Tighten hose clip on outer joint

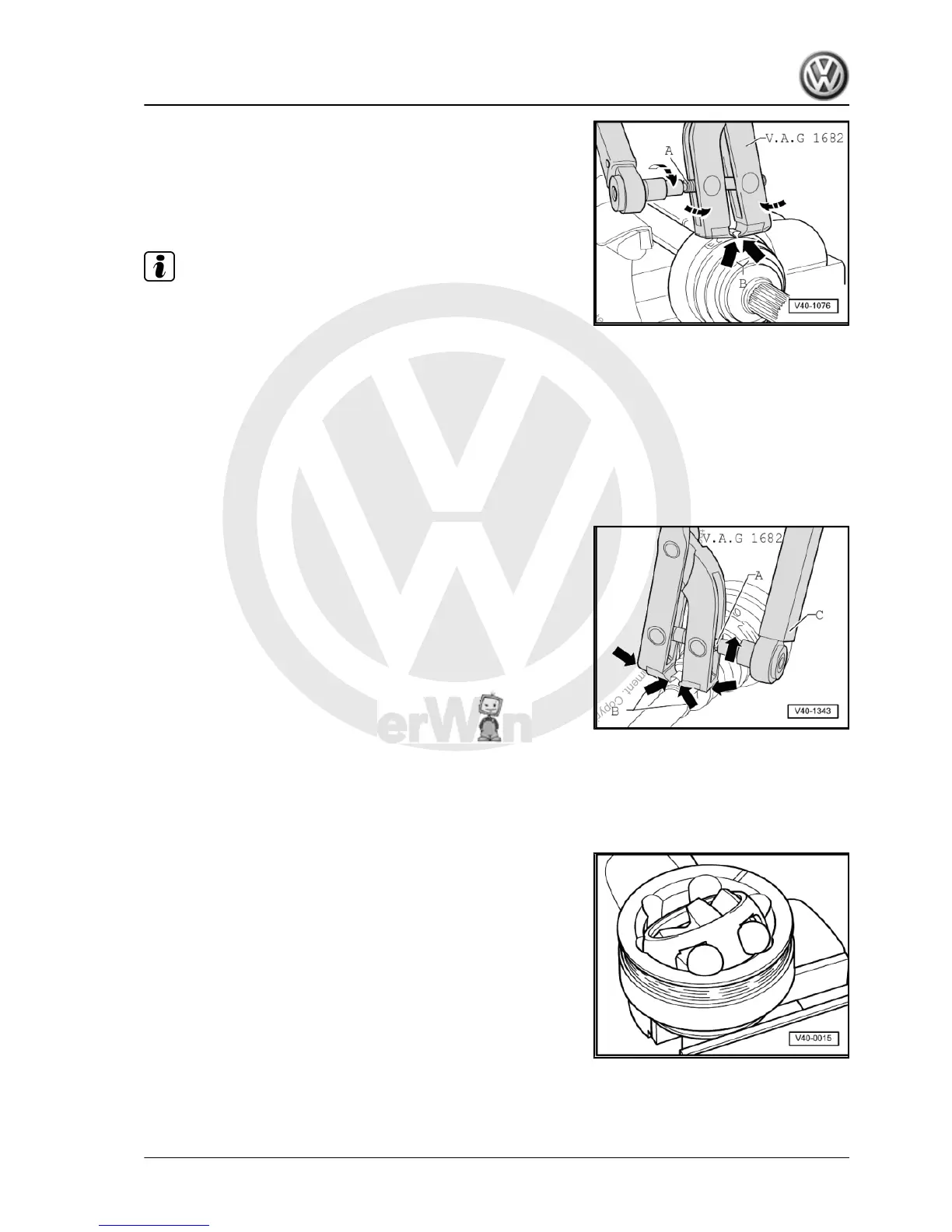

– Apply special pliers -V.A.G 1682- as shown in diagram. En‐

sure that the jaws of the pliers seat in the ends of the hose clip

-arrows B-.

– Tighten hose clip by turning spindle with a torque wrench (do

not cant pliers).

Note

♦

Because a stainless steel hose clip is required due to the hard

material of the joint boot (compared to rubber), it is possible to

tighten the hose clip only with special pliers -V.A.G 1682- .

♦

Specified torque: 25 Nm.

♦

Use torque wrench -C- with adjustment range 5 ... 50 Nm, (e.g.

torque wrench -V.A.G 1331- ).

♦

Make sure thread of spindle -A- on pliers moves freely. Lubri‐

cate with MoS2 grease if necessary.

♦

If the thread is tight (e.g. due to dirt), the required clamping

force for the clip will not be attained although the correct torque

is applied.

Tightening hose clip on small diameter

8.2 Checking outer constant velocity joint

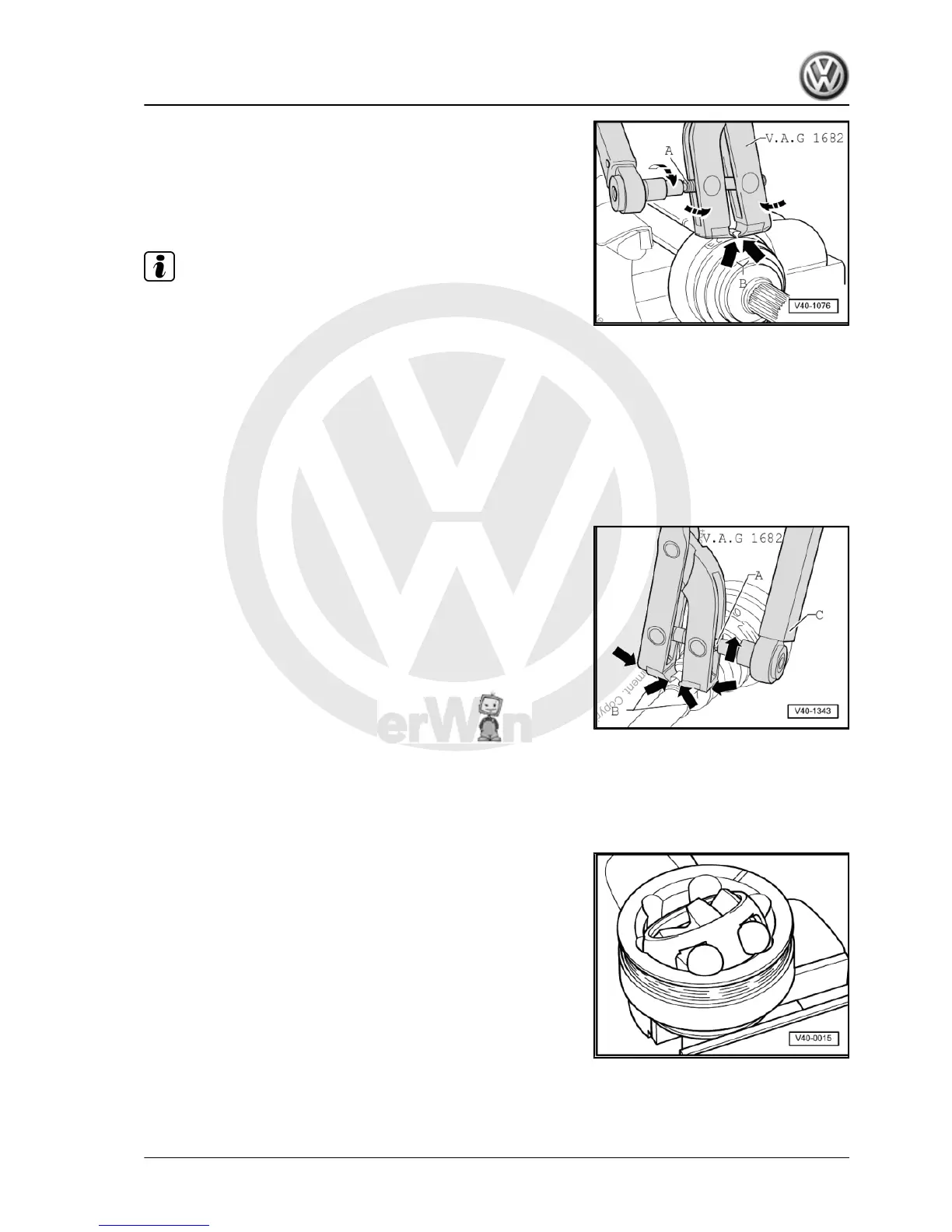

The joint is to be dismantled to renew the grease if it is heavily

soiled, or to check the running surfaces of the balls for wear and

damage.

Removing

– Before dismantling, mark position of ball hub in relation to ball

cage and joint body with an electric scriber or oil stone.

– Swing ball hub and ball cage.

– Remove balls one at a time.

Golf 2004 ➤ , Golf Plus 2005 ➤

Running gear, axles, steering - Edition 08.2009

8. Assembly overview - drive shaft with VL90 or VL100 constant velocity joint 103

Loading...

Loading...