FAULT FINDING AND DIAGNOSIS

Greenstar i System Compact - 6 720 807 726 (2013/05)64

7.5 FAULT CODES

Should a fault develop with this boiler (or the system), the boiler will enter a locking or blocking condition, and fault code information will be generated

as described in this section.

LOCKING ERRORS

Locking error The boiler display will flash a warning triangle and fault code. At the same time a (static) cause code will also be displayed. Manual

intervention is required following clearance of the fault:

▶ Press the reset button on the boiler fascia

Blocking error The boiler will stop operating with no fault data displayed. The cause code, in the info menu, is accessed by pressing the spanner/

return button. The condition will clear automatically when the associated fault clears e.g. waiting for an area to cool. In some cases a

blocking error has a defined time duration prior to changing to a locking condition.

Fault code Alpha numeric code indicating the fault group

Cause code Three digit number. During a blocking error (or normal operating status) it is not displayed, but accessed in the info menu via the

spanner/return button. During a locking error the cause code flashes on the display.

Maintenance

codes

These are displayed with the letter H followed by a number. The code advises of a situation that will need some attention but is not a

fault that will stop the boiler from functioning. Some of the common ones are listed:

H11

H13

Hot water outlet sensor defect, hot water can still be delivered but with less control (sensor open/short circuit or out of position)

A time has been set in the Service interval function i.e. 1 to 72 months and that time has expired. Menu 2.5F allows this feature to be

set (1 to 72), a 0 will disable this function.

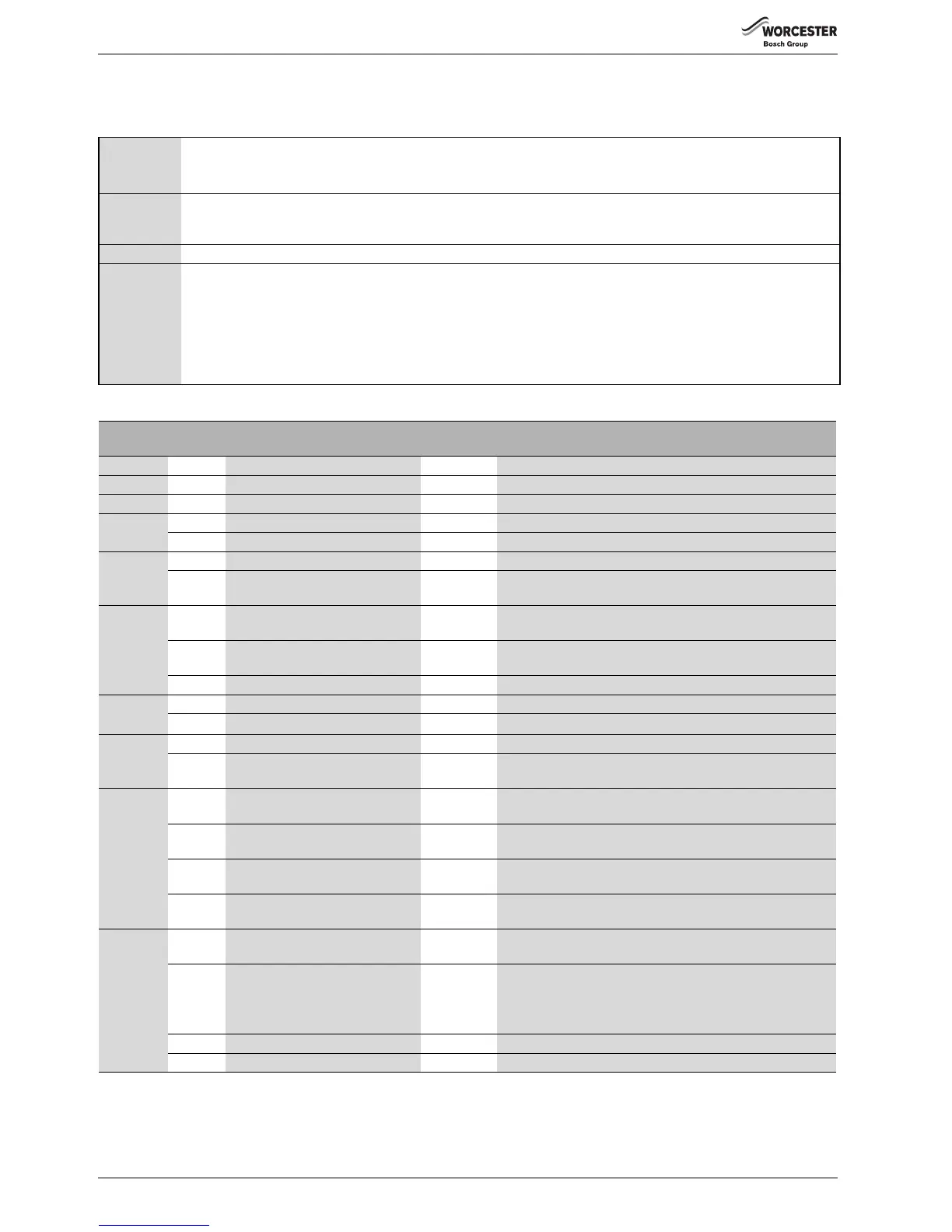

Fault codes

Cause

codes

Description Reset type Possible cause

9A 362 HCM (Heat Control Module) Reset button Incorrect HCM fitted

9U 233 HCM (Heat Control Module) Reset button Problem with the code plug (faulty or not connected)

b7 257 Internal error Replace control board.

C6 215 Fan problem Reset button Fan running too fast

216

Fan problem Reset button Fan running too slow

C7 214 Fan problem Reset button Fan not running

217 No airflow after a defined period of

time

Reset button Fan not running or airflow blocked

D1 240 Return sensor error Reset button Sensor wet or damaged (the boiler will block for 300 seconds

before this condition).

241

Return sensor error Reset button Sensor disconnected or damaged (the boiler will block for 300

seconds before this condition).

286

Return temperature too high Reset button Boiler overheat

E2 222 Flow sensor short circuit Reset button Flow sensor shorted or damaged.

223

Flow sensor open circuit Reset button Flow sensor disconnected or damaged.

E5 218 Flow temperature too high Reset button Primary flow sensor overheated

332

Primary flow sensor has exceeded

110°C

Reset button Primary flow sensor overheated

E9 219 Safety sensor temperature too high Reset button The main heat exchanger has overheated.

Maximum temperature 105C°

220

Safety sensor short circuit Reset button Maximum temperature sensor on the main heat exchanger has

failed.

221

Safety sensor open circuit Reset button Maximum temperature sensor on the main heat exchanger has not

been recognised.

224

Max temperature thermostat

activated

Reset button Flue gas thermostat overheat

EA 227 No flame detected after ignition Reset button Failure of four ignition attempts. The boiler waits 30 seconds before

another attempt is made.

229

Loss of flame signal during operation Reset button An established flame has been extinguished.

This could be caused by:

• moisture in the sump, due to a blocked sump/condensate trap.

• a strong wind into the flue.

234

Gas valve error Reset button Gas valve coil disconnected

261

Ignition timing error Reset button Flame not established during the first 4 seconds ignition period.

Table 20 Locking fault and cause code listing

Loading...

Loading...