COMMISSIONING

Greenstar i System Compact - 6 720 807 726 (2013/05) 35

Fig. 62 L.P.G. pressures

5.5.2 CHECKING THE GAS RATE

▶ The gas rate should be measured at the gas meter after the boiler has

been operating for a minimum of 10 minutes at maximum output.

▶ See Technical data section on page 6 of this manual for gas rates and

CO/CO

2

ratios.

▶ Where a gas meter is not available (e.g. L.P.G.) the CO/CO

2

must be

checked.

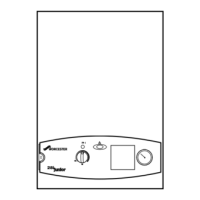

5.5.3 GAS RATING TEST

▶ Ensure all other gas appliances are isolated.

1.Set the boiler to maximum output by pressing and the

buttons together for at least 5 seconds.

The chimney sweep symbol (1) will be displayed at the top of the

screen and the word “Max” will flash at the bottom of the screen. The

boiler will ramp up to maximum output in 30 to 35 seconds.

Fig. 63 Setting boiler to maximum

▶ Ensure that the boiler has stabilised at maximum output.

▶ Carry out Gas rating procedures as described in “Essential Gas

Safety” third edition.

▶ If pressure and gas rate are satisfactory press the button again

and the boiler will return to normal operation.

– If left in the service mode the control will return to normal operation

after 15 minutes.

5.5.4 CHECKING FOR LEAKS DURING OPERATION

▶ Use an approved leak detector to check all connections for possible

leaks. The product must be certified as a gas leak testing agent.

▶ Do not allow the product to come into contact with the electrical

wiring.

5.6 DOMESTIC HOT WATER

Controlling the hot water temperature:

The hot water temperature can be set to between approximately 40°C

and 70°C using the DHW temperature control.

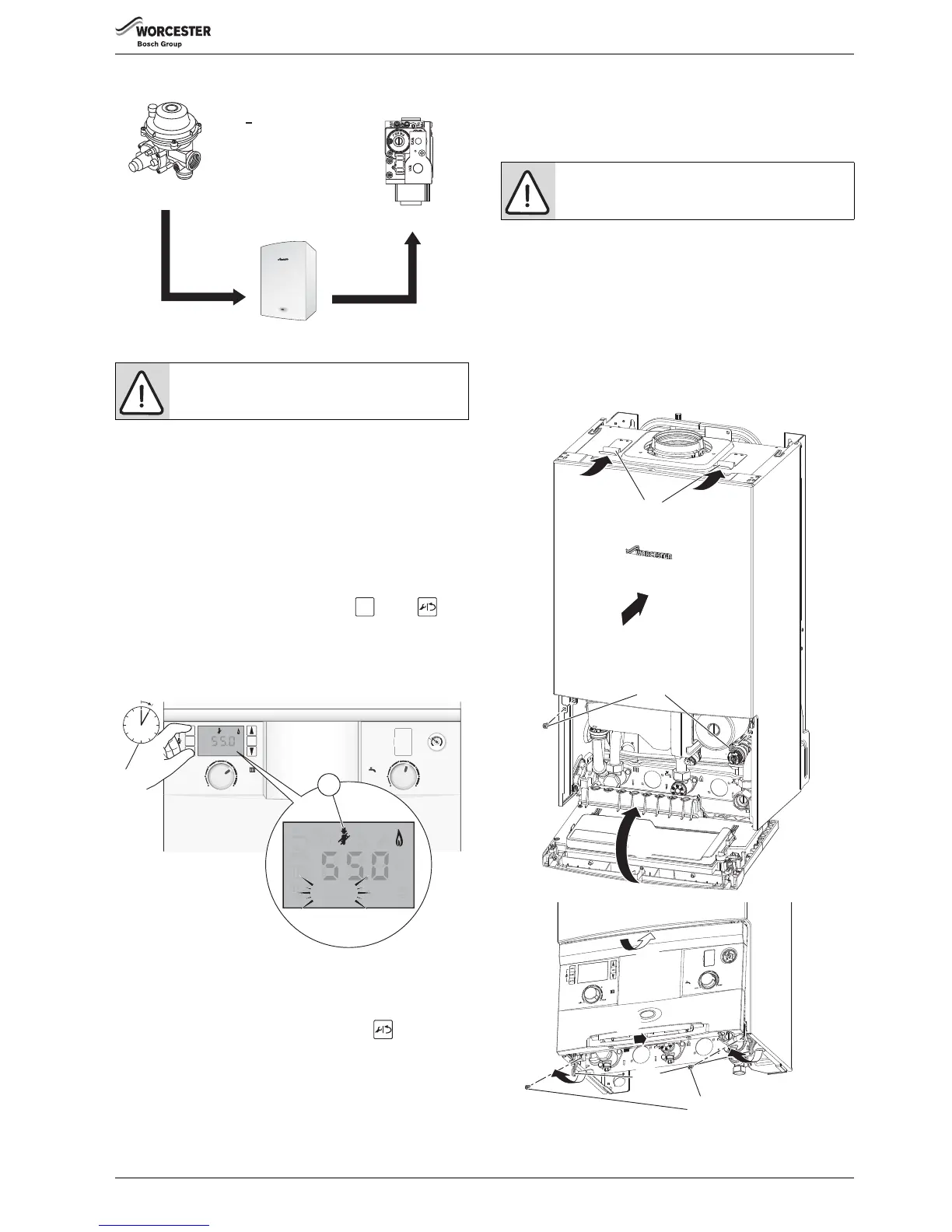

5.7 FINISHING COMMISSIONING

5.7.1 REPLACING THE BOILER CASE

1. Ensure that bottom edge of the case is engaged onto the rail of the

superstructure. Slide into place.

2. Ensure that the securing points on top of the case are properly

located.

3. Tighten the bottom two screws.

Fig. 64 Fitting case

NOTICE:

Do not continue commissioning until the correct gas

pressure is achieved.

Loading...

Loading...