Adjusting the

Motion-Control Linkage

Located on either side of the machine, below the seat,

are the pump-control linkages. Rotating the end nut

with a 1/2-inch deep socket wrench allows ne tuning

adjustments so that the machine does not move in

neutral. Any adjustments should be made for neutral

positioning only .

W ARNING

The engine must be running and the drive

wheels turning so that you can perform the

adjustments. Contact with moving parts or

hot surfaces may cause personal injury .

Keep your ngers, hands, and clothing clear

of rotating components and hot surfaces.

1. Park the machine on a level surface, disengage

the blade-control switch (PT O), and engage the

parking brake.

2. Shut of f the engine, remove the key , and wait

for all moving parts to stop before leaving the

operating position.

3. Push the deck-lift pedal, remove the height-of-cut

pin, and lower the mower deck to the ground

4. Raise the rear of the machine up and support it

with jack stands (or equivalent support) just high

enough to allow the drive wheels to turn freely .

5. Remove the electrical connection from the seat

safety switch, located under the bottom cushion

of the seat.

Note: The switch is a part of the seat assembly .

6. T emporarily install a jumper wire across the

terminals in the connector of the main wire

harness.

7. Start the engine, run it at full throttle, and

disengage the parking brake.

Note: Before starting the engine, ensure that

the parking brake is engaged and that the

motion-control levers are out. Y ou do not have

to be in the seat.

8. Run the machine at least 5 minutes with the

drive levers at full forward speed to bring the

hydraulic uid up to the operating temperature.

Note: The motion-control levers must be in

neutral while you are making any adjustments.

9. Bring the motion-control levers into the N EUTRAL

position.

10. Check and ensure that the control-plate tabs

touch the return-to-neutral plates on the

hydraulic units.

1 1. Adjust the pump-control-rod lengths by rotating

the nut in the appropriate direction until the

wheels slightly creep in reverse ( Figure 81 and

Figure 82 ).

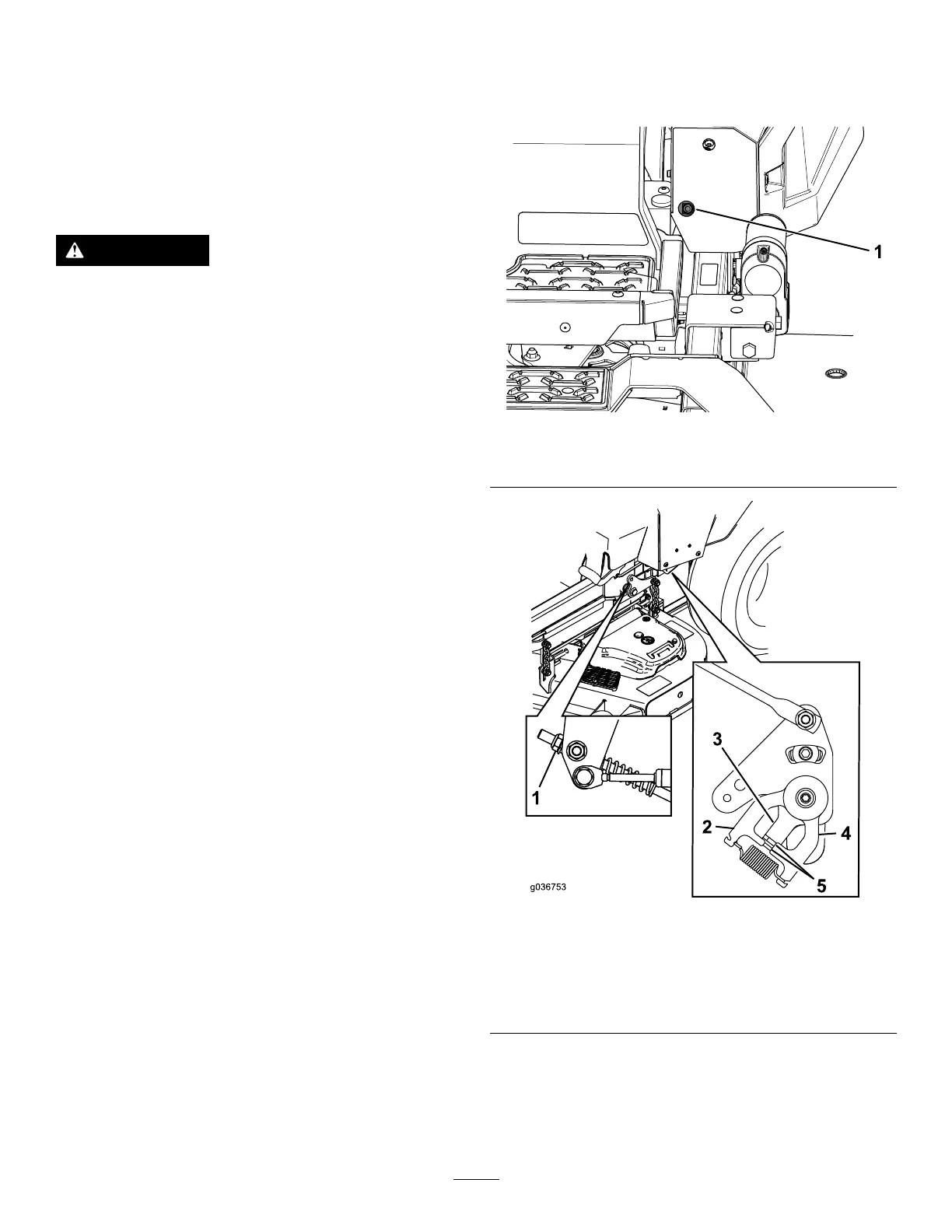

g334848

Figure 81

1. Access hole for 1/2-inch socket

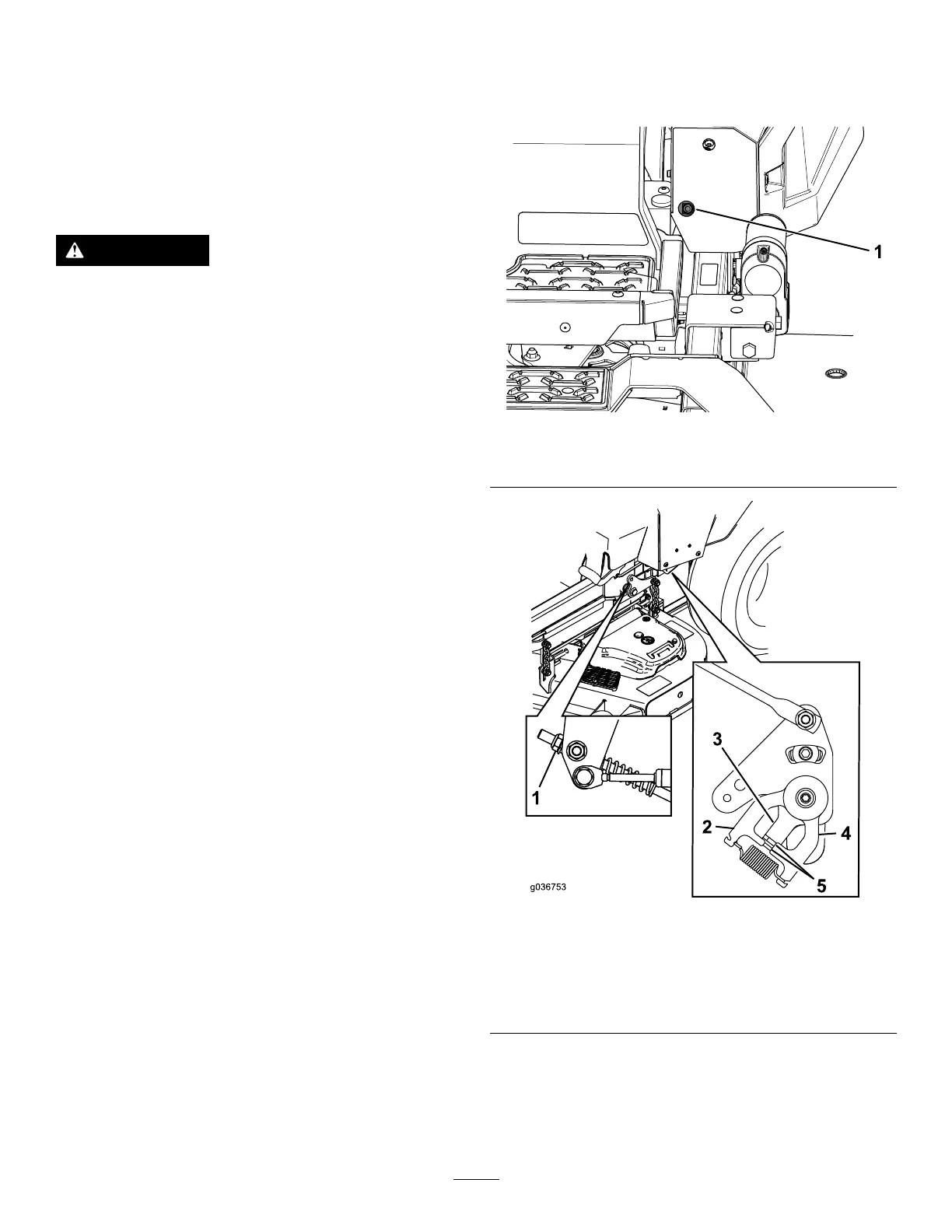

g036753

Figure 82

1. Nut 4. Return-to-neutral plate

2. Stationary plate

5. T abs touching return to

neutral plate

3. Control plate

12. Move the motion-control levers to the R EVERSE

position and while applying slight pressure to

the lever , allow the reverse-indicator springs to

bring the levers back to neutral.

61

Loading...

Loading...