23

4. Connection

4. Connection4. Connection

4. Connection

4.1 Connecting fluid piping

4.1 Connecting fluid piping 4.1 Connecting fluid piping

4.1 Connecting fluid piping

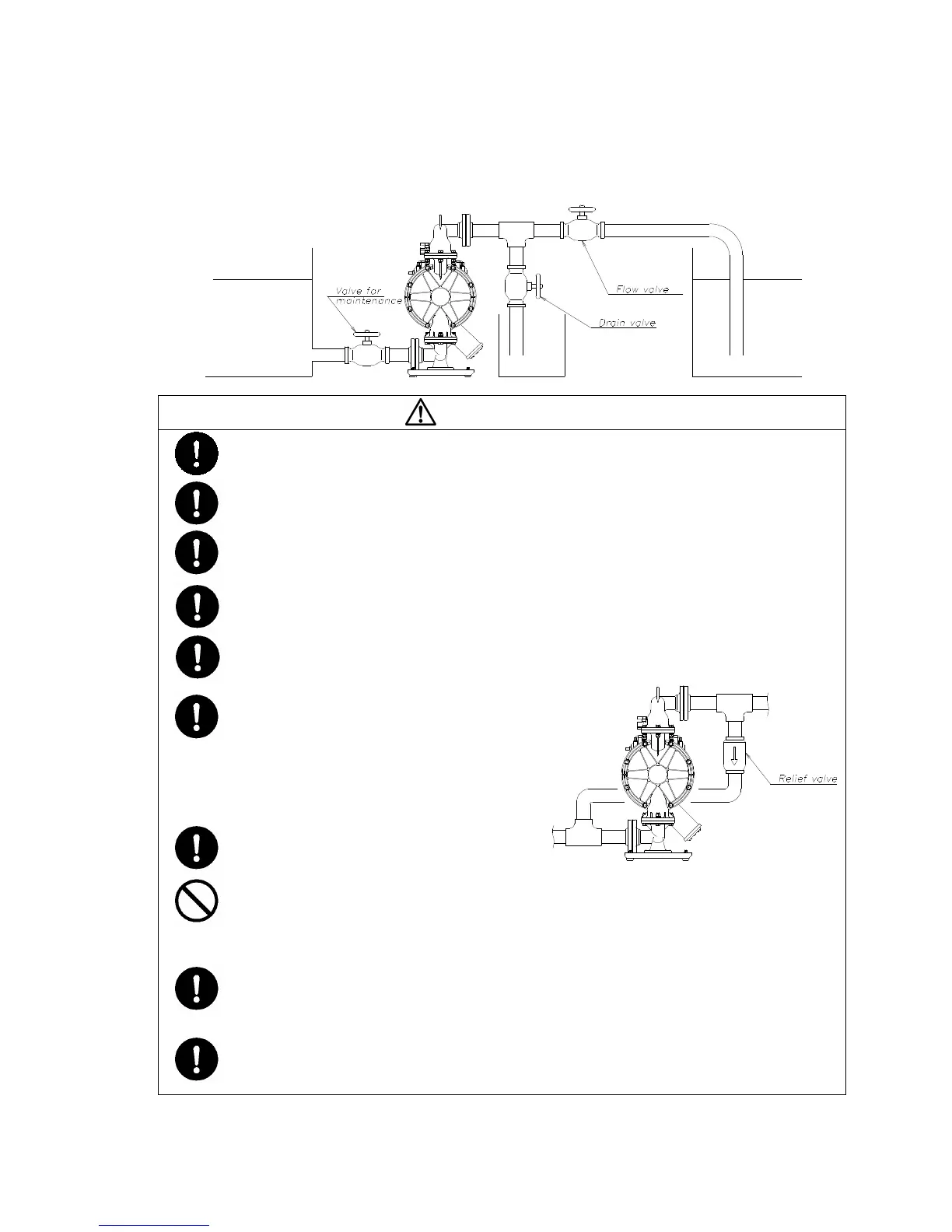

1) Connect a flow valve and a drain valve to the fluid discharge port of the pump.

2) Connect a valve for maintenance to the fluid suction intake port of the pump.

3) Connect a hose to the valve on the suction-port side and the valve of the discharge-port side of the pump.

4) Connect a hose on the suction-side intake and the discharge-port side to the respective vessels.

Fig.4.1

CAUTION

CAUTIONCAUTION

CAUTION

•Use a flexible hose to absorb pump vibration, and ground the hose.

•Make sure that there will be no external force on any connection part of the pump.

Be especially careful not to have the pump support part of the weight of the hose and the piping.

•Use a sturdy hose that will not collapse under the strong suction of the pump. Also, make sure

the hose is of more than sufficient pressure rating.

•Use a hose of a diameter the same as or larger than the pump's ports. If you use a hose of

smaller diameter, the pump's performance will be adversely affected, and it may even malfunction.

•When pumping a fluid that contains slurry, verify that the particle size is below the

slurry limitation (after p.30, 10.1 Main specifications).

If it exceeds the limitation of slurries indicated in the main specifications, attach a strainer to

the pump to stop larger particles. Otherwise, such particles may cause a malfunction.

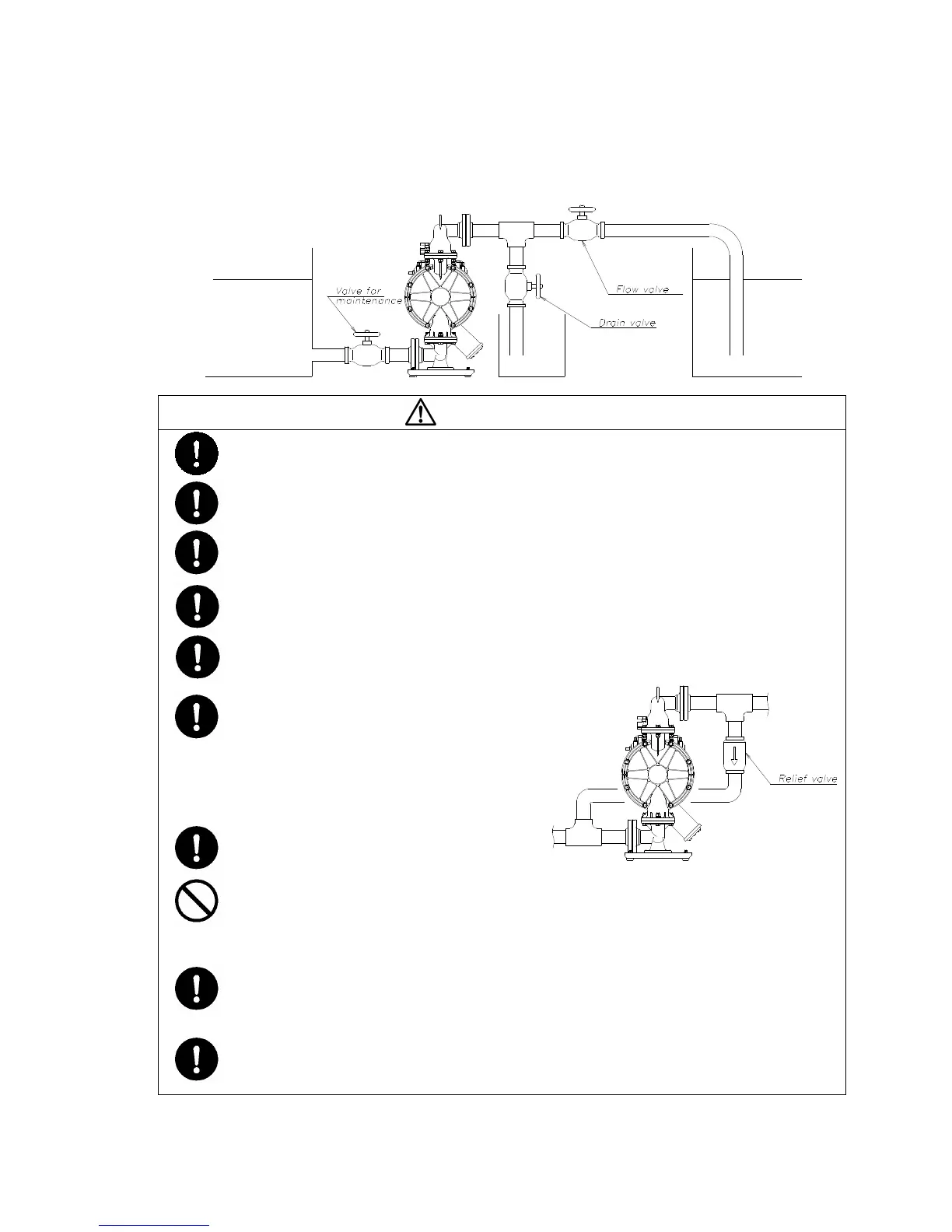

•If, depending upon the place of pump installation, the

volume of the pumped fluid changes drastically, install a

relief valve on the discharge side, and bring the pressure

down below the maximum permissible value. If, owing to

a change in the volume of fluid, the pressure inside the

pump exceeds the maximum permissible pressure, it

may cause damage.

•Keep a vessel below the relief valve to catch any

drain off.

Fig. 4.2

•When testing piping for leakage, do NOT apply pressure to the pump's inlet and outlet sides with

compressed air from outside. It may cause abnormal breakage to the diaphragm or the switching

portion. When testing the piping, either install a valve between the pump's suction inlet and the

discharge outlet and piping, or disconnect the pump from the piping and install plugs so that there

will be no pressure from outside.

•In our product inspection, clean water (pure water for the DP-F series) is used. To prevent mixture

of dirty water into the fluid to be pumped, clean the inside of the pump before finishing installation

work.

•When installing a standby pump or two pumps in parallel, be sure to provide a valve on each of

the IN and OUT sides and perform pump switching by using the liquid material valve. If the

valve of the stop-side pump is open, the diaphragm will be inverted by the discharge pressure of

the operating-side pump, resulting in damage in an early stage.

Loading...

Loading...