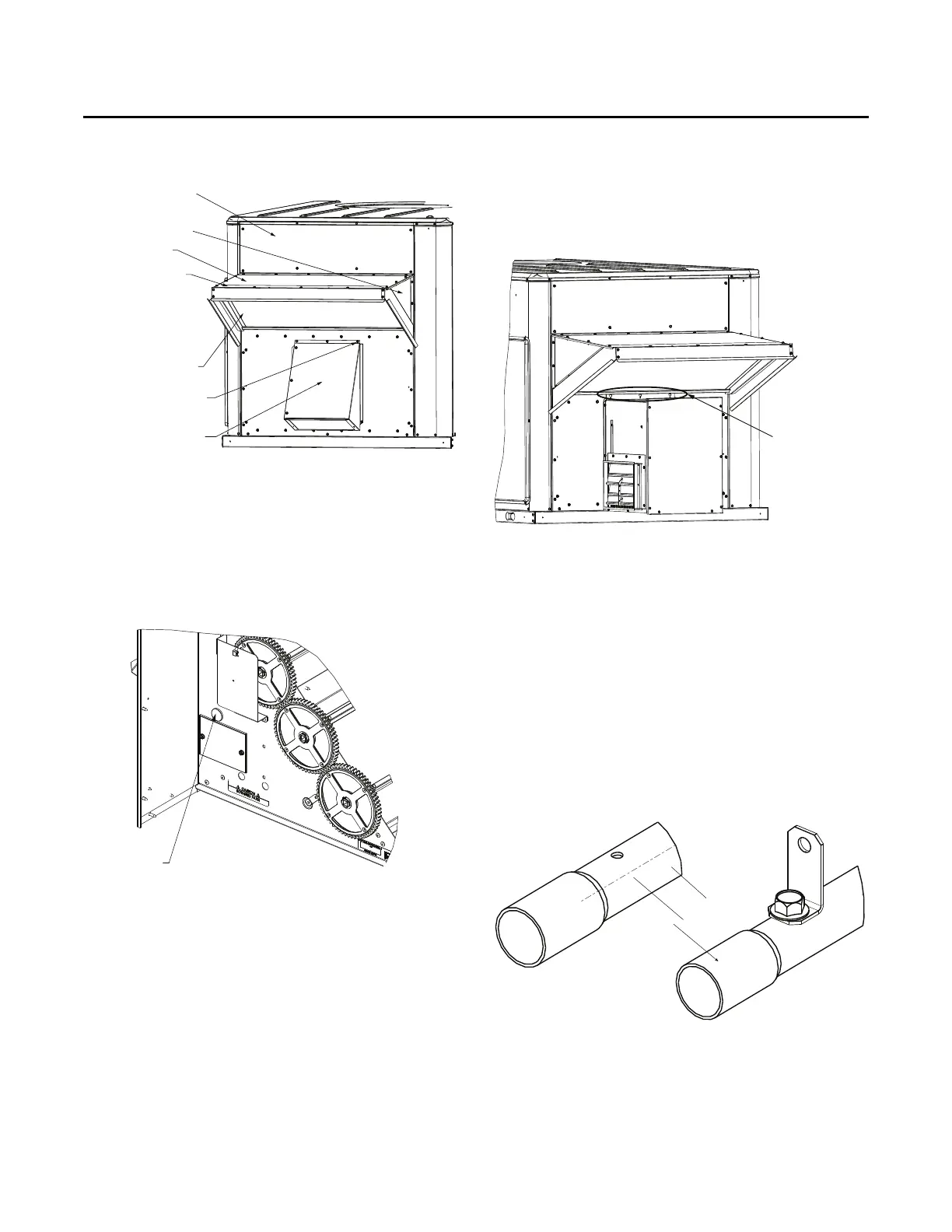

Figure 4. Barometric relief hood

Hood Triangle

Dimples for Powered

Exhaust Screws

Hood Top

Filler Panel

Mist Eliminator

FA Hood Front

Support

Barometric Relief

Hood

Installation - FIAECON102*

ACC-SVN264B-EN 7

Powered Exhaust

1. Remove aluminum barometric relief blade and discard.

2. Open 1-inch hole near the gear side of the economizer and

install

1-inch grommet.

Note: Gro

mmet in economizer parts bag.

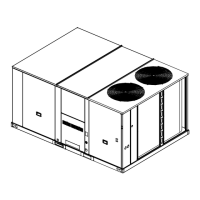

Figure 5. Gear side of the economizer

1-inch Hole

for Wire Routing

3. Partially insert self-drilling screws in three dimples above

power exhaust opening and just below top economizer

hood. See Figure 6.

Note: Do not re-use baro

metric relief damper holes.

4. Install gasketing around perimeter of powered exhaust

assembly

.

5. Route the powered exhaust wire harness through the 1-

inch

hole near the gear side of the economizer.

6. Hang powered exhaust on three partially inserted screws

and

remove the slack in wire harness.

7. Attach powered exhaust with self-drilling screws. See

Figure 6.

8. Verify wire harness is clear of gears, doors, and any sharp

edges of metal.

9. Hook up electrical as described in literature

ACC-SVN57*-EN.

Figure 6. Powered exhaust

Dimples for

Powered Exhaust

Screws

Smoke Detector

1. If a smoke detector is installed, remove the copper or

aluminum pipe, and flexible tubing from above return air

opening, and all associated brackets.

Note: Grommets

are in the economizer parts bag.

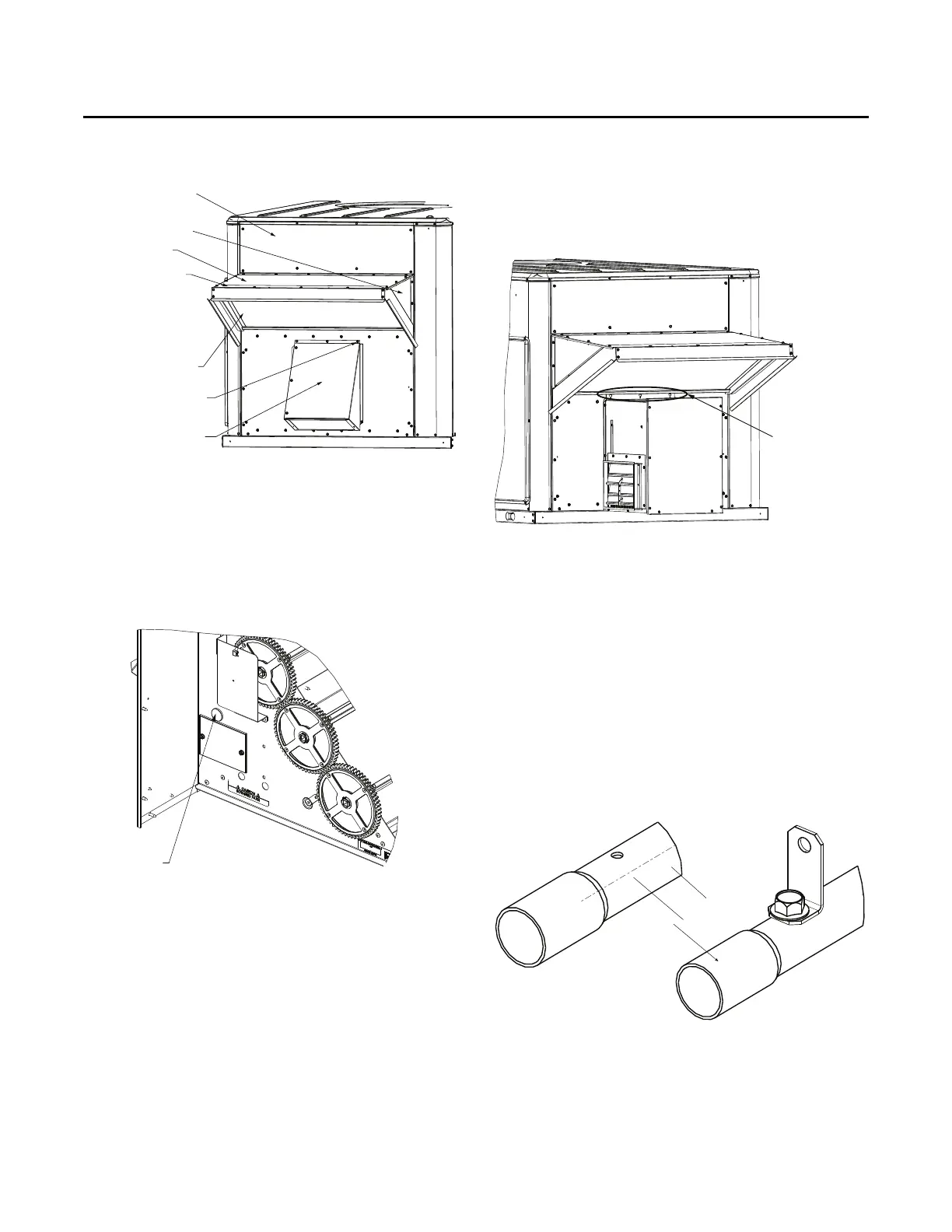

2. Attach retaining bracket to pipe. See Figure 7 for the large

e

conomizer, drill a 1/8-inch hole drilled in pipe on opposite

side of existing breathing holes.

Notes:

• Re

taining bracket in the economizer parts bag.

• In Figure 7, intake holes must be down for unit to work.

Figure 7. Tubing

1/2-inch

3. Insert smoke detector pipe into hole of economizer (next to

RTEM board) and into back bracket inside economizer.

4. Using a self-drilling screw, attach retaining bracket to

e

conomizer. See Figure 8, p. 8.

5. Shorten flexible tubing and connect from the copper tubing

to the smo

ke detector unit.

Loading...

Loading...