38 WILO SE 08/2013 Ed.04 DIN A4

English APPENDIX

10.1. Acknowledging faults

After a fault occurs, a visual and audible warning is

output.

BybrieypressingtheBuzzerOFF/resetbutton,

the audible alarm is deactivated and collective fault

signal relay (SSM) acknowledged.

When held down for longer (min. 1 sec), the fault is

acknowledged and the control is reenabled.

A fault can only acknowledged once it has been

eliminated!

10.2. Fault signals

LED lights up red

Cause:permittedratedcurrenthasbeenexceeded,

excesscurrentreleasehasbeeninitiated

Solution: Check pump and setting of DIP switch

LED ashes red

Cause:Ratedcurrentbelow300mAduringopera-

tion or phase L2 missing

Solution: Check mains connection of switchgear

and pump connection

LED lights up red

Cause: Winding temperature monitoring has been

triggered

Solution: Check pump and wiring (converter bridge

may be missing); check pump operating conditions

LED lights up red

Cause: High-water alarm has been triggered.

Solution: Check pump/unit operating conditions

and level settings

All LEDs light up simultaneously for 2sec.

Cause: Button lock active

Solution: Deactivate the button lock by simulta-

neously pressing down the Manual Mode, Stop and

AutomaticModebuttons(forapprox.1s).

All LEDs light up from right to left.

Cause: Incorrect phase sequence in mains connec-

tion

Solution: Swap over 2 phases in the switchgear's

mains connection

10.3. Fault memory

The switchgear has a fault memory. The last fault

is stored retentively in the fault memory.

Opening the fault memory

By pressing down the Stop and Automatic Mode

buttons simultaneously, the last fault is indicated

by the corresponding LED.

Deleting the fault memory

The fault memory is deleted by simultaneously

pressingandholdingdown(forapprox.1s)the

Manual Mode and Stop buttons.

10.4. Further steps for troubleshooting

If the points listed here do not rectify the fault,

contact Wilo Customer Service. They can help you

as follows:

• Telephone or written support from Wilo Customer

Service

• On-site support from Wilo Customer Service

• Inspection or repair of the switchgear at the

factory

Please note that you may be charged for some

services provided by our Customer Service. For

more details, please contact Wilo Customer

Service.

11. Appendix

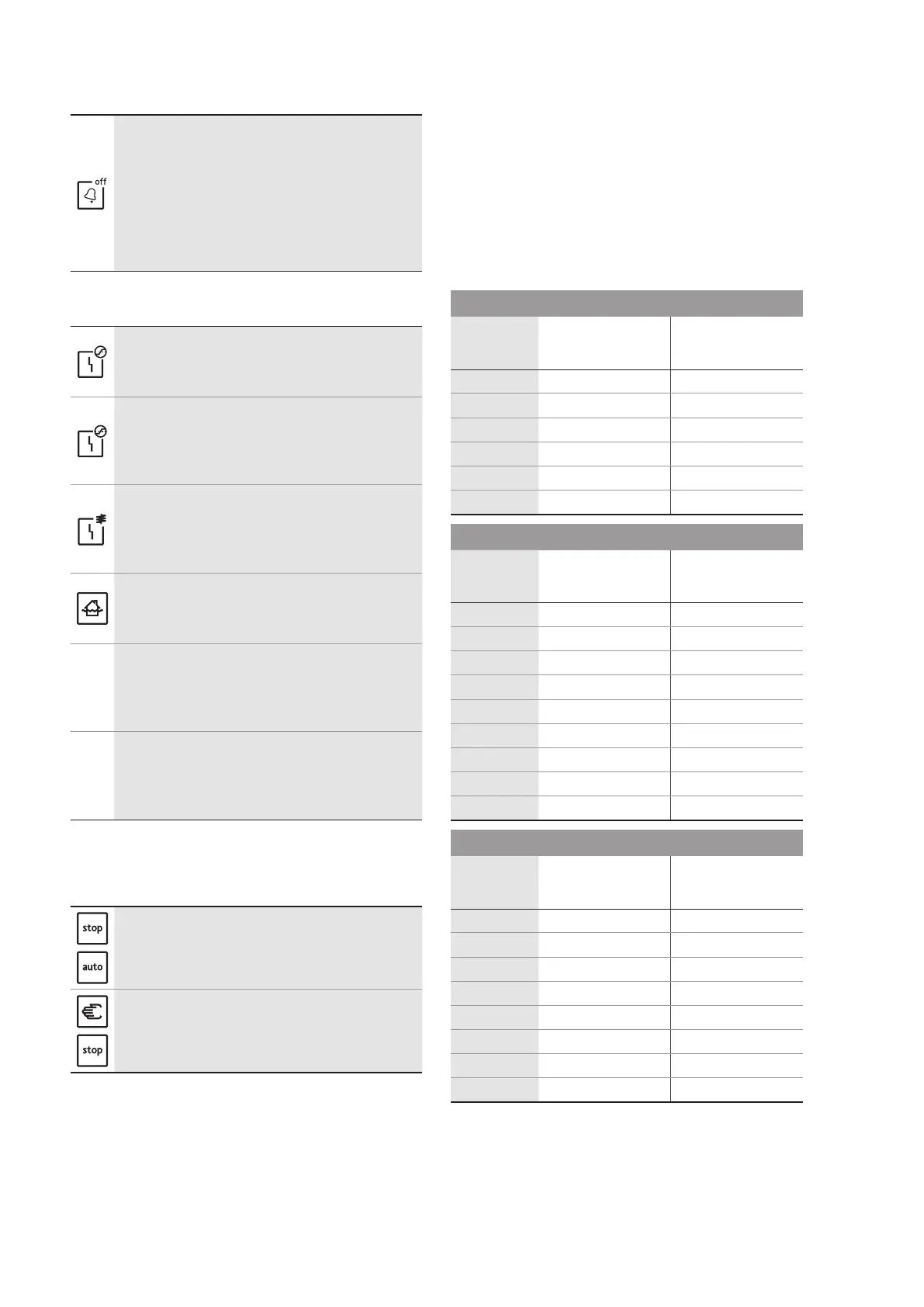

11.1. System impedance tables

System impedances for 1~230 V, 2-pole, direct starting

Power System impedance Connections/h

kW ohms

1.5 0.4180 6

2.2 0.2790 6

1.5 0.3020 24

2.2 0.1650 24

1.5 0.2720 30

2.2 0.1480 30

System impedances for 3~400 V, 2-pole, direct starting

Power System impedance Connections/h

kW ohms

2.2 0.2788 6

3.0 0.2000 6

4.0 0.1559 6

2.2 0.2126 24

3.0 0.1292 24

4.0 0.0889 24

2.2 0.1915 30

3.0 0.1164 30

4.0 0.0801 30

System impedances for 3~400 V, 4-pole, direct starting

Power System impedance Connections/h

kW ohms

3.0 0.2090 6

4.0 0.1480 6

2.2 0.2330 24

3.0 0.1380 24

4.0 0.0830 24

2.2 0.2100 30

3.0 0.1240 30

4.0 0.0740 30

11.2. Spare parts

Spare parts can be ordered from Wilo Customer

Service. To avoid queries and incorrect orders, the

serial and/or article number must always be stat-

ed. Subject to change without prior notice

Loading...

Loading...