RTAA-SVX01A-EN 47

Installation — Remote Evaporator

Oil Charge Determination

The unit is factory charged with the amount of oil required by the system,

without the field-installed piping. The amount of additional oil required is

dependent upon the amount of refrigerant that is added to the system for the

field-installed piping.

Use the following formula to calculate the amount of oil to be added:

Pints of Oil (Trane Oil-31) =

lbs of refrigerant added for field-installed piping

100

From the example above, in which the weight of the additional refrigerant

added for the field-installed piping was 34.0 lbs (30.6 + 3.4), the amount of oil

to be added equals 0.34 pints (34.0/100) per circuit.

Example: Refrigerant Charge Computation

Determine the approximate amount of charge required for an RTAA 100 ton

unit with a remote evaporator that is located 75 feet away (i.e the actual

length of field-installed pipe is 75 feet for each suction line and liquid line).

Assume that the suction lines have been previously determined to be in.,

O.D. and the liquid lines are in. 1-1/8 O.D.

Relief Valve Venting

All relief valve venting is the responsibility of the installing contractor.

The remote evaporators on chillers sold with this option utilize relief valves

installed in each circuit of the evaporator head. There is one relief valve per

circuit, and they must be vented to the outside of the building.

1. From Table 2g for a 50 ton

circuit requires:

= 73 lbs. R-22

2. From Table 2h for a 2-518

inch OD suction line:

75 feet x 4.5 feet = 3.4 lbs. R-22

3. From Table 2h for a 1 118

inch OD liquid line:

75 feet x 40.8 feet = 30.6 Ibs. R-22

4. Total R-22 charge per circuit: Sum results of steps

1,2, and 3

= 107 Ibs. R-22 per circuit

5. Total R-22 charge per machine: 2 circuits x 107 Ibs. = 214 Ibs. R-22 per machine

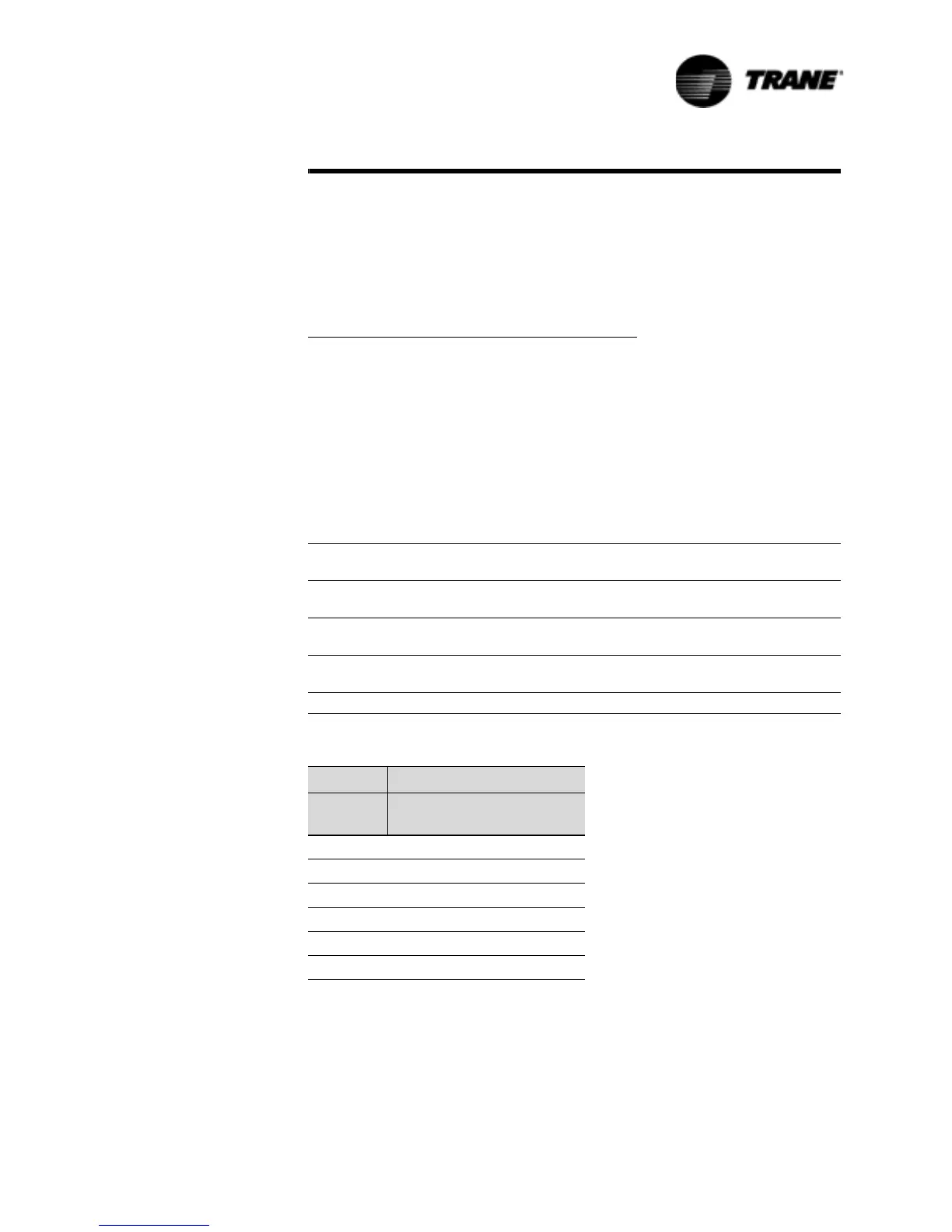

Table 9 Field-Installed Piping Charge

Lbs. R-22 per 100 ft.

Pipe O.D.

(inches) Suction Line Liquid Line

1-1/8 0.78 40.8

1-3/8 1.2 62.2

1-5/8 1.7 88

2-1/8 2.9 153.1

2-5/8 4.5 236.1

3-1/8 6.4 —

Loading...

Loading...