Technical Section

Part Two

Technical Section

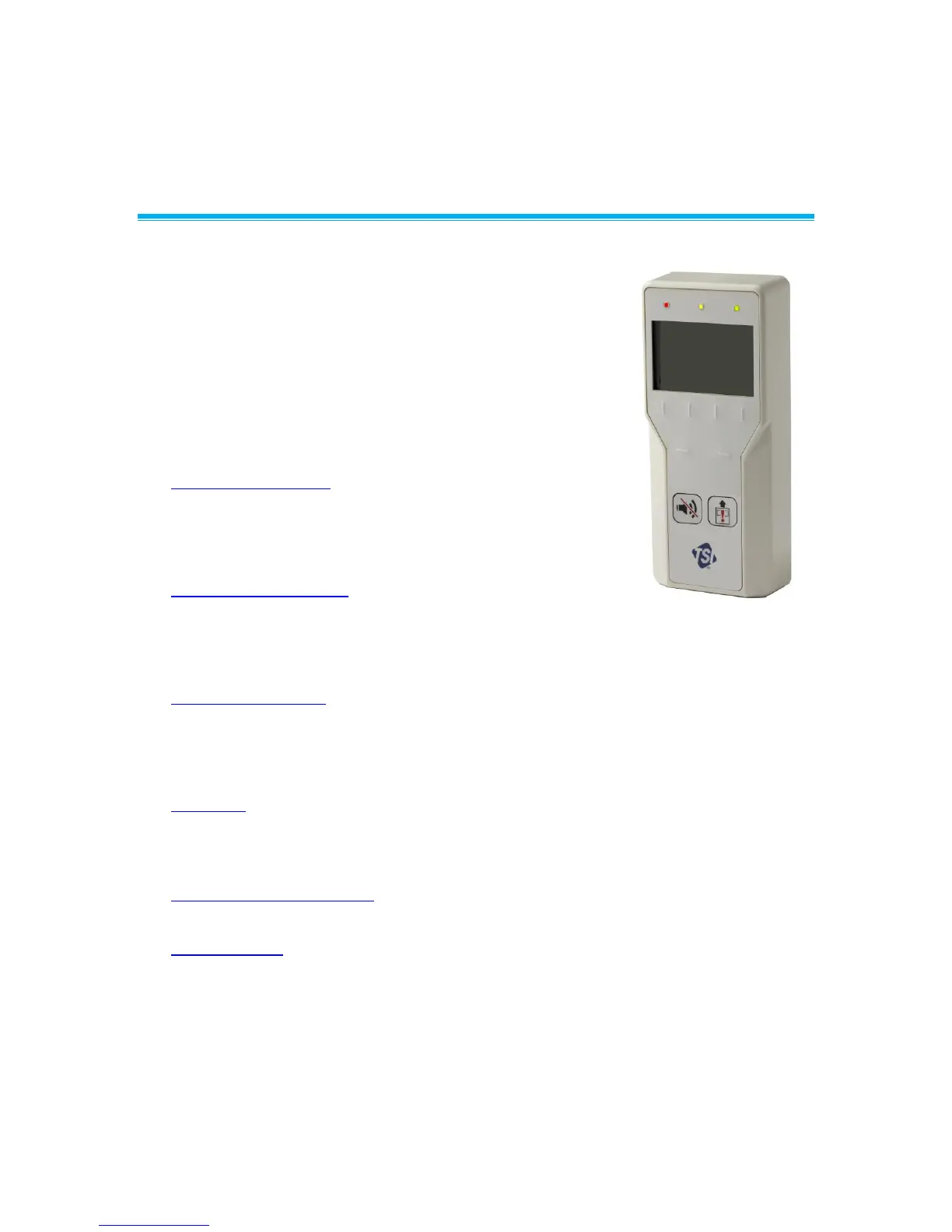

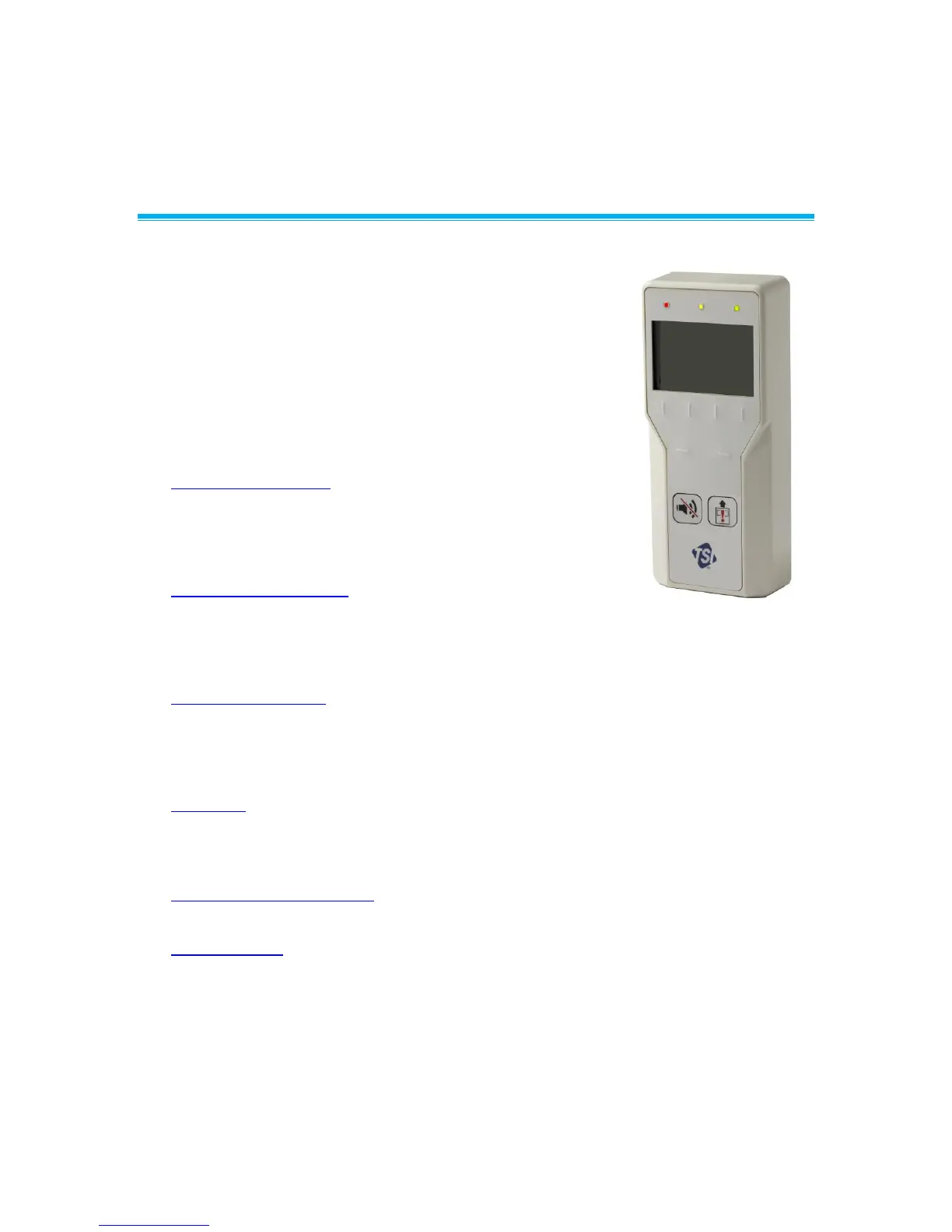

The Fume Hood Controller is ready to use after being properly

installed and calibrated. The calibration procedure should take

less than 15 minutes. Figure 2 shows the Digital Interface Module

(DIM) which is programmed with a default configuration that can

be easily modified to fit your application.

The technical section is separated into six parts that cover all

aspects of the unit. Each section is written as independently as

possible to minimize flipping back and forth through the manual

for an answer.

The Software Programming section explains the programming

keys on the DIM. In addition, the programming sequence is

described, which is the same regardless of the menu item being

changed. At the end of this section is an example of how to

program the DIM.

The Hardware Configurations section covers the different ways

the DIM can be configured to accommodate the hardware and

sequence of operation that is required. This section explains how

to compare the installed hardware to the necessary settings that

are needed.

The Menu and Menu Items section lists all of the software items available to program and

change. The items are grouped by menu which means all set points are in one menu, control

signal items in another, etc. The menu items and all related information is provided including;

programming name, description of menu item, range of programmable values, and how the unit

shipped from the factory (default value).

The Calibration section describes the required procedure to calibrate the controller. This section

explains how to compare the controller’s velocity reading to a portable thermal anemometer and

then adjust the zero and span to establish an accurate calibration. This section also describes

how to zero a TSI flow station transducer (if installed).

The Maintenance and Repair Part section covers all routine maintenance of equipment, along

with a list of repair parts.

The Troubleshooting section is split into two areas: mechanical operation of the unit and system

performance. Many external variables will affect how the unit functions so it is critical to first

determine if the system is having mechanical problems—i.e., no display on unit, alarms do not

function, damper does not modulate, etc. If no mechanical problems exist, look for performance

problems (i.e., does not seem to read correctly, display fluctuates, etc.). The first step is to

determine that the system is mechanically operating correctly, followed by modifying the

configuration to eliminate the performance problems.

Loading...

Loading...