Valve Seats and Valve, Grinding

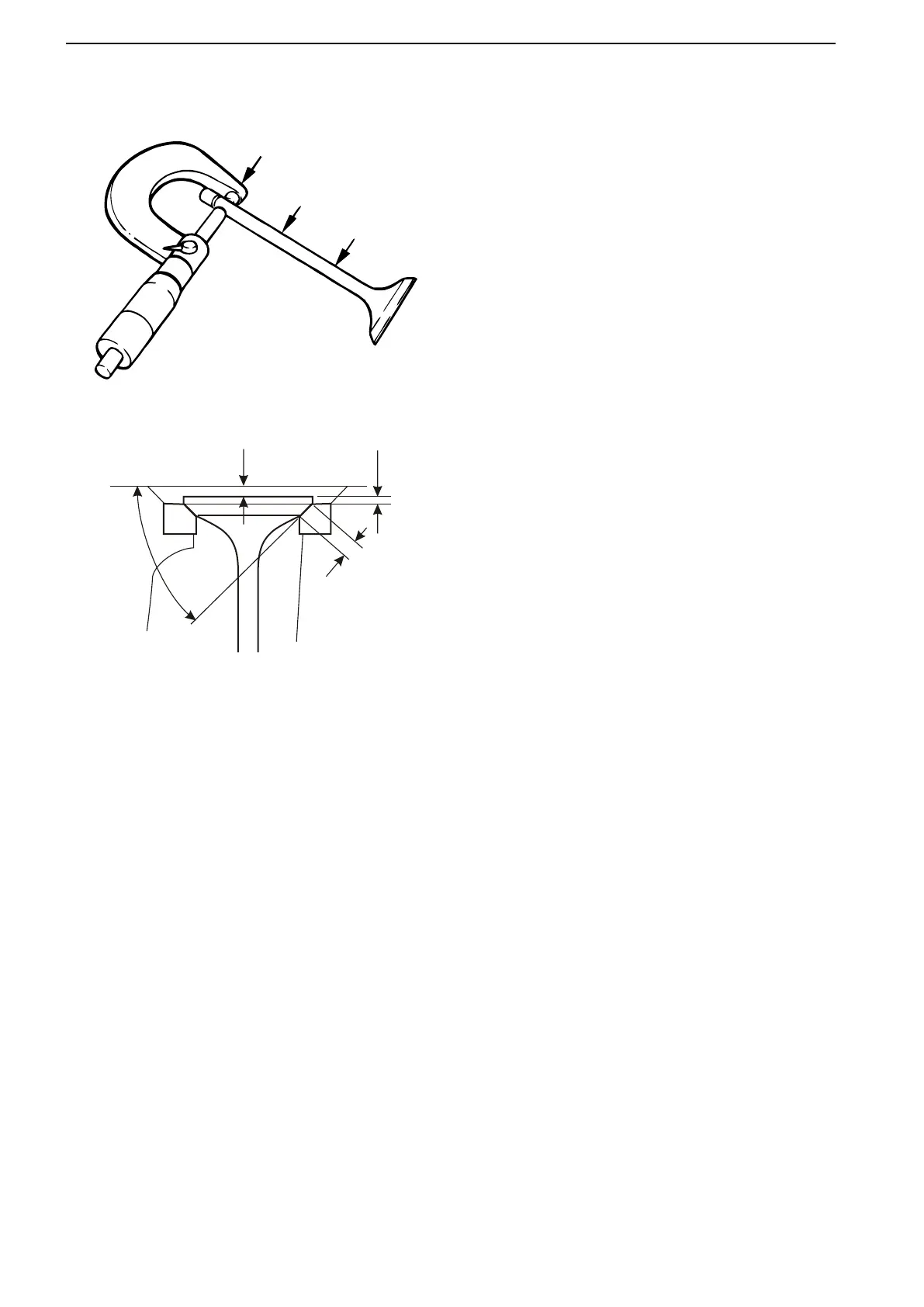

1 Check valve

stem wear. Measure the diameter with

a micrometer at points I, II and III.

Diameter, min. inlet: 6.89 mm (0.271")

Diameter, min. exhaust: 6.84 mm (0.269")

2 Grind the valves in a valve grinding machine.

Grind the sealing surface as little as possible, but

just enough to “clean” it up. If the valve disc edge

(A) after grinding is less than 0.5 mm (0.020"),

scrap the valve. Equally, any valve with a bent valve

stem must be scrapped.

3 Check valve guide wear (please refer to Valve

Guides, Inspection page 73) before the valve seats

are machined.

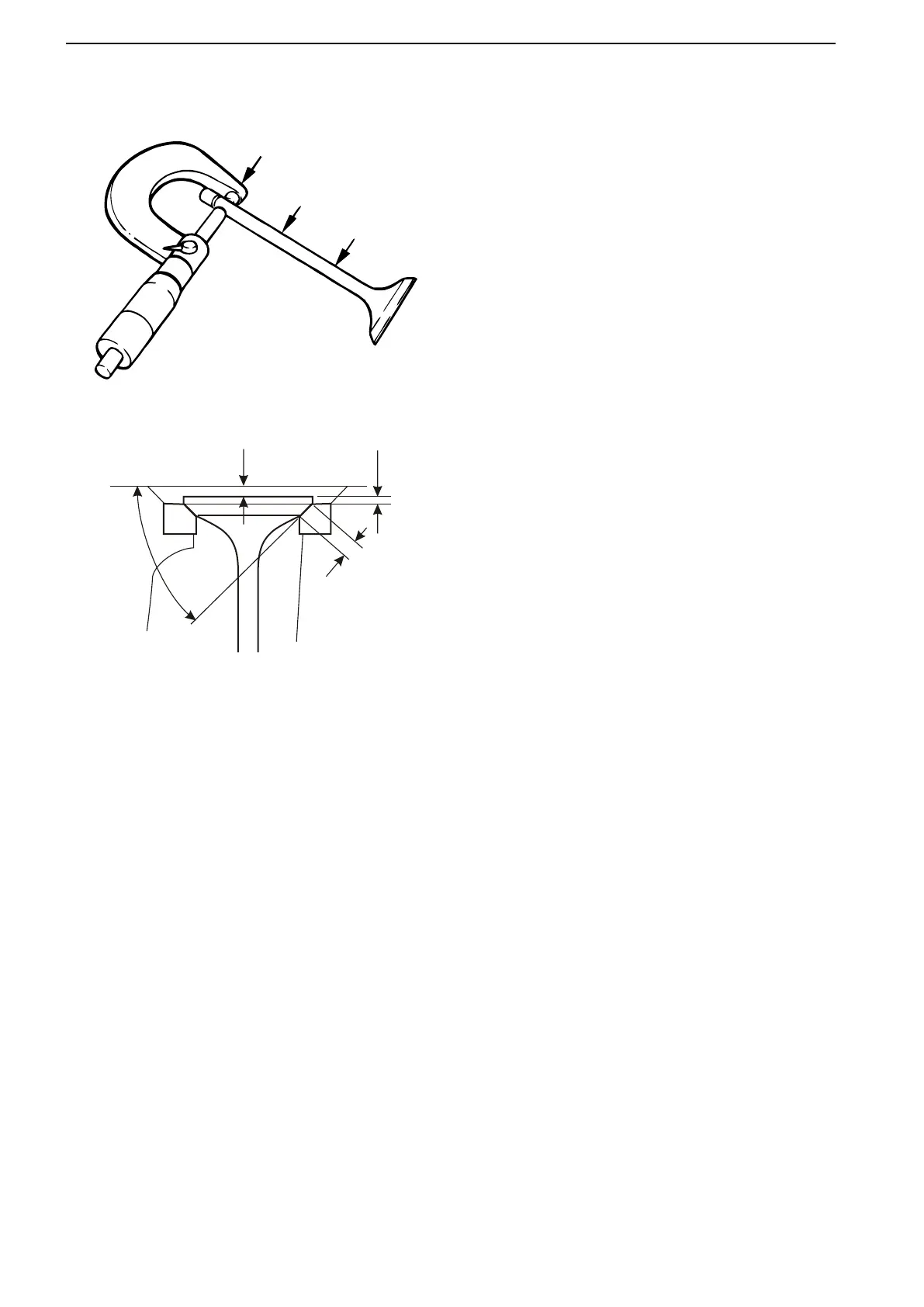

4 Mill the valve guides. When machined, only remove

enough material to give the valve seat the correct

shape and a good mating surface.

NOTICE! Do not grind so much that the valve depth

exceeds the permissible value. Please refer to

Valve Seat, Change page 75.

Mill new seats down so far that the distance

between the cylinder head plane and the valve disc

surface (B) is between 0.65-0.95 mm (0.026–

0.037") for the inlet and 0.85-1.15 mm (0.020–

0.045") for the exhaust.

The mating face (C) must be 45 degrees and the

contact surface (D) must be 1.70-2.10 mm (0.067–

0.083").

5 Grind the valves in with grinding paste, and check

contact with marker dye.

21-4 Valve Mechanism

74 47701798 05-2013 © AB VOLVO PENTA

Loading...

Loading...