WM 90 Repair Reassembly Procedures

wc_tx000389gb.fm 57

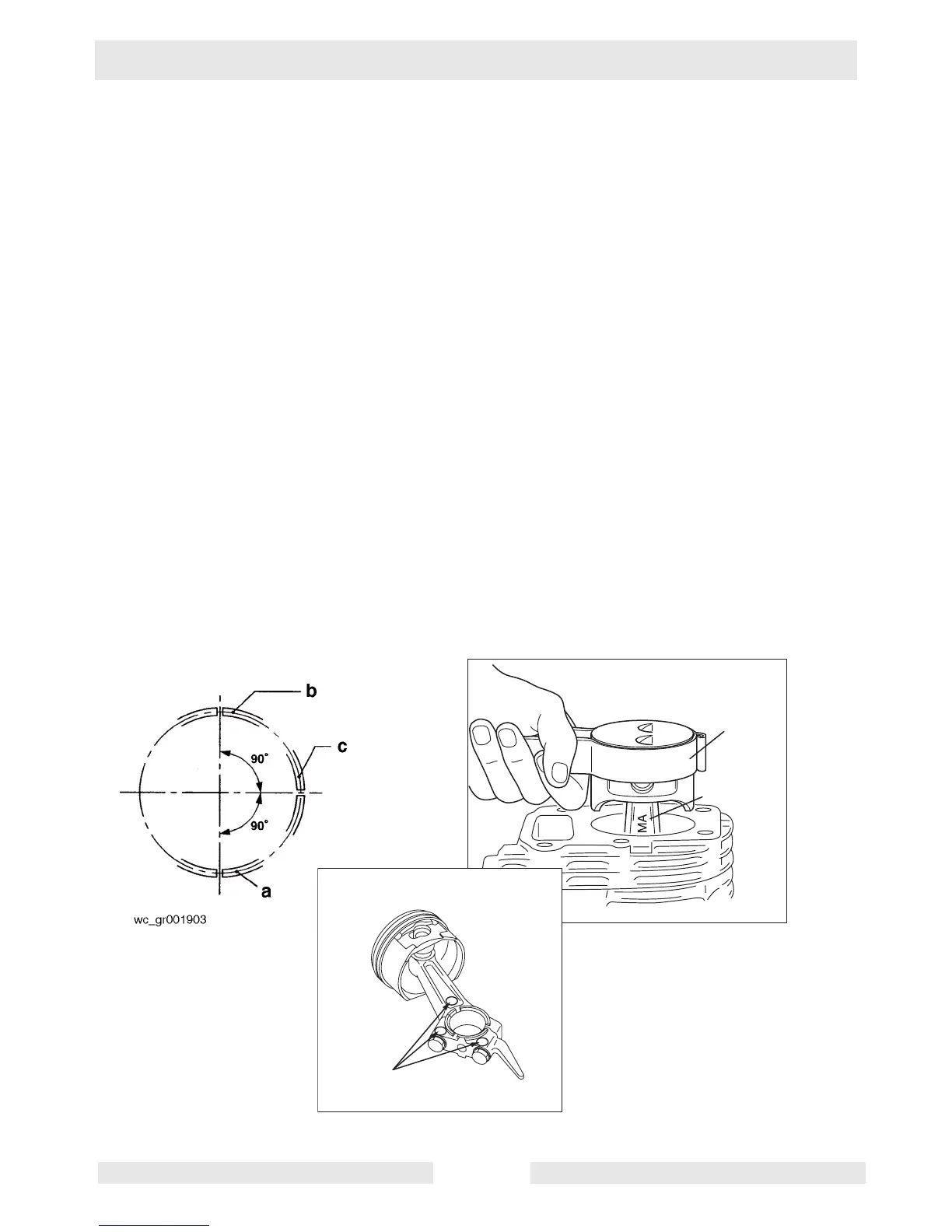

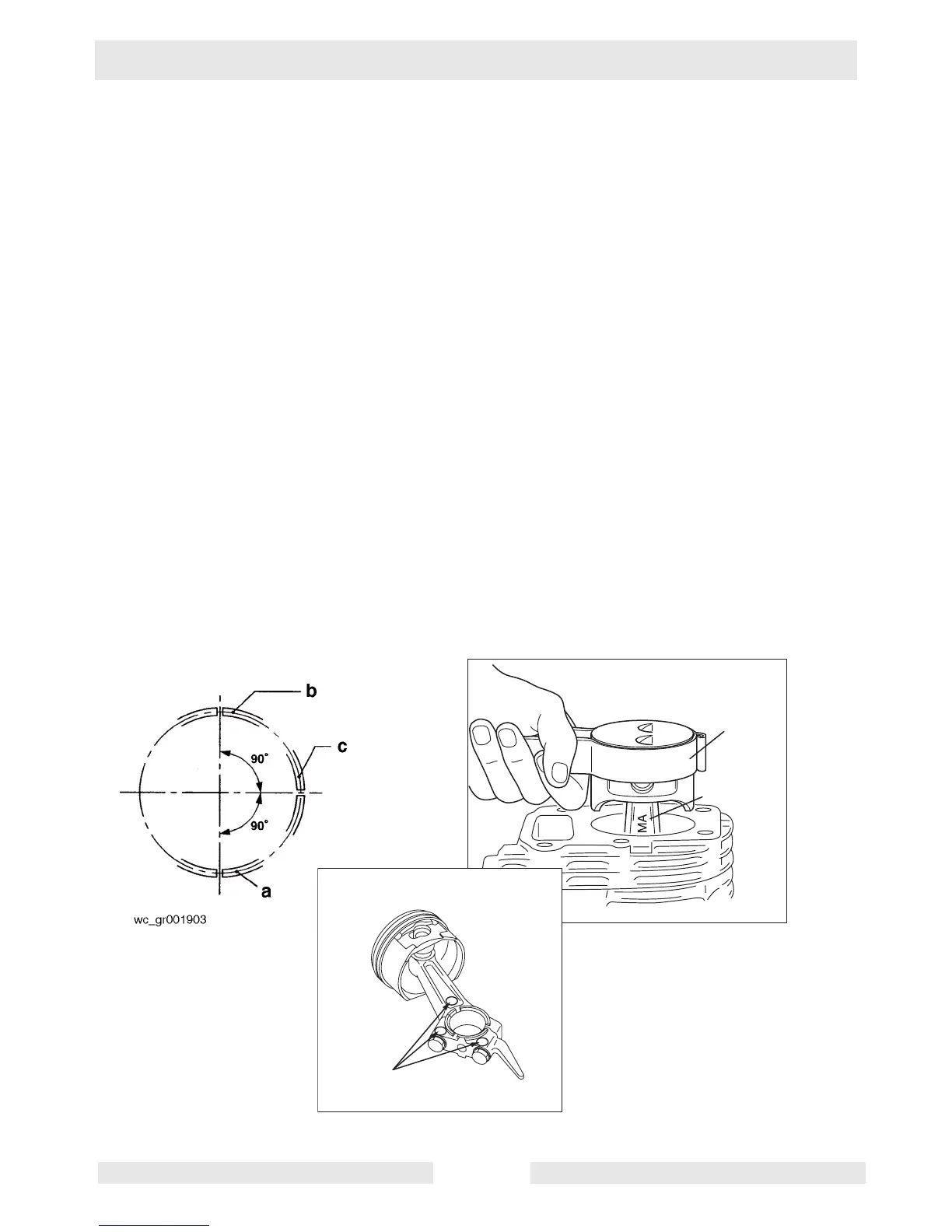

8.5 Installing Piston

See Graphic: wc_001902, wc_gr001903, and wc_gr001904

8.5.1 Position the piston rings so that the gaps in the rings are at 90°

intervals from each other (a = top ring, b = second ring, c = oil ring).

8.5.2 Apply oil to the piston rings, the cylinder bore, and the large end of the

connecting rod.

8.5.3 Position the “MA” mark on the crankshaft so that it faces the flywheel

side of the engine when assembled. Then, using a ring guide (d), hold

the piston rings in and lower the piston into the cylinder.

Note: If you do not have a ring guide, hold the piston rings in with your

fingers while tapping lightly on the piston head with a block of wood or

rubber mallet.

8.5.4 Rotate the crankshaft down to the bottom dead center and lightly tap

the piston head until the large end of the connecting rod touches the

crank pin.

8.5.5 To mount the connecting rod, line up the matching marks (e) and fit the

connecting rod cap to the connecting rod. Secure the two halves

together using two M5 bolts. Torque bolts to: 5.9–7.8 Nm (4.3–5.7

ft.lbs).

8.5.6 Check for free movement of the connecting rod by turning the

crankshaft slowly.

"MA"

d

wc_gr001902

wc_gr001904

e

Loading...

Loading...