WM 90 Repair Reassembly Procedures

wc_tx000389gb.fm 71

8.20 Break-in Operation

A new engine or one that has been completely overhauled by being

fitted with a new piston, rings, valves, and connecting rod should be

thoroughly run-in before being put into service.

Good bearing surfaces and running clearances between the various

parts can only be established by operating the engine under reduced

speed and loads for a short period of time.

Run-in the engine according to the schedule below. During the run-in

period, check for oil leaks, make final carburetor adjustments, and

regulate the engine operating speed.

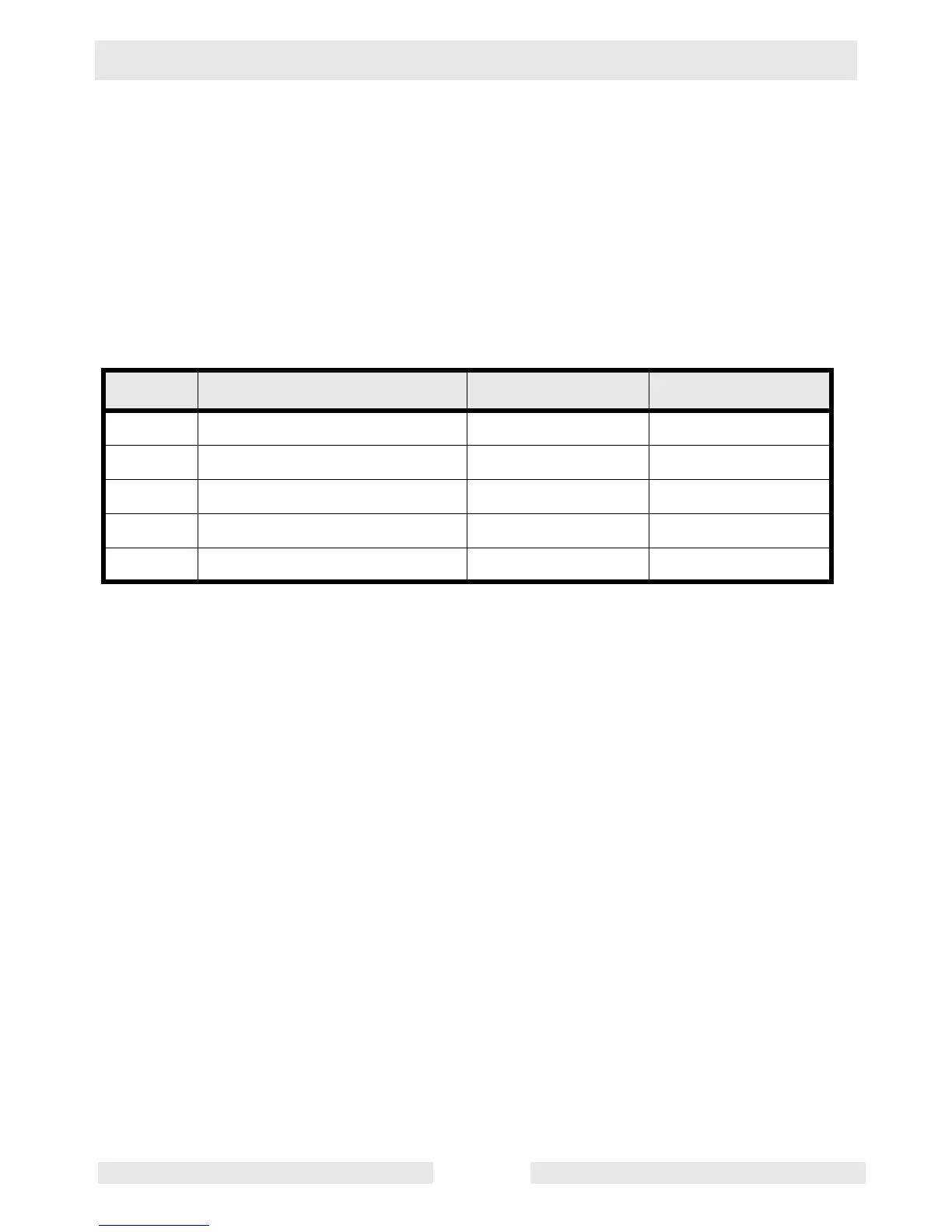

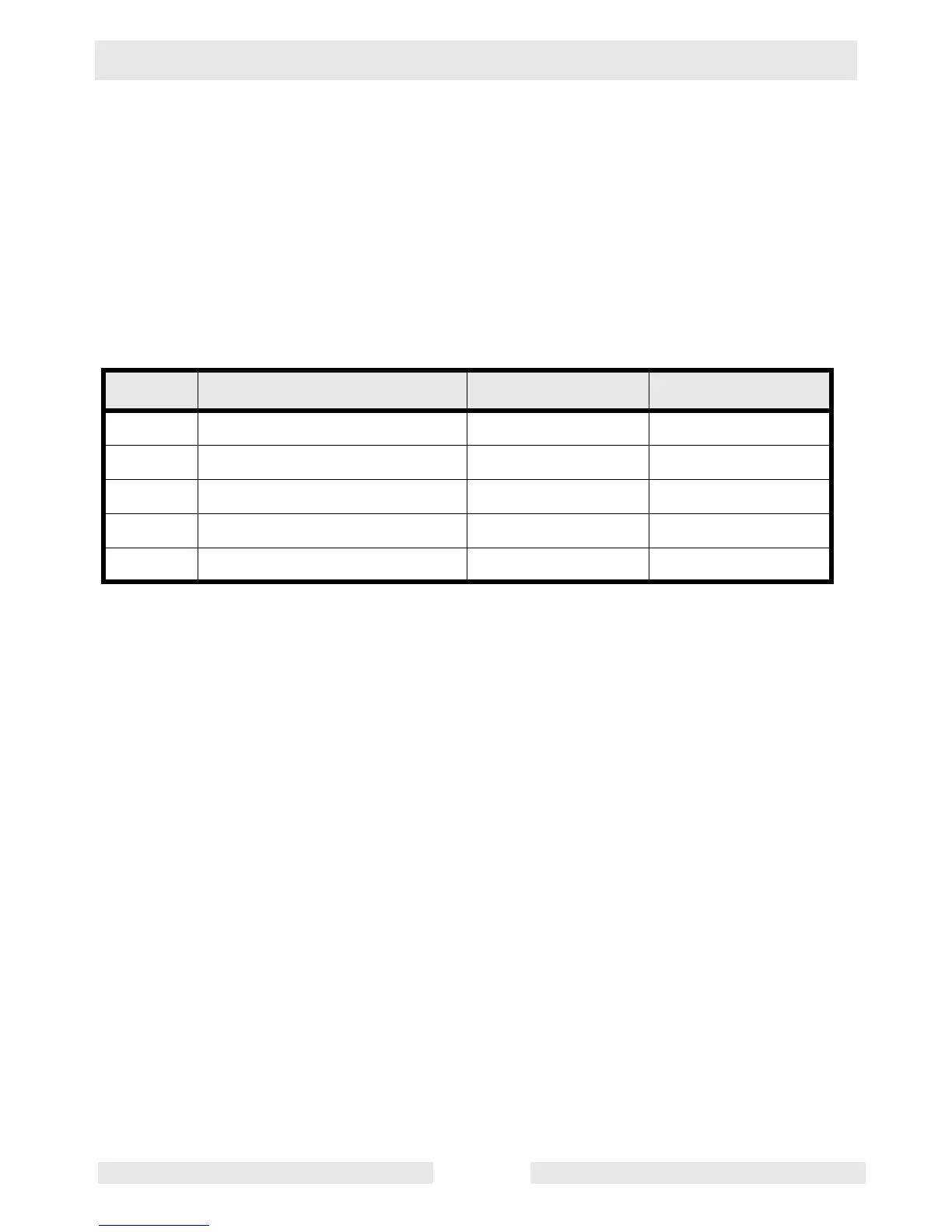

Step Engine Load Speed (rpm) Duration (min.)

1 No load 2500 10

2 No load 3000 10

3 No load 3600 10

4 0.7 kW (1.0 hp) 3000 30

5 1.0 kW (1.9 hp) 3600 60

Loading...

Loading...