182

RT-SVX24Q-EN

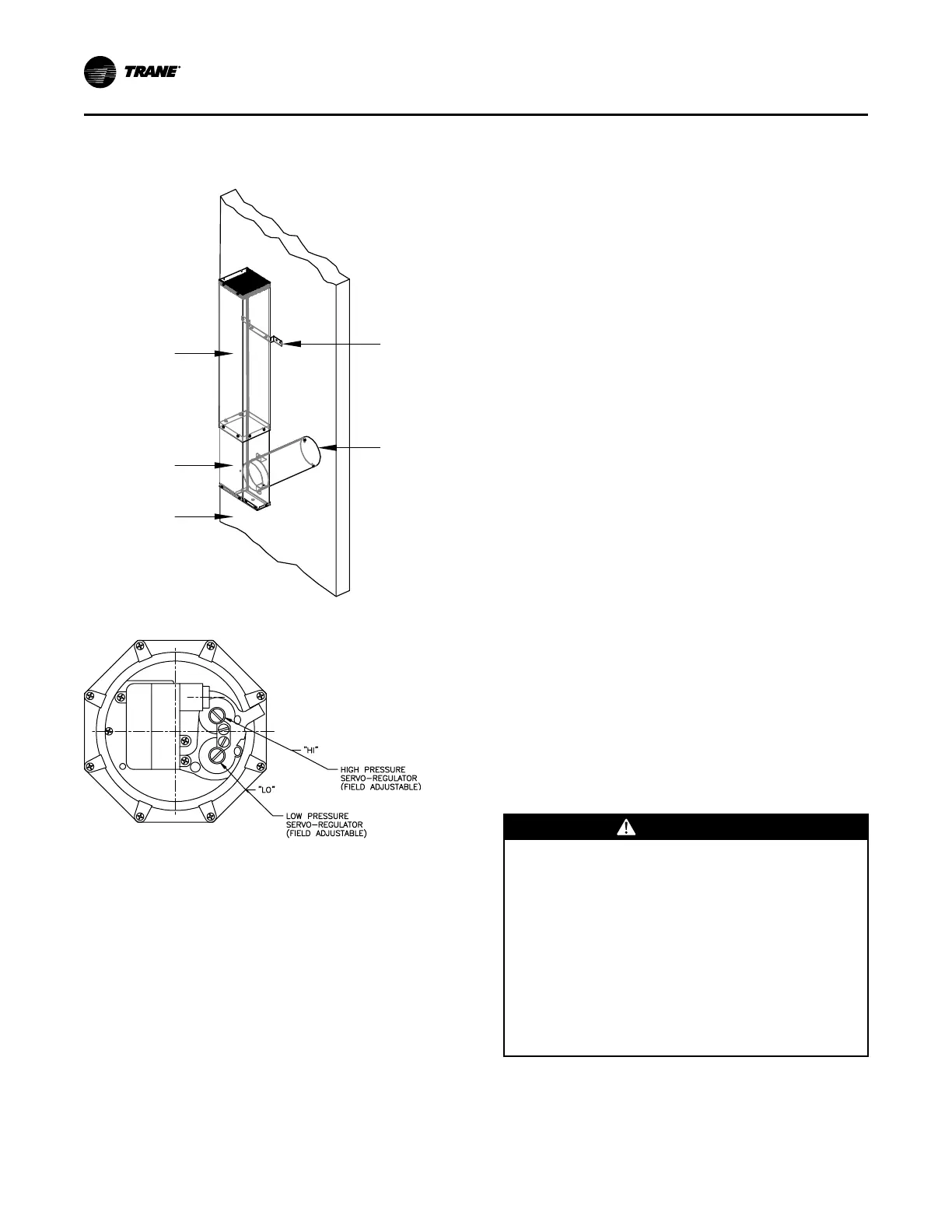

Figure 138. Flue gas carbon dioxide and oxygen

measurements - same as Figure 51, p.73 in current

catalog.

Flue

Extension

Mounting

Bracket

Flue Tube

Vent Cap

Assembly

Heat Section

Vertical Support

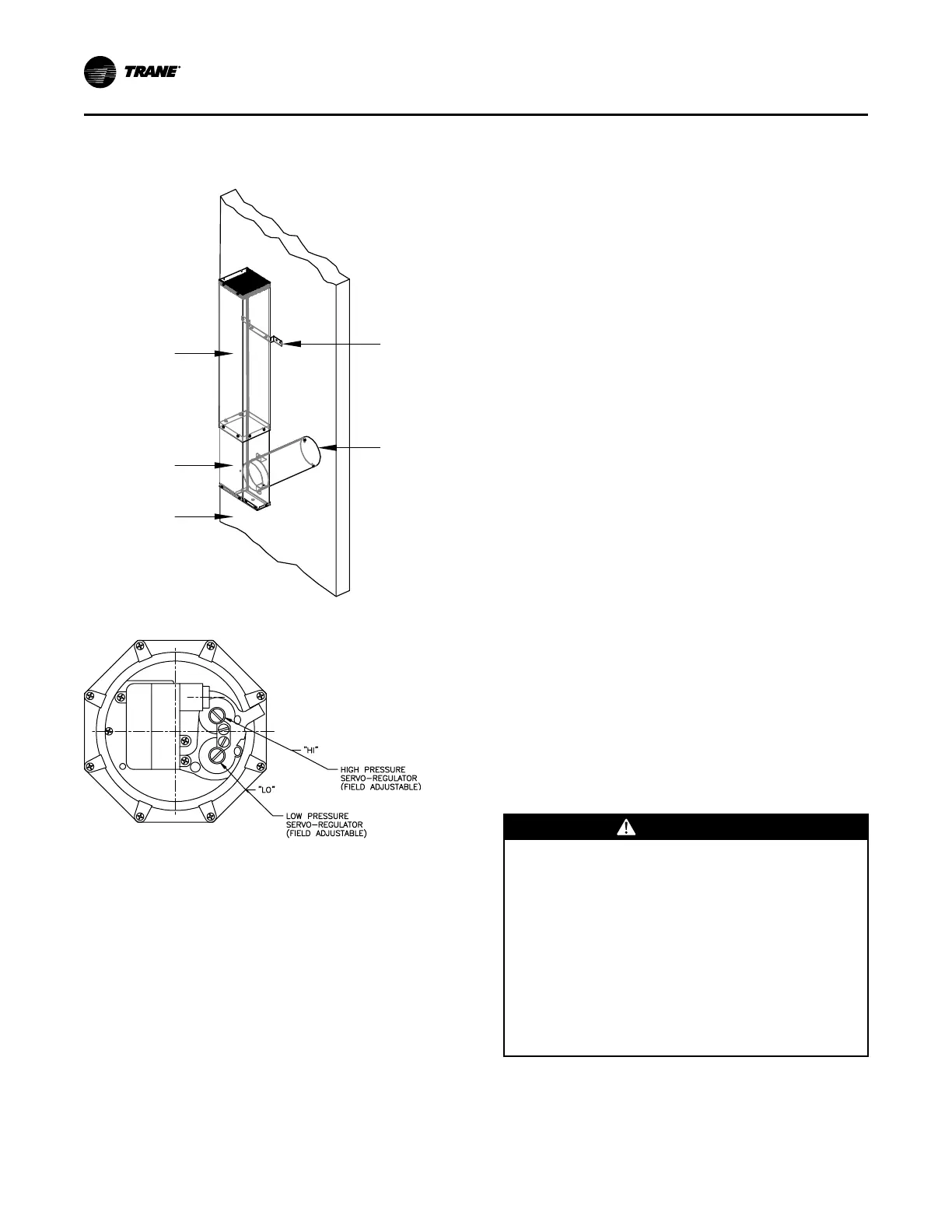

Figure 139. High/low pressure regulator

Full Modulating Gas Furnace

Full Modulating gas heaters are available for the 850,

1100, 1800, 2500 MBH heater sizes:

• The firing rate of the 850 MBH modulating heater

can vary from 10% to 100% of the 850 MBH.

• The firing rate of the 1100, 1800 and 2500 MBH can

vary from 5% to 100% of it's nameplate value.

Heat Exchanger

The heat exchanger drum, tubes and front and rear

headers are constructed from stainless steel alloys.

Unit Control

The unit is controlled by a supply air temperature

sensor located in the supply air stream for VAV units.

CV units have two sensors, one located in the supply

air stream and the zone sensor. The temperature

sensor signal is sent to the Heat module of the

IntelliPak Unit Control. The control signal from the Heat

Module signal is directly proportional to 0-10 VDC. The

higher the voltage signal, the lower the call for heat.

The 0-10 VDC signal controls the air damper actuator

which is mounted on the end of the air damper shaft.

As the actuator rotates clockwise, more combustion air

passes through the combustion air blower. In turn, the

gas butterfly valve opens more through a directly

connected linkage, resulting in a higher rate of firing.

1. Use tables in “Voltage Imbalance,” p. 105 to

program the following system components for

operation by scrolling through the Human Interface

displays :

GGaass HHeeaatt

• Supply Fan (On)

• Variable Frequency Drive (100% Output, if

applicable)

• RTM Occ/Unocc Output (Unoccupied)

• High Fire (90%)

Turn the 115 volt control circuit switch located in

the heater control panel to the “On” position.

Open the manual gas valve, located in the gas heat

section.

2. Once the configuration for the appropriate heating

system is complete, press the NEXT key until the

LCD displays the “Start test in __Sec.” screen. Press

the + key to designate the delay before the test is to

start. This service test will begin after the TEST

START key is pressed and the delay designated in

this step has elapsed. Press the ENTER key to

confirm this choice.

3. Press the TEST START key to start the test.

Remember that the delay designated in step 2 must

elapse before the system will begin to operate.

WWAARRNNIINNGG

RRoottaattiinngg CCoommppoonneennttss!!

FFaaiilluurree ttoo ddiissccoonnnneecctt ppoowweerr bbeeffoorree sseerrvviicciinngg ccoouulldd

rreessuulltt iinn rroottaattiinngg ccoommppoonneennttss ccuuttttiinngg aanndd ssllaasshhiinngg

tteecchhnniicciiaann wwhhiicchh ccoouulldd rreessuulltt iinn ddeeaatthh oorr sseerriioouuss

iinnjjuurryy..

DDuurriinngg iinnssttaallllaattiioonn,, tteessttiinngg,, sseerrvviicciinngg aanndd

ttrroouubblleesshhoooottiinngg ooff tthhiiss pprroodduucctt iitt mmaayy bbee

nneecceessssaarryy ttoo wwoorrkk wwiitthh lliivvee aanndd eexxppoosseedd rroottaattiinngg

ccoommppoonneennttss.. HHaavvee aa qquuaalliiffiieedd oorr lliicceennsseedd sseerrvviiccee

iinnddiivviidduuaall wwhhoo hhaass bbeeeenn pprrooppeerrllyy ttrraaiinneedd iinn

hhaannddlliinngg eexxppoosseedd rroottaattiinngg ccoommppoonneennttss,, ppeerrffoorrmm

tthheessee ttaasskkss..

4. Once the system has started, check the appearance

of the flame through the sight glass provided on the

front of the heat exchanger. In appearance, a

normal flame has a clearly defined shape, and is

UUnniitt SSttaarrttuupp

Loading...

Loading...