6 Removing and installing drive shafts

Removing and installing drive shaft with constant velocity joint

⇒ page 79 .

Removing and installing left drive shaft with (push-on) constant

velocity slip joint ⇒ page 81 .

Removing and installing right drive shaft with (push-on) constant

velocity slip joint ⇒ page 85 .

Removing and installing drive shafts with triple roller joint

AAR2600i ⇒ page 88 .

Removing and installing drive shafts with triple roller joint

AAR3300i ⇒ page 90 .

Removing and installing intermediate shaft ⇒ page 92 .

WARNING

When removing and installing drive shafts, do not allow them

to hang free and stop against joints due to over bending.

6.1 Loosening and tightening drive shaft

hexagon bolt

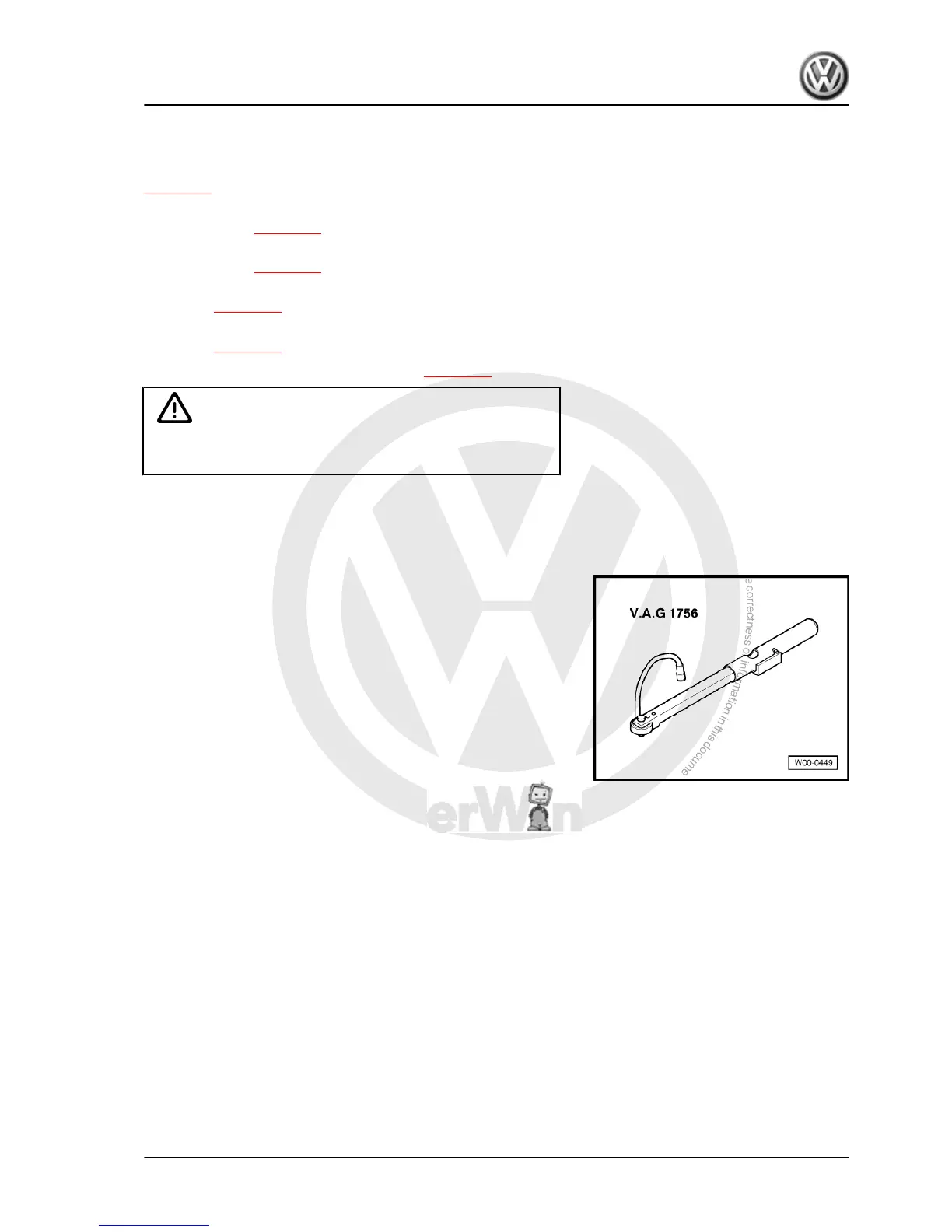

Special tools and workshop equipment required

♦ Torque/angle wrench -V.A.G 1756-

Wheel bearings must not be subjected to load after bolt securing

drive shaft to wheel hub has been loosened.

If wheel bearings are loaded with weight of vehicle, bearing will

be damaged. This reduces the service life of the wheel bearing.

It is therefore important to note the following:

♦ Procedure for loosening hexagon bolt.

Do not attempt to move the vehicle without the drive shafts fitted

as this would result in wheel bearing damage. If the vehicle does

have to be moved, always note the following points:

– Fit an outer joint in place of drive shaft.

– Tighten outer joint to 120 Nm.

Loosening hexagon bolt

– For vehicles which are still standing on their wheels, loosen

the hexagon bolt a maximum of 90°, as the wheel bearing will

otherwise be damaged.

– Raise vehicle so that wheels are off the ground.

– Have second mechanic apply brakes.

Golf 2004 ➤ , Golf Plus 2005 ➤

Running gear, axles, steering - Edition 08.2009

6. Removing and installing drive shafts 77

Loading...

Loading...