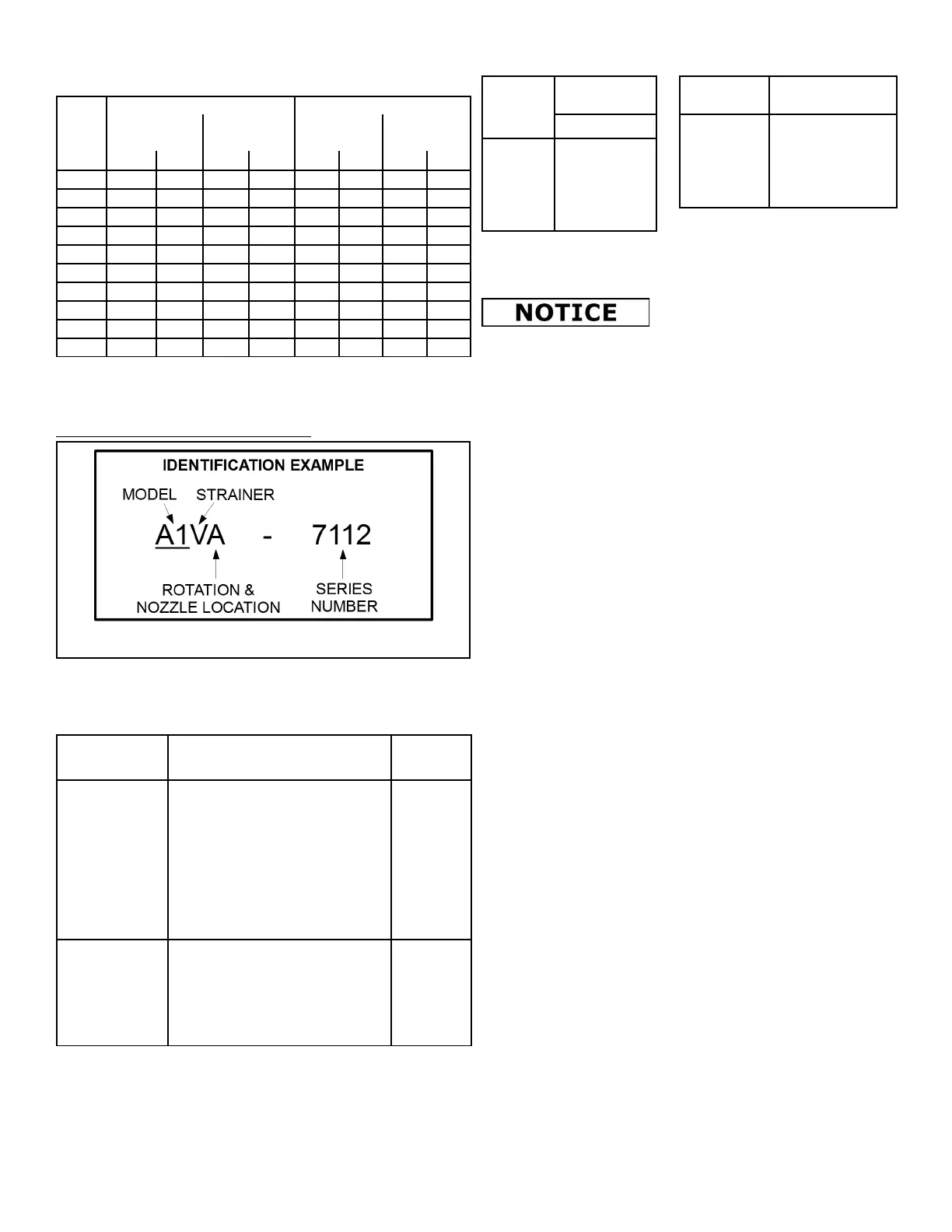

Table 5: Two-Stage, Two-Pipe

Maximum Line Length (H + R)

Lift “H”

(Figure

19)

1725 RPM 3450 RPM

3/8” OD

Tubing

1/2” OD

Tubing

3/8” OD

Tubing

1/2” OD

Tubing

3GPH 3GPH 3GPH 3GPH 3GPH7GPH3GPH7GPH

0' 100' 91' 100' 100' 93' 80' 100' 100'

2' 100' 83' 100' 100' 85' 73' 100' 100'

4' 89' 75' 100' 100' 77' 66' 100' 100'

6' 80' 67' 100' 100' 69' 59' 100' 100'

8' 70' 59' 100' 100' 60' 52' 100' 100'

10' 61' 51' 100' 100' 52' 45' 100' 100'

12' 51' 43' 100' 100' 44' 38' 100' 100'

14' 41' 35' 100' 100' 36' 31' 100' 100'

16' 32' 27' 100' 100' 27' 24' 100' 100'

18' 22' -- 88' 74' -- -- 76' 65'

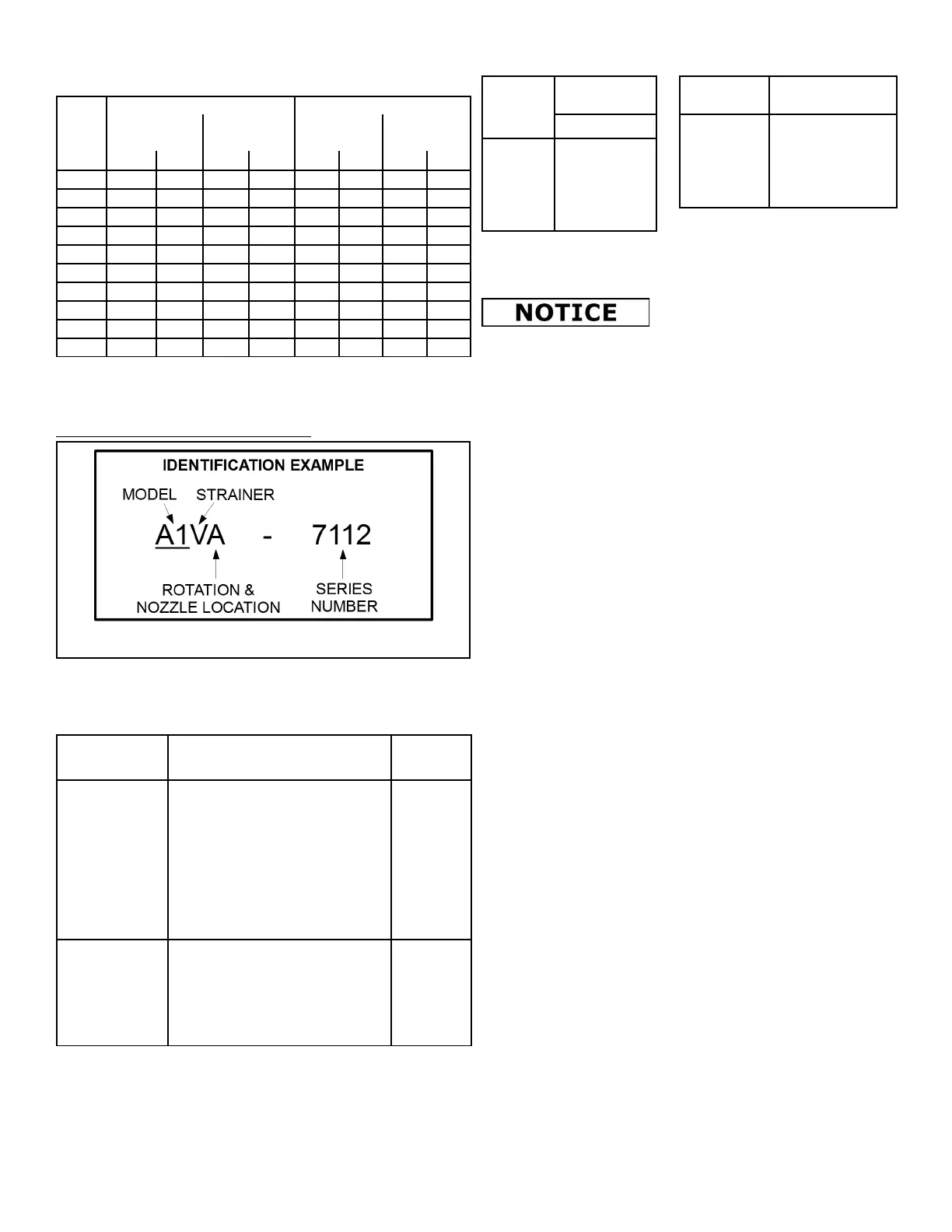

PUMP USAGE IDENTIFICATION

Figure 20: Pump Identification Example

Table 6: Max Nozzle Capacity for

Various Pump Models

MODEL

MAX. NOZZLE CAPACITY

(GPH) AT 100 PSI

RPM

A2V-2000 3 3450

A1V-7100 3 1725

A2V-7100 3 3450

A2V-7400 3 3450

A1Y-7900 7 1725

A2Y-7900 7 3450

B1V-8200 3 1725

B2V-8200 3 3450

B1Y-8900 7 1725

B1Y-8900 7 3450

Table 7: Strainer and Nozzle Rotation

STRAINER

TYPE

U.L. STRAINER

RATING (GPH)*

DESIGNATOR

ROTATION/NOZZLE

LOCATION

#2 FUEL OIL A RH/RH

V 3 B RH/LH

Y 7 C LH/LH

T 23 D LH/RH

G 34

* Maximum firing rate not to exceed maximum nozzle

capacity or strainer rating, whichever is LESS. A greater

firing rate requires a suitable external strainer.

All installations should be made

with local and national codes.

NOZZLE SELECTION

Use the nozzle with the proper size, type and spray angle

that the heater manufacturer recommends.

There are 3 different nozzle types: Hollow Cone (Type A),

Solid Cone (Type B), or Partially Solid (Type W).

Hollow cone nozzles are generally used in burners with a

hollow air pattern and also for use in burners firing at less

than 1.00 GPH. Hollow cone nozzles generally have more

stable spray angles and patterns under adverse conditions

than solid cone nozzles of the same flow rate.

Solid cone nozzles produce a spray that distributes droplets

uniformly throughout the complete pattern. These nozzles

are generally used in larger burners firing above 2.00 or

3.00 GPH to provide smoother ignition. They can also be

used where the air pattern of the burner is heavy in the

center or where long fires are required.

Type W nozzles produce a spray that is neither completely

hollow nor solid. These nozzles frequently can be used in

place of either solid or hollow cone nozzles between 0.40

GPH and 8.00 GPH, regardless of the burner’s air pattern.

The lower flow rates tend to be hollow. Higher flow rates

tend to be more solid. Type W nozzles can be used in

place of A or B types to reduce specific problems.

The nozzle size is defined by the gallons of oil used per

hour at a pump pressure of 100 psi. Table 8 shows the

effects of pressure on nozzle flow rates.

12

Loading...

Loading...