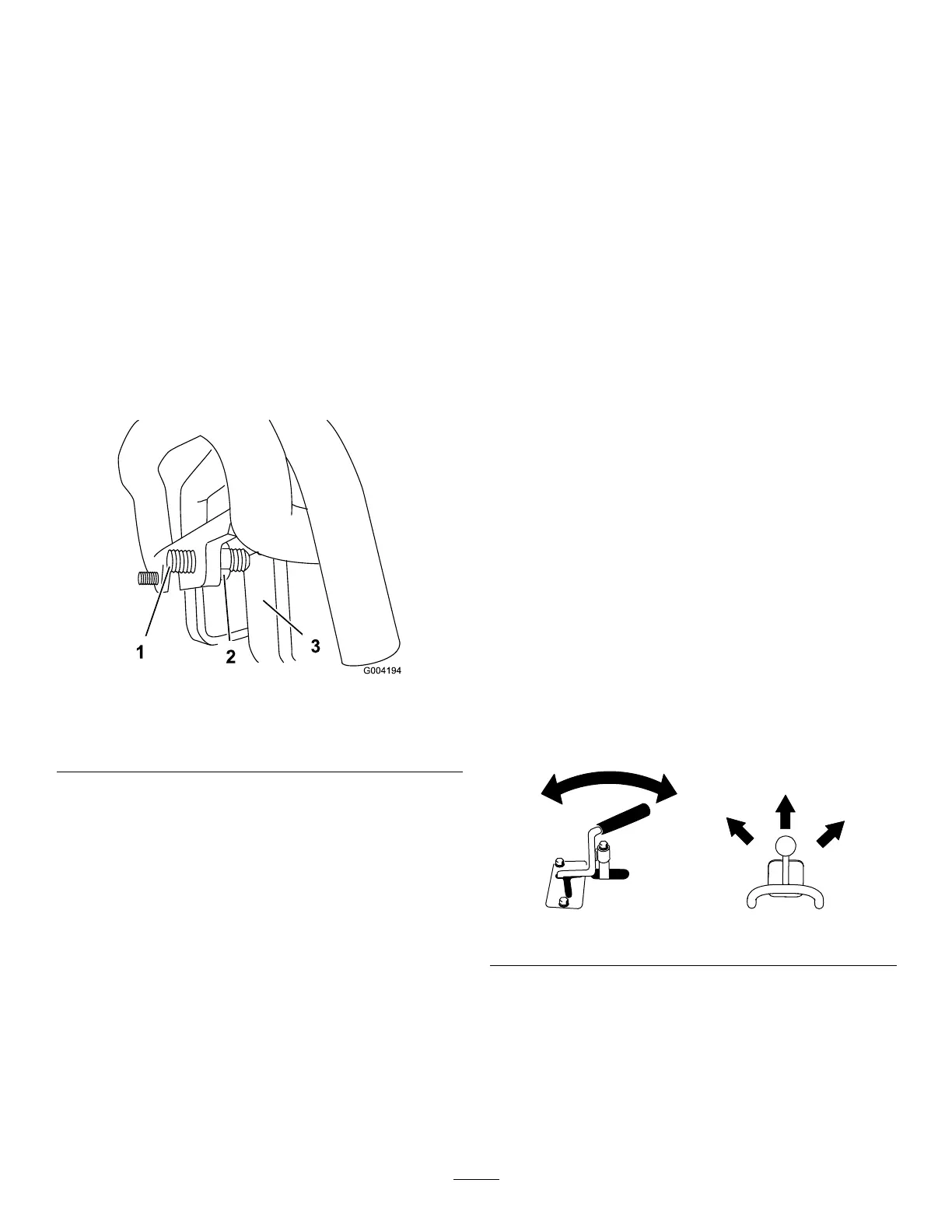

3.Ifthetractionunitveerstotheleft,loosenthe

rightjamnutandadjustthetrackingsetscrew

onthefrontofthetractioncontrol(Figure57).

4.Ifthetractionunitveerstotheright,loosenthe

leftjamnutandadjustthetrackingsetscrewon

thefrontofthetractioncontrol(Figure57).

g004194

Figure57

1.Setscrew3.Stop

2.Jamnut

5.Repeatsteps1through4untilthemachine

drivesstraightinthefullforwardposition.

Important:Ensurethatthetrackingset

screwstouchthestopsinthefullforward

positiontoavoidoverstrokingthehydraulic

pumps.

HydraulicSystem

Maintenance

HydraulicSystemSafety

•Seekimmediatemedicalattentionifuidisinjected

intoskin.Injecteduidmustbesurgicallyremoved

withinafewhoursbyadoctor.

•Ensurethatallhydraulic-uidhosesandlinesare

ingoodconditionandallhydraulicconnections

andttingsaretightbeforeapplyingpressureto

thehydraulicsystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressurehydraulic

uid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

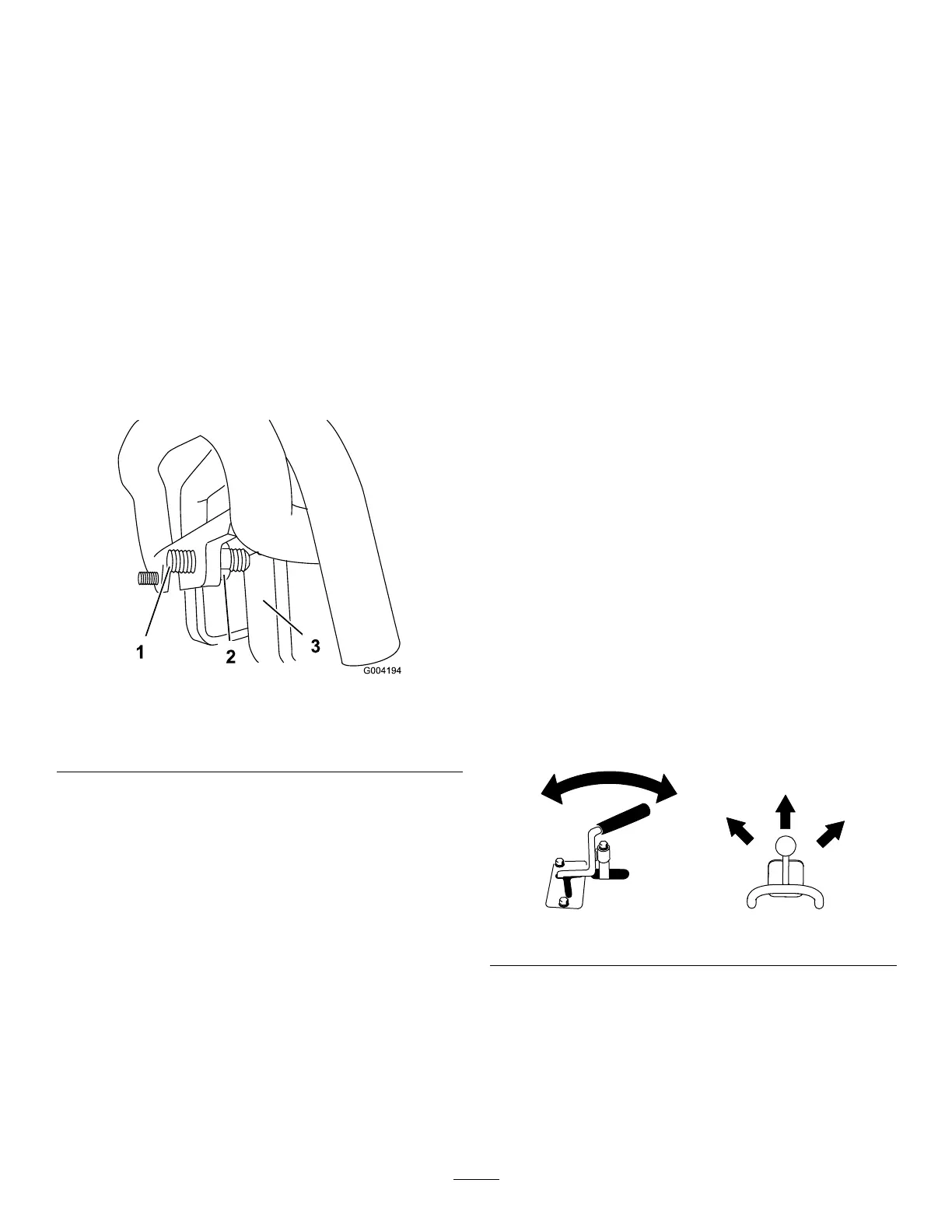

RelievingHydraulic

Pressure

Torelievehydraulicpressurewhiletheengineison,

disengagetheauxiliaryhydraulicsandfullylowerthe

loaderarms.

Torelievethepressurewhiletheengineisoff,move

theauxiliary-hydraulicsleverbetweentheforwardand

reverseowpositionstorelieveauxiliaryhydraulic

pressure,andcycletheloader-arm/attachment-tilt

leverbetweentheforwardpositionstolowerthe

loaderarms(Figure58).

g280733

Figure58

42

Loading...

Loading...