PREPARE INSTALLATION SITE

GENERAL INFORMATION

When installing the appliance and/or burner, be sure to

provide adequate space for easy service and maintenance.

Prior to installation of the oil burner, the heating system

should be carefully inspected for defects and cleanliness.

The flue passages and heat absorbing surfaces must be

clean to ensure maximum heat transfer. Soot acts as an

insulator, which retards the transfer of heat.

The combustion chamber, flue gas passages, and all doors

and openings must be tightly sealed to eliminate air

infiltration. Excess air decreases CO

2

levels and thus

lowers efficiency. Inspect the flue and chimney for leaks

and obstructions.

Be sure the chimney is of adequate size and height. Install

a draft regulator the same size as the flue pipe (see page 3

under Chimneys and Draft Regulators).

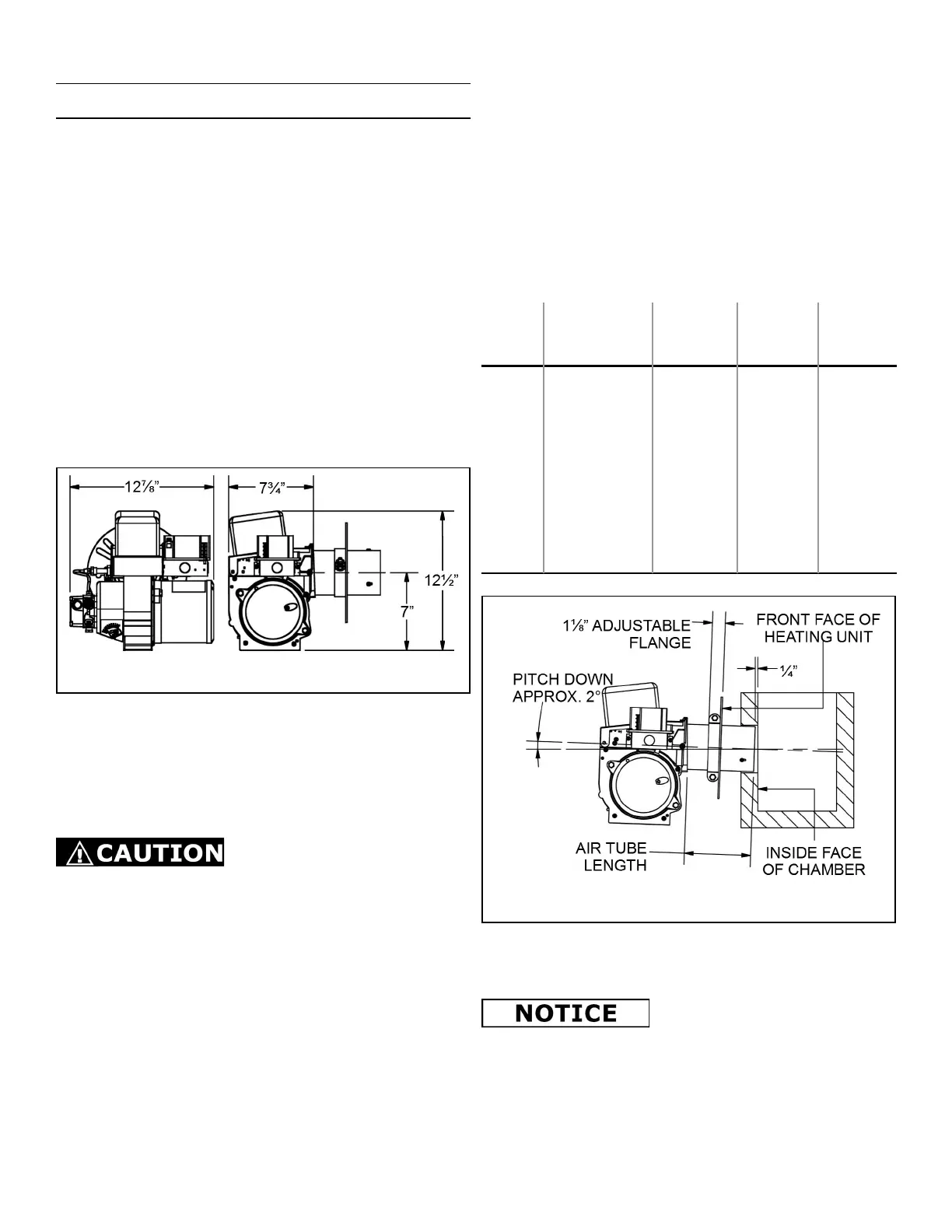

Figure 1: Overall Burner Dimensions

COMBUSTION CHAMBER

The purpose of a combustion chamber is to maintain a high

flame temperature by reflecting the heat back into the flame.

A high temperature ensures greater combustion efficiency

and lower stack losses. An insulating refractory or a Fiber

Fax type chamber can be used with this burner.

Caution should be taken when

installing Flamelock™ burners in

stainless steel combustion chambers, because of the higher

temperature levels produced by high performance flame

retention burners. The temperature may exceed the

temperature ratings of the stainless steel chamber and can

result in chamber burnouts.

It is important to select and install, if necessary, the correct

size chamber on a conversion job. (Suggested chamber

dimensions are shown in Table 1.) On the Flamelock™

conversion burners, the atomized oil burns just off the

Flamelock™ cone. On all oil burners, the atomized oil must

not touch the sides or bottom of chamber, or smoke will

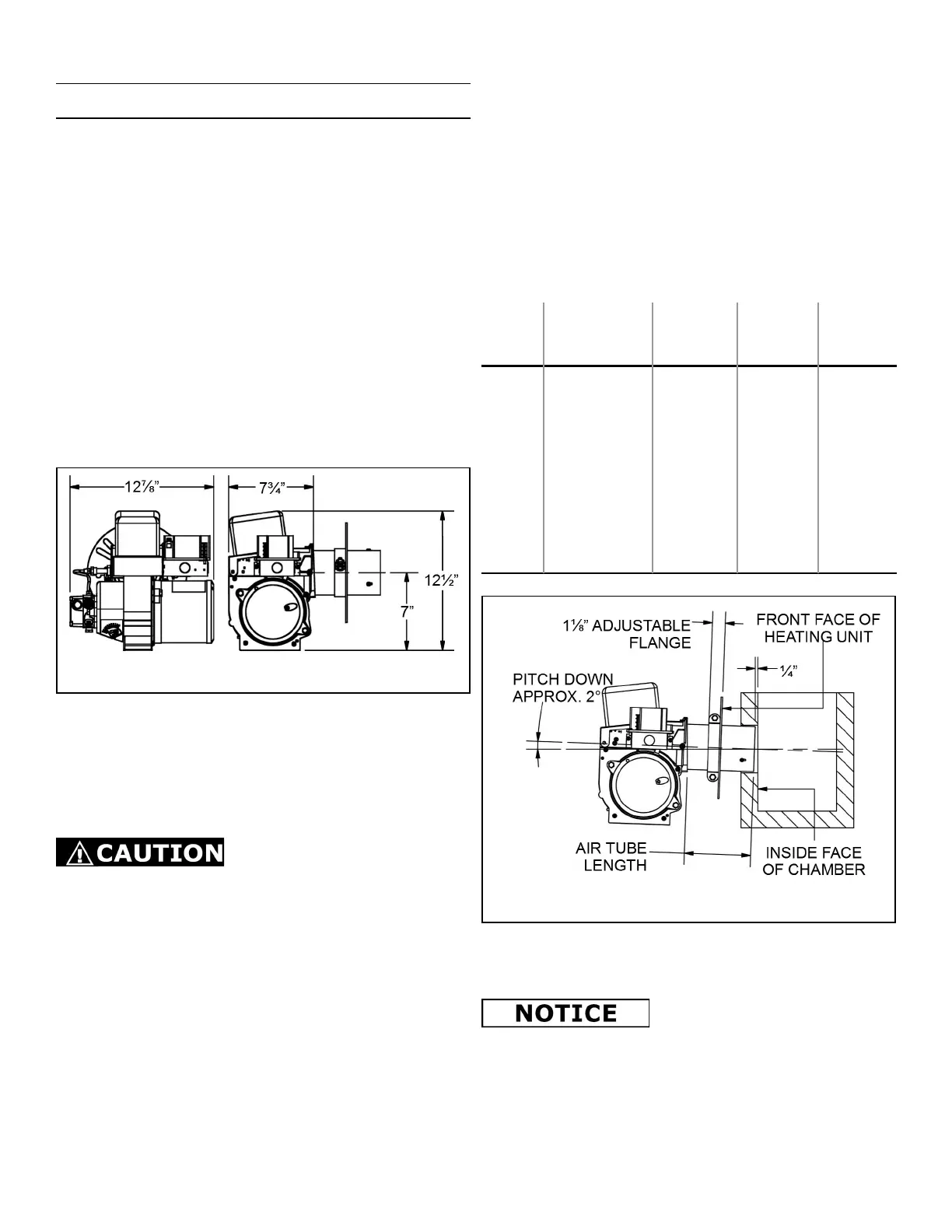

result (see Figure 21, page 13). Install the burner so the

face of the air cone of burner is set 1/4” behind the inside

face of the chamber (See Figure 2).

To eliminate the smoke, excess air will be required, resulting

in high stack temperature and lower combustion efficiency.

When you are replacing a standard burner with a flame

retention burner, take the following precautions:

1. Use pliable ceramic liner to line the inside of chamber.

2. Adjust burner (see “Final Adjustments” on page 7).

Table 1: Suggested Combustion Chamber

Dimensions

Conversion or Upgrading

Chamber Dimensions (in inches)

Firing

Rate

(GPH)

Square

Chamber

Diameter

Round

Chamber

Height

Nozzle to

Floor

0.50 7 x 7 8 11 5 – 6

0.75 8 x 8 9 12 5 – 6

0.85 8½ x 8½ 9 12 5 – 6

1.00 9 x 9 10⅛ 12½ 5 – 6

1.25 10 x 10 11¼ 12½ 5 – 6

1.35 10½ x 10½ 11¾ 12¾ 5 – 6

1.50 11 x 11 12⅜ 13 5 – 6

1.65 11½ x 11½ 13 13¾ 5 – 6

2.00 12⅝ x 12⅝ 14¼ 13¾ 6 – 7

2.50 14¼ x 14¼ 16 14 7 – 8

3.00 15½ x 15½ 17½ 15 7 – 8

The “Air Tube Length” is the distance from the front of the

aluminum fan housing to the face of the Air Cone.

The maximum insertion depth of

any given air tube is reduced by

the thickness of the adjustable flange. Example: A 6” air

tube can only be inserted about 5”.

2

Figure 2: Combustion Chamber Detail

Loading...

Loading...