© 2008 Trane 2 18-GE08D1-6

Installer’s Guide

Manual D, Manual S and Manual RS along with the

air handler Product Data and Service Facts for addi-

tional information.

5. The area around refrigerant lines must be sealed

and electrical inlets need to be sealed at both the

low and the high voltage.

6. It is recommended that the outline drawing be

studied and dimensions properly noted and checked

against selected installation site. By noting in ad-

vance which knockouts are to be used, proper clear-

ance allowances can be made for installation and

possible future service.

7. Allow a minimum of 21 inches clearance in

front of the air handler to permit service and re-

moval of filter.

8. When air handler with supplementary heater is to

be installed in the downflow position on combus-

tible flooring an accessory subbase (TAYBASE101

for 2TEC3F18-36B, TAYBASE102 for 2TEC3F55 and

TAYBASE100 for 2TEC3F42B-60B) must be used.

See Figure 1.

9. If supplementary heat is to be added, power supply

must be sufficient to carry the load. In addition,

minimum air flow settings, unit and duct clearances

to combustible material must be maintained as

stated on the air handler rating nameplate.

These air handlers are suitable for installation in a

closet, alcove or utility room with free, non-ducted, air

return, using the area space as a return air plenum.

With ducted supply air, if the minimum clearances to

combustible materials and service access are observed,

the above installations are suitable.

This area may also be used for other purposes, includ-

ing an electric hot water heater – but in no case shall

a fossil fuel device be installed and/or operated in

the same closet, alcove or utility room.

In addition, these air handlers are suitable for installa-

tion in an attic, garage or crawl space with ducted sup-

ply and return air.

This equipment has been evaluated in accordance with

the Code of Federal Regulations, Chapter XX, Part 3280

or the equivalent. “SUITABLE FOR MOBILE HOME

USE.”

For proper installation the following items must be con-

sidered:

1. If adequate power is available and correct according

to nameplate specifications.

2. Insulate all ducts, particularly if unit is located out-

side of the conditioned space.

3. Pursuant to Florida Building Code 13-610.2.A.2.1,

this unit meets the criteria for a factory sealed

air handler.

4. To ensure maximum efficiency and system perfor-

mance, the existing supply and return duct system

static pressures must not exceed the total available

static pressure of the air handler. Reference ACCA

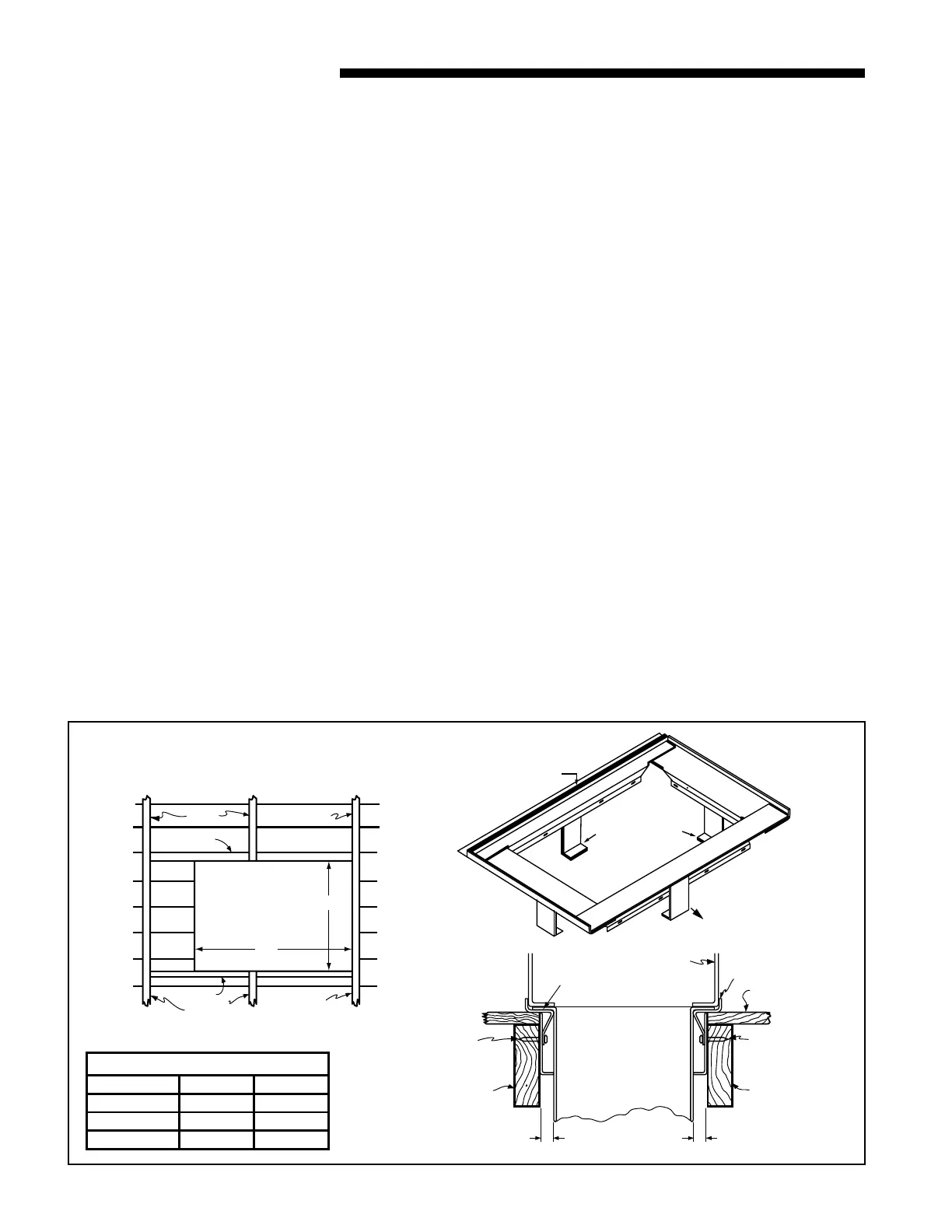

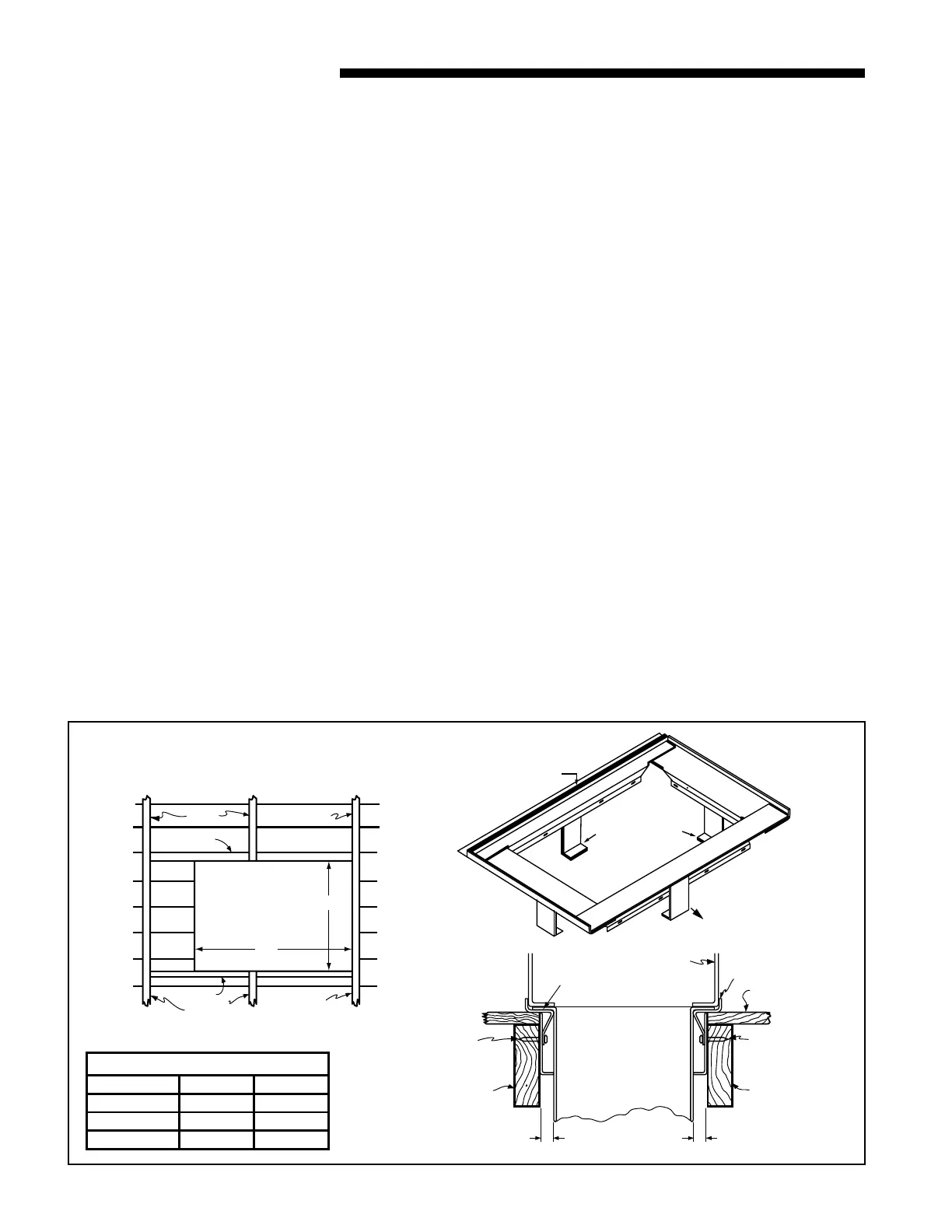

B

A

JOIST

JOIST

JOISTS

HEADER

JOISTS

HEADER

NAILS

REAR

FLANGE

FRONT OF

UNIT

HEADER

1"

NAILS

HEADER

MIN. SPACING TO

ANY COMBUSTIBLE

MATERIAL.

1"

APPROX. 3/4" FLANGES ON FIELD

FABRICATED DUCT OR PLENUM

ONE INCH DUCT SPACERS

FLOOR

SUBBASE

UNIT

AIR HANDLER SUBBASE

1

FLOOR OPENING - SIZE

MODEL NO. A B

TAYBASE100 23-3/4 14-13/16

TAYBASE101 21-3/4 14-13/16

TAYBASE102 26-3/4 14-13/16

Loading...

Loading...