Loading...

Loading...

Do you have a question about the Trane CenTraVac and is the answer not in the manual?

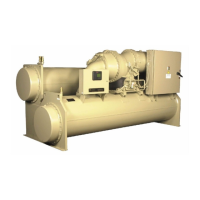

| Compressor Type | Centrifugal |

|---|---|

| Dimensions | Varies by model |

| Frequency | 50/60 Hz |

| Refrigerant | R-123 or R-134a |

| Operating Range | 40°F to 65°F (Leaving Chilled Water Temperature) |

Overview of the manual's scope and purpose for chiller installation.

Glossary of technical terms and abbreviations used in the document.

Explanation of the unit's identifier and its components.

Details found on the unit's identification plate.

Conversion factors for measurements used in the manual.

Key duties and tasks for contractors during unit installation.

Guidelines for meeting safety standards for equipment rooms.

Information regarding the factory packaging and initial inspection of the chiller.

Precautions for storing the chiller before installation.

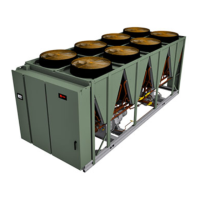

Required space around the chiller for service and maintenance.

Conditions to consider for the chiller's installation location.

Specific guidelines for storing the unit when not immediately installed.

Criteria for preparing a stable and rigid mounting surface for the chiller.

Recommended methods and safety precautions for lifting and moving the chiller.

Methods to minimize vibration and sound transmission from the chiller.

Details on the placement and use of isolation pads under the chiller.

Instructions for installing and adjusting spring isolators for vibration control.

Procedures for ensuring the chiller is installed perfectly level.