Webasto Product N.A., Inc. 32 www.techwebasto.com

FUNCTIONAL ADJUSTMENTS DBW 2010/2020/300 COOLANT HEATERS

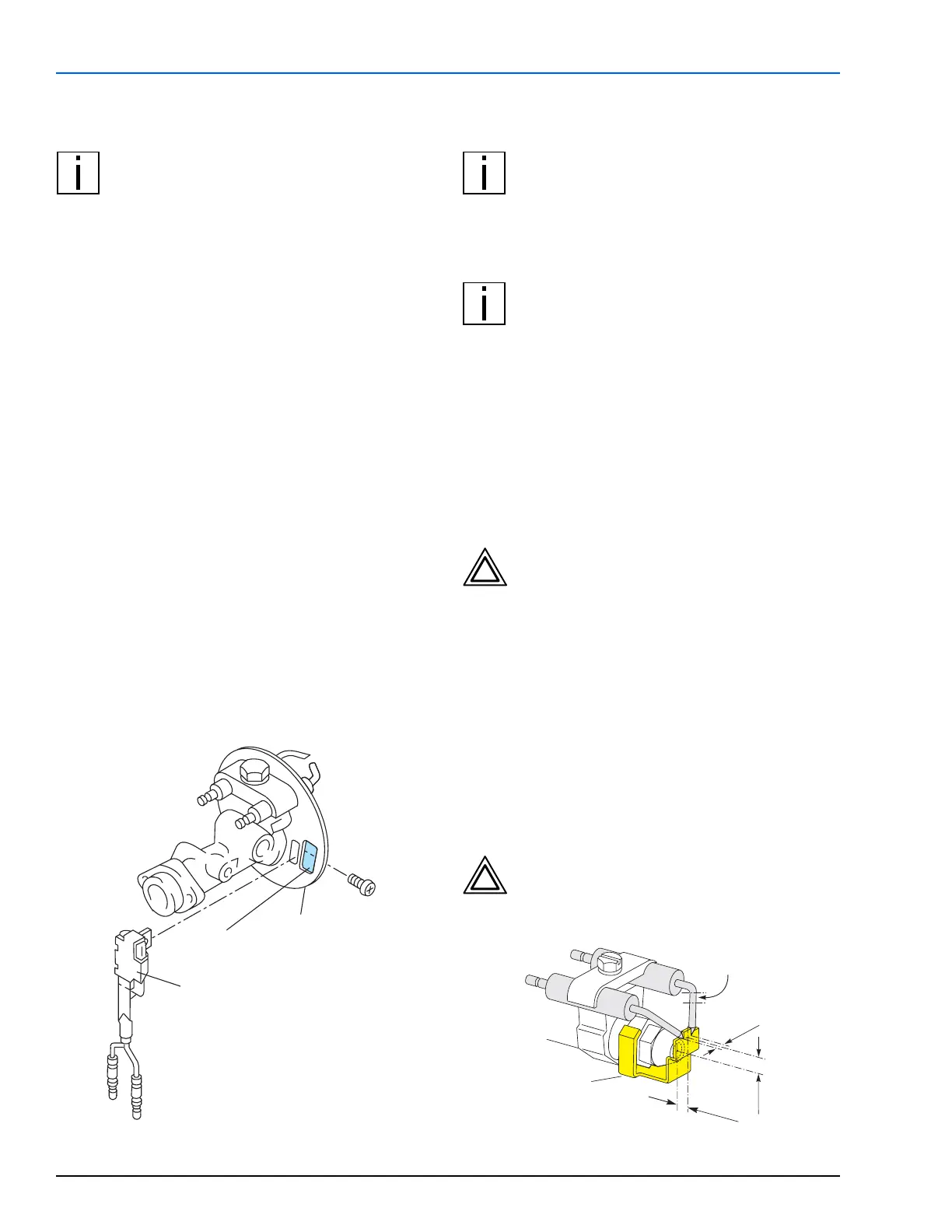

6.2.2 FLAME DETECTOR RESISTANCE CHECK

NOTE: The glass bulb of the flame detector

and the viewing glass of the window (refer to

Fig. 22) are to be cleaned if contaminated.

In case of damage, cracked glass bulb or not obtaining

the rated values, replace the flame detector.

C

HECK

– Swing burner head open (see Sec. 8.5.1)

– Disconnect flame detector leads

– Connect flame detector leads to ohm meter

– Cover flame detector glass bulb with your thumb

– Check resistance (rated value: < 20 kOhm)

– Uncover flame detector and expose to strong light

– Check resistance (rated value: < 200 Ohm)

A

LTERNATE METHOD USING TESTER (P/N 1302691A)

– Exchange control unit with tester and swing burner

head open (see Sec. 8.5.1).

– Watch “Flame Control” LED while holding your

thumb over the flame detector glass bulb. LED will

darken considerably.

– Remove your thumb, LED will brighten considerably.

(Shine a bright light on the flame detector if in a

dimly lit area.)

– The fluctuation of the LED between dim and bright

will indicate the flame detector is working properly.

Figure 22: Flame Detector Check

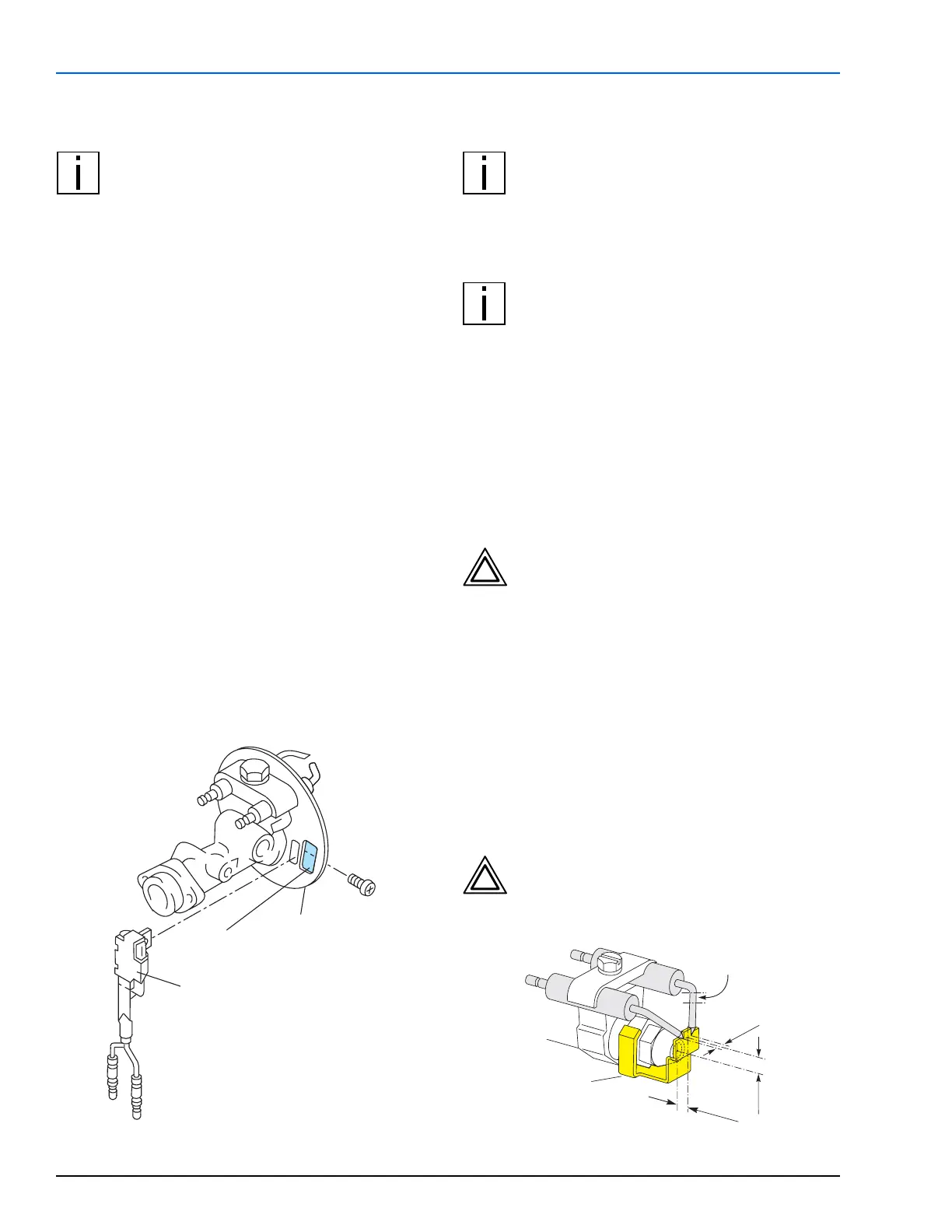

6.2.3 IGNITION ELECTRODE CHECK AND SETTING

NOTE: The insulation body of the ignition

electrodes must not show any damage.

Damaged insulation of the electrodes requires

their replacement. Setting ignition electrodes

with a spacing beyond the tolerances shown in

Fig. 23 may or will cause ignition failures.

NOTE: The ignition electrodes can be set with

the setting gauge as shown. In addition the

front edge of the setting gauge must rest

against the atomizer nozzle and the tips of the

electrodes in both notches.

C

HECK

– Swing burner head open (see Sec. 8.5.1)

– Insulation body of the ignition electrodes for

damages

– Electrode spacing with setting gauge according to

Fig. 23.

CAUTION: Do not touch the nozzle drilling

while measuring the electrode spacing.

Keep the electrode setting gauge clean and

free of contaminates.

S

ETTING

– Place setting gauge over nozzle as shown.

– Loosen clamp bolt until electrode can be moved with

slight effort

– If necessary, electrodes can be bent slightly to

conform to the setting gauge notches. Grip with

pliers at the bending point only.

– Once set, snug up clamp bolt and check electrode

spacing once again to confirm setting.

CAUTION: Do not over-tighten or bottom

out clamp bolt. Doing so will distort the

clamp causing the electrodes to spread

apart.

Figure 23: Setting of Ignition Electrodes

Flame Detector

Window

Screw

Disc

5 ±

0.5

8 ±

0.5

4.5 ±

0.5

If necessary,

grip here to bend

Millimeters

Setting Gauge

P/N 310646

Loading...

Loading...