80

RT-SVX24Q-EN

Field Installed Control Wiring

The Rooftop Module (RTM) must have a mode input in

order to operate the rooftop unit. The flexibility of

having several system modes depends upon the type

of sensor and/or remote panel selected to interface

with the RTM. An overall layout of the various control

options available, with the required number of

conductors for each device, is illustrated beginning

with Figure 59, p. 86.

NNoottee:: All field wiring must conform to NEC guidelines

as well as state and local codes.

WWAARRNNIINNGG

HHaazzaarrddoouuss VVoollttaaggee!!

FFaaiilluurree ttoo ddiissccoonnnneecctt ppoowweerr bbeeffoorree sseerrvviicciinngg ccoouulldd

rreessuulltt iinn ddeeaatthh oorr sseerriioouuss iinnjjuurryy..

DDiissccoonnnneecctt aallll eelleeccttrriicc ppoowweerr,, iinncclluuddiinngg rreemmoottee

ddiissccoonnnneeccttss bbeeffoorree sseerrvviicciinngg.. FFoollllooww pprrooppeerr

lloocckkoouutt//ttaaggoouutt pprroocceedduurreess ttoo eennssuurree tthhee ppoowweerr

ccaann nnoott bbee iinnaaddvveerrtteennttllyy eenneerrggiizzeedd.. VVeerriiffyy tthhaatt nnoo

ppoowweerr iiss pprreesseenntt wwiitthh aa vvoollttmmeetteerr..

WWAARRNNIINNGG

PPrrooppeerr FFiieelldd WWiirriinngg aanndd GGrroouunnddiinngg

RReeqquuiirreedd!!

FFaaiilluurree ttoo ffoollllooww ccooddee ccoouulldd rreessuulltt iinn ddeeaatthh oorr

sseerriioouuss iinnjjuurryy..

AAllll ffiieelldd wwiirriinngg MMUUSSTT bbee ppeerrffoorrmmeedd bbyy qquuaalliiffiieedd

ppeerrssoonnnneell.. IImmpprrooppeerrllyy iinnssttaalllleedd aanndd ggrroouunnddeedd

ffiieelldd wwiirriinngg ppoosseess FFIIRREE aanndd EELLEECCTTRROOCCUUTTIIOONN

hhaazzaarrddss.. TToo aavvooiidd tthheessee hhaazzaarrddss,, yyoouu MMUUSSTT ffoollllooww

rreeqquuiirreemmeennttss ffoorr ffiieelldd wwiirriinngg iinnssttaallllaattiioonn aanndd

ggrroouunnddiinngg aass ddeessccrriibbeedd iinn NNEECC aanndd yyoouurr llooccaall//

ssttaattee//nnaattiioonnaall eelleeccttrriiccaall ccooddeess..

The various field installed control panels, sensors,

switches, and contacts discussed in this section require

both AC and DC consideration. These diagrams are

representative of standard applications and are

provided for general reference only. Always refer to the

wiring diagram that shipped with the unit for specific

electrical schematic and connection information.

Controls using 24 VAC

Before installing any connecting wiring, refer to Figure

16, p. 39 for the electrical access locations provided on

the unit, and Table 41, p. 80 for AC conductor sizing

guidelines. Then check the following:

NNOOTTIICCEE

UUssee CCooppppeerr CCoonndduuccttoorrss OOnnllyy!!

FFaaiilluurree ttoo uussee ccooppppeerr ccoonndduuccttoorrss ccoouulldd rreessuulltt iinn

eeqquuiippmmeenntt ddaammaaggee aass tthhee eeqquuiippmmeenntt wwaass nnoott

ddeessiiggnneedd oorr qquuaalliiffiieedd ttoo aacccceepptt ootthheerr ttyyppeess ooff

ccoonndduuccttoorrss..

1. Use copper conductors unless otherwise specified.

2. Ensure that the AC control wiring between the

controls and the unit's termination point does not

exceed three (3) ohms/conductor for the length of

the run.

NNoottee:: Resistance in excess of 3 ohms per conductor

may cause component failure due to insufficient

AC voltage supply.

3. Make sure to check all loads and conductors for

grounds, shorts, and mis-wiring.

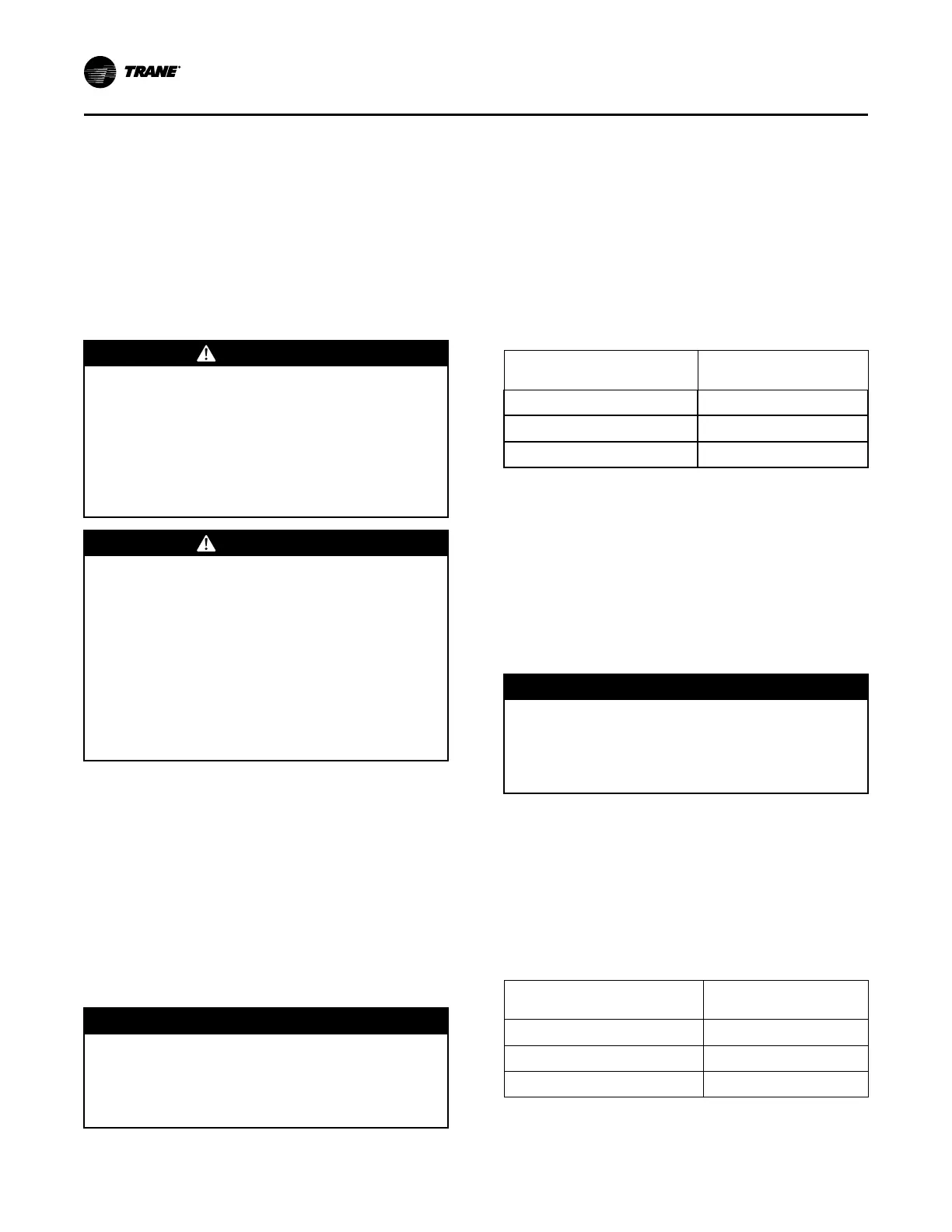

Table 41. AC conductors

Distance from Unit to

Control

Recommended Wire

Size

000-460 feet

18 gauge

461-732 feet

16 gauge

733-1000 feet

14 gauge

4. Do not run the AC low voltage wiring in the same

conduit with the high voltage power wiring.

Controls using DC Analog Input/Outputs

Before installing any connecting wiring between the

unit and components utilizing a DC analog input\output

signal, refer to the appropriate illustration in Figure 16,

p. 39 for the electrical access locations provided on the

unit and Table 42, p. 80 for conductor sizing guidelines.

Then check the following:

NNOOTTIICCEE

UUssee CCooppppeerr CCoonndduuccttoorrss OOnnllyy!!

FFaaiilluurree ttoo uussee ccooppppeerr ccoonndduuccttoorrss ccoouulldd rreessuulltt iinn

eeqquuiippmmeenntt ddaammaaggee aass tthhee eeqquuiippmmeenntt wwaass nnoott

ddeessiiggnneedd oorr qquuaalliiffiieedd ttoo aacccceepptt ootthheerr ttyyppeess ooff

ccoonndduuccttoorrss..

1. Use standard copper conductor thermostat wire

unless otherwise specified.

2. Ensure that the wiring between the controls and the

unit termination point does not exceed two and a

half (2.5) ohms/conductor for the length of the run.

NNoottee:: Resistance in excess of 2.5 ohms per conductor

can cause deviations in the accuracy of the

controls.

Table 42. DC conductors

Distance from Unit to

Control

Recommended Wire

Size

000-150 feet

22 gauge

151- 240 feet

20 gauge

241- 385 feet

18 gauge

IInnssttaallllaattiioonn

Loading...

Loading...