Installation, Operating & Maintenance Instructions

Series 650, DN 100 – 250 (I.D. 4" - 10")

VAT Vakuumventile AG, CH-9469 Haag, Switzerland

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch www.vatvalve.com

258550EE

2007-05-11

21/51

3.6 Setup procedure

To enable this valve for pressure control setup steps 1 to 5 must

be performed.

In case position control is required only it’s sufficient to perform steps 1 to 3.

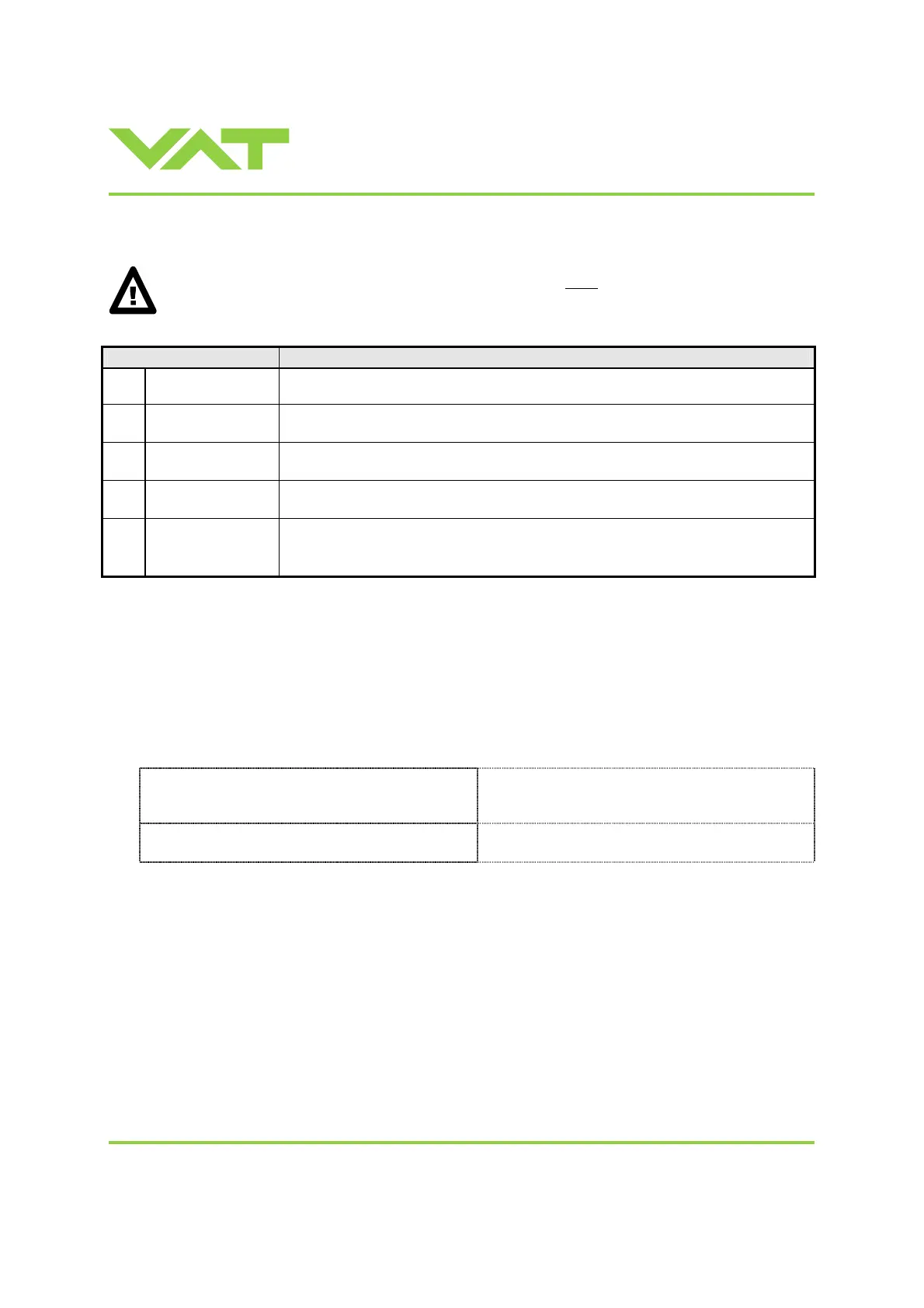

Setup step Description

1

Power up

Turn on external + 24VDC power supply (and external ±15 VDC for sensor power

supply if required). Refer to chapter «3.3 Behavior during power up» for details.

2

Interface

configuration

Functionality of multi purpose digital inputs and outputs must be configured.

Refer to chapter «3.6.1 Interface configuration» for details.

3

Valve and sensor

configuration

Basic configurations of the valve must be adapted according to application needs.

Refer to chapter «3.6.2 Valve and sensor configuration» for details.

4

ZERO

Compensation of the sensor offset voltage.

Refer to chapter «3.6.3 ZERO» for details.

5

LEARN

Determination of the vacuum system characteristic to accommodate the PID

controller. Refer to chapter «3.6.4 LEARN» for details.

Note: Without LEARN the valve is not able to run pressure control

3.6.1 Interface configuration

Interface configuration must be adapted according to application needs.

• Functionality of digital inputs CLOSE VALVE and OPEN VALVE must be selected.

These may be configured as ‘not inverted‘ or ‘inverted‘. Default is ‘not inverted‘.

• LEARN range configuration for remote operation must be selected.

This may either be ‘full range’ or pressure limit according of analog SETPOINT input. Default is ‘full range‘.

Local operation:

(‘Control View’ resp. ‘Control Performance Analyzer’)

Remote operation:

Do configuration in menu ‘Setup / Interface’.

Note: It’s not possible to do interface configuration

via remote operation.

Loading...

Loading...