4.4 Removing tyre from wheel

Caution

♦ Comply with the notes on safety and conditions

⇒ page 290

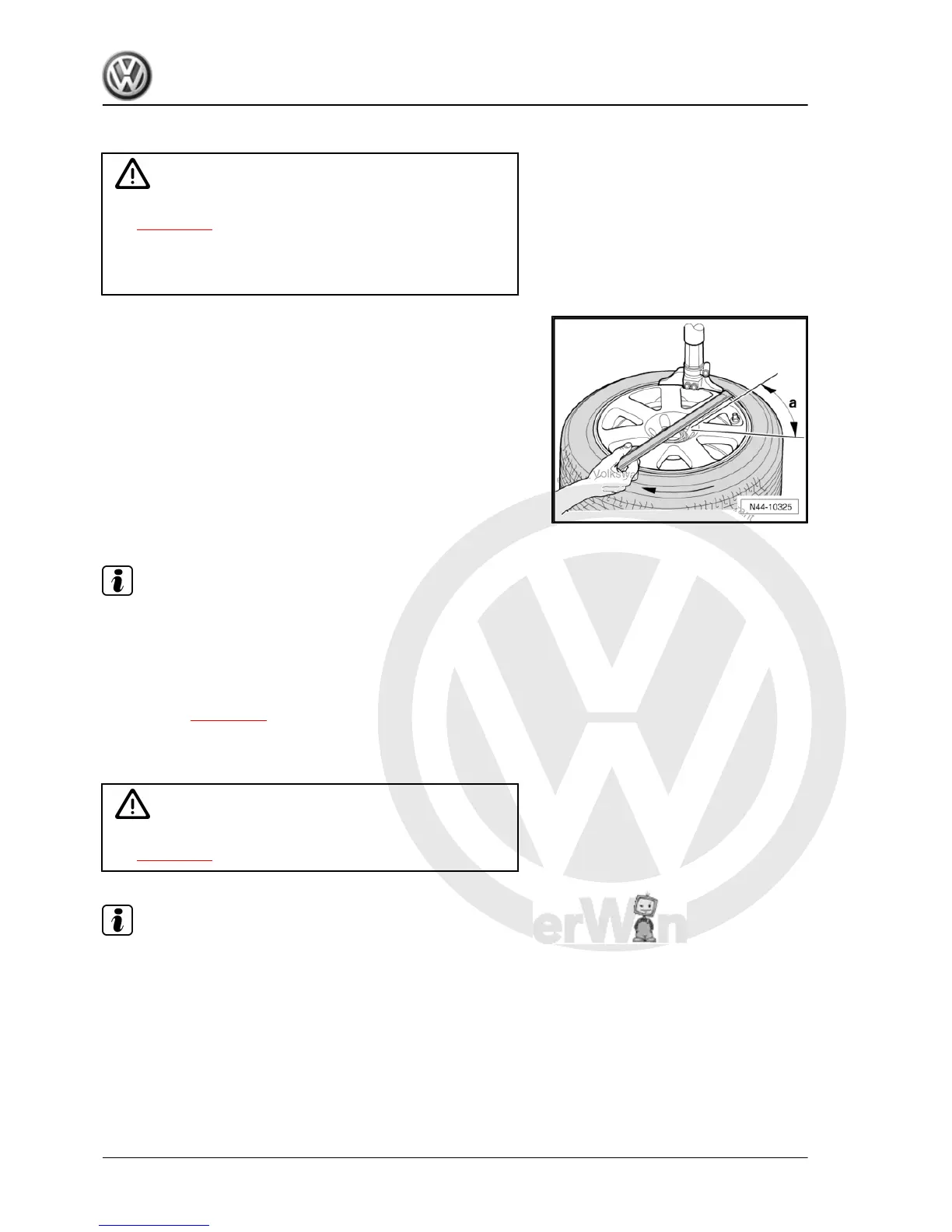

♦ The assembly head must never be within area -a- of tyre

valve/tyre pressure sensor, or the assembly head will

damage the tyre pressure sensor .

Fitting tyre

– Turn wheel on tyre fitting unit so that tyre valve/ tyre pressure

sensor is in front of the assembly head.

– Position assembly head near tyre valve/ tyre pressure sensor

so that an assembly lever can be inserted approx. 30° next to

the tyre valve/ tyre pressure sensor .

– Now lever tyre bead over assembly finger on assembly head

using assembly lever then remove assembly lever.

– Run tyre fitting machine clockwise until upper bead lies com‐

pletely above wheel rim flange.

– Turn wheel on tyre fitting unit so that tyre valve/ tyre pressure

sensor is in front of the assembly head.

Note

♦

Check that the tyre pressure sensor is not loose or damaged.

If the screwed connection is loose, replace the union nut, the

valve insert, the seal, the sealing washer and the valve cap

with new parts from the repair set ⇒ Electronic parts catalogue

“ETKA” .

♦

If the tyre pressure sensor is damaged, then replace the com‐

plete item ⇒ page 304 .

4.5 Fitting tyre to wheel rim

Caution

♦ Comply with the notes on safety and conditions

⇒ page 290

Note

When a tyre is changed, it is recommended also to change the

set of seals for the tyre pressure sensor.

– Coat wheel rim flanges, tyre beads and inside of upper tyre

bead generously with tyre assembly paste.

– First fit inner side of tyre.

Golf 2004 ➤ , Golf Plus 2005 ➤

Running gear, axles, steering - Edition 08.2009

292 Rep. Gr.44 - Wheels, tyres, vehicle geometry