RTAA-SVX01A-EN 51

Installation — Electrical

Installer-Supplied Components

All wiring must comply with local codes and the National Electrical Code. The

installing (or electrical) contractor must provide and install the system inter-

connecting wiring, as well as the power supply wiring. It must be properly

sized and equipped with the appropriate fused-disconnect switches. The type

and installation location(s) of the fused-disconnects must comply with all

applicable codes.

The installer must provide the following components if not ordered with the

unit:

• Power supply wiring (in conduit) for all field-wired connections.

• All control (interconnecting) wiring (in conduit) for field supplied devices.

• Fused-disconnect switches.

Remote Evaporator Only:

• Control wiring between the outdoor unit and the evaporator terminal box.

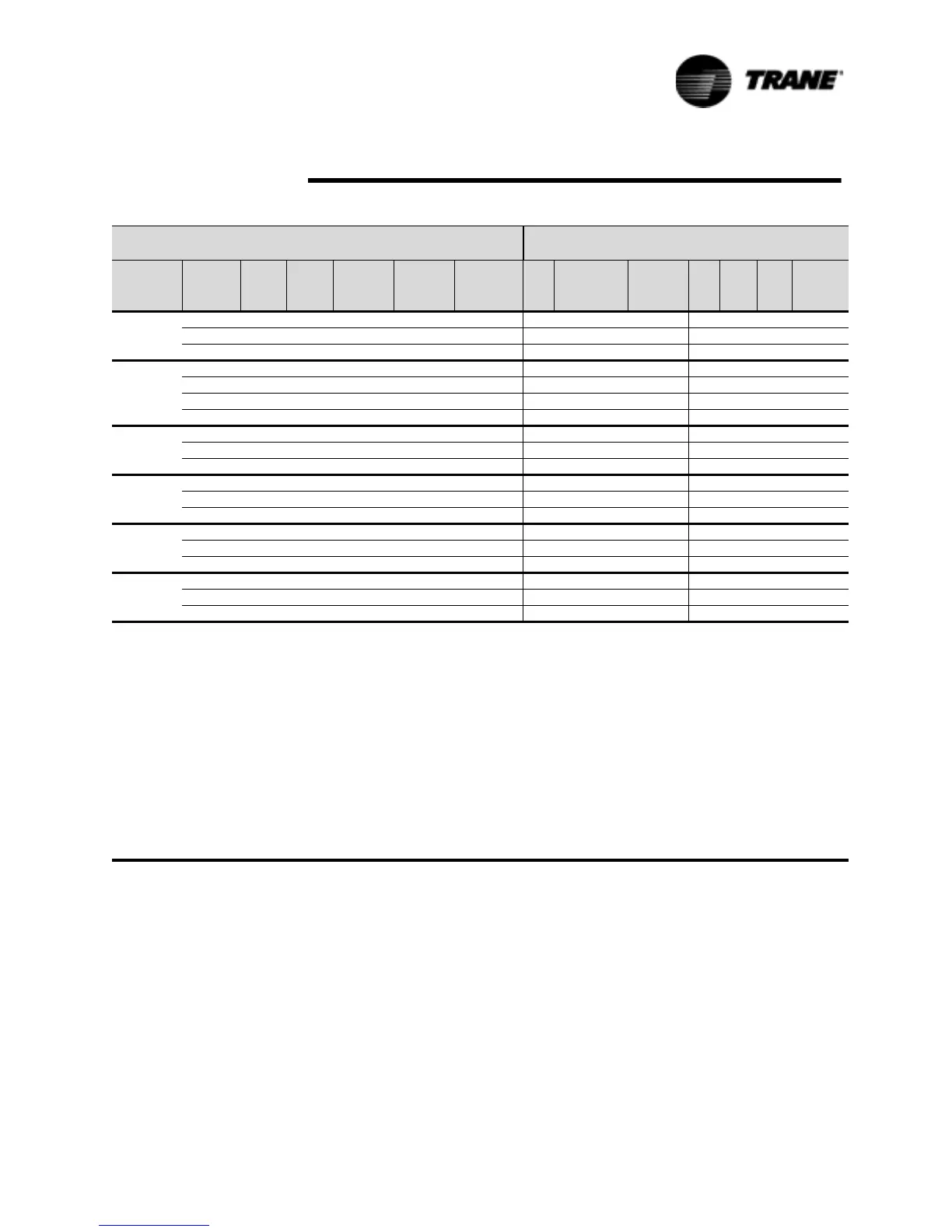

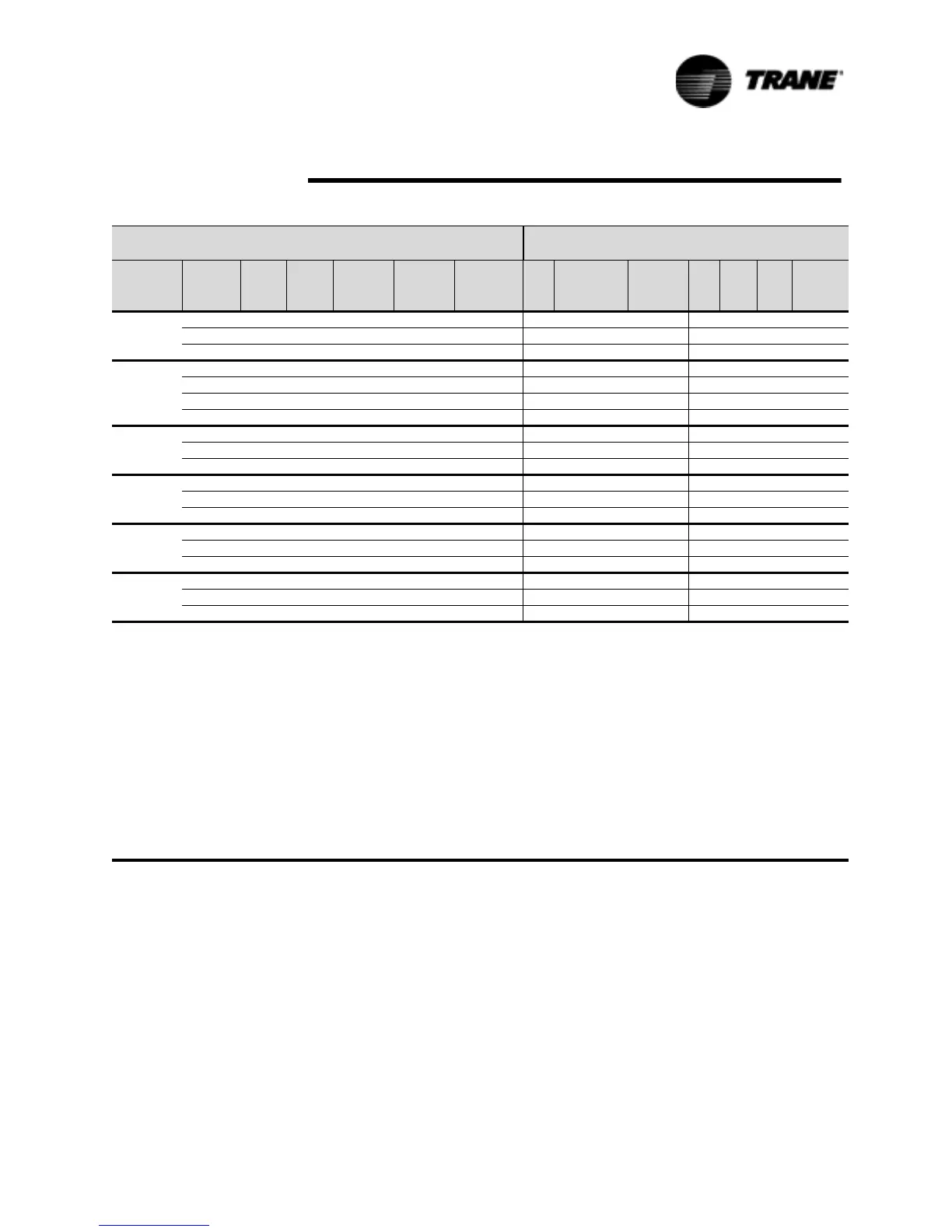

Table 11 Electrical Data - Pump Package Option

Unit Wiring

Motor Data

Unit Size

Rotated

Voltage

Pump

HP

Pump

FLA MCA (2) MOP (1)

Rec Time

Delay or

RDE (3) Qty

Comp(Ea)

RLA (4) LRA (7) Qty

Fans

(Ea)

KW FLA

Control

KW (6)

RTAA 70

460/60 2 3.1 136 175 150 2 50/50 330/330 8 1.0 2.5 0.75

460/60 3 4.1 137 175 150 2 50/50 330/330 8 1.0 2.5 0.75

460/60 5 6.6 139 175 175 2 50/50 330/330 8 1.0 2.5 0.75

RTAA 80 460/60 2 3.1 163 200 200 2 62/62 380/380 8 1.0 2.5 0.75

460/60 3 4.1 164 225 200 2 62/62 380/380 8 1.0 2.5 0.75

460/60 5 6.6 166 225 200 2 62/62 380/380 8 1.0 2.5 0.75

460/60 7.5 10.3 170 225 200 2 62/62 380/380 8 1.0 2.5 0.75

RTAA 90

460/60 3 4.1 194 250 225 2 84/62 410/380 9 1.0 2.5 0.75

460/60 5 6.6 196 250 225 2 84/62 410/380 9 1.0 2.5 0.75

460/60 7.5 10.3 200 250 225 2 84/62 410/380 9 1.0 2.5 0.75

RTAA 100

460/60 3 4.1 218 300 250 2 84/84 410/410 10 1.0 2.5 0.75

460/60 5 6.6 221 300 250 2 84/84 410/410 10 1.0 2.5 0.75

460/60 7.5 10.3 224 300 350 2 84/84 410/410 10 1.0 2.5 0.75

RTAA 110

460/60 3 4.1 239 300 300 2 101/84 522/410 10 1.0 2.5 0.75

460/60 5 6.6 242 300 300 2 101/84 522/410 10 1.0 2.5 0.75

460/60 7.5 10.3 246 300 300 2 101/84 522/410 10 1.0 2.5 0.75

RTAA 125

460/60 3 4.1 256 350 300 2 101/101 522/522 10 1.0 2.5 0.75

460/60 5 6.6 259 350 300 2 101/101 522/522 10 1.0 2.5 0.75

460/60 7.5 10.3 263 350 300 2 101/101 522/522 10 1.0 2.5 0.75

(1) MOP - Maximum Overcurrent Protection - may be either type breaker (UL/CSA) or with circuit breakers (CSA only). MOP = 225 percent of the largest

compressor RLA plus 100 percent of the second compressor plus the sum of the condenser fans FLAs per NEC 440-22.

(2) MCA - Minimum Circuit Ampacity - 125 percent of largest compressor RLA plus 100 percent of second compressor plus the sum of the condenser

fans FLAs per NEC 440-33.

(3) RECOMMENDED TIME DELAY OR DUAL ELEMENT (RDE) FUSE SIZE: 150 percent of the largest compressor RLA plus 100 percent of the

second compressor RLA and the sum the condenser fan FLAs.

(4) RLA -Rated Load Amps -rated in accordance with UL Standard 465.

(5) Local codes may take precedence.

(6) Control kw includes operational controls only. Does not include heat tapes.

(7) LRA - Locked Rotor Amps -based on full winding start units.

(8) VOLTAGE UTILIZATION RANGE:

Rated Voltage Utilization Range

200/60 180-220

230/60 208-254

460/60 414-506

575/60 516-633

400/50 340-460

(9) 60 HZ UNITS - A 115/60/1, 15 amp. customer provided power connection is required to power the evaporator heat tape 420 watts

(10) 50 HZ UNITS - A separate 220/50/1 15 amp. customer provided power connection is needed to power evaporator heat tape 420 watts @ 220 volts.

Loading...

Loading...