12.1 Maintenance and Inspection of Servodrives

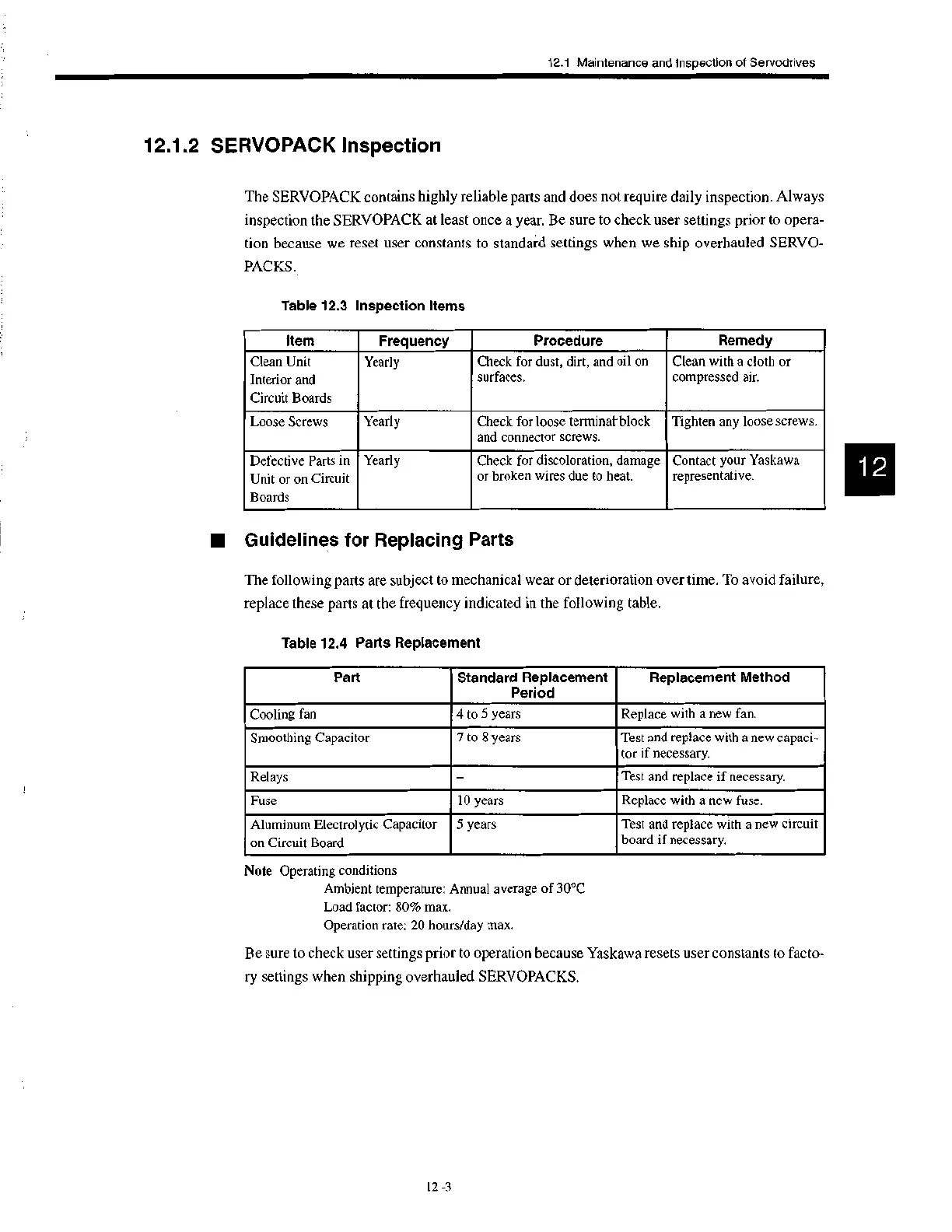

Item Frequency

Procedure

Remedy

Clean Unit

Interior and

Circuit Boards

Yearly

Check for dust, dirt, and oil on

surfaces.

Clean with a cloth or

compressed air.

Loose Screws

Yearly Check for loose terminal-block

and connector screws.

Tighten any loose screws.

Defective Parts in

Unit or on Circuit

Boards

Yearly Check for discoloration, damage

or broken wires due to heat.

Contact your Yaskawa

representative.

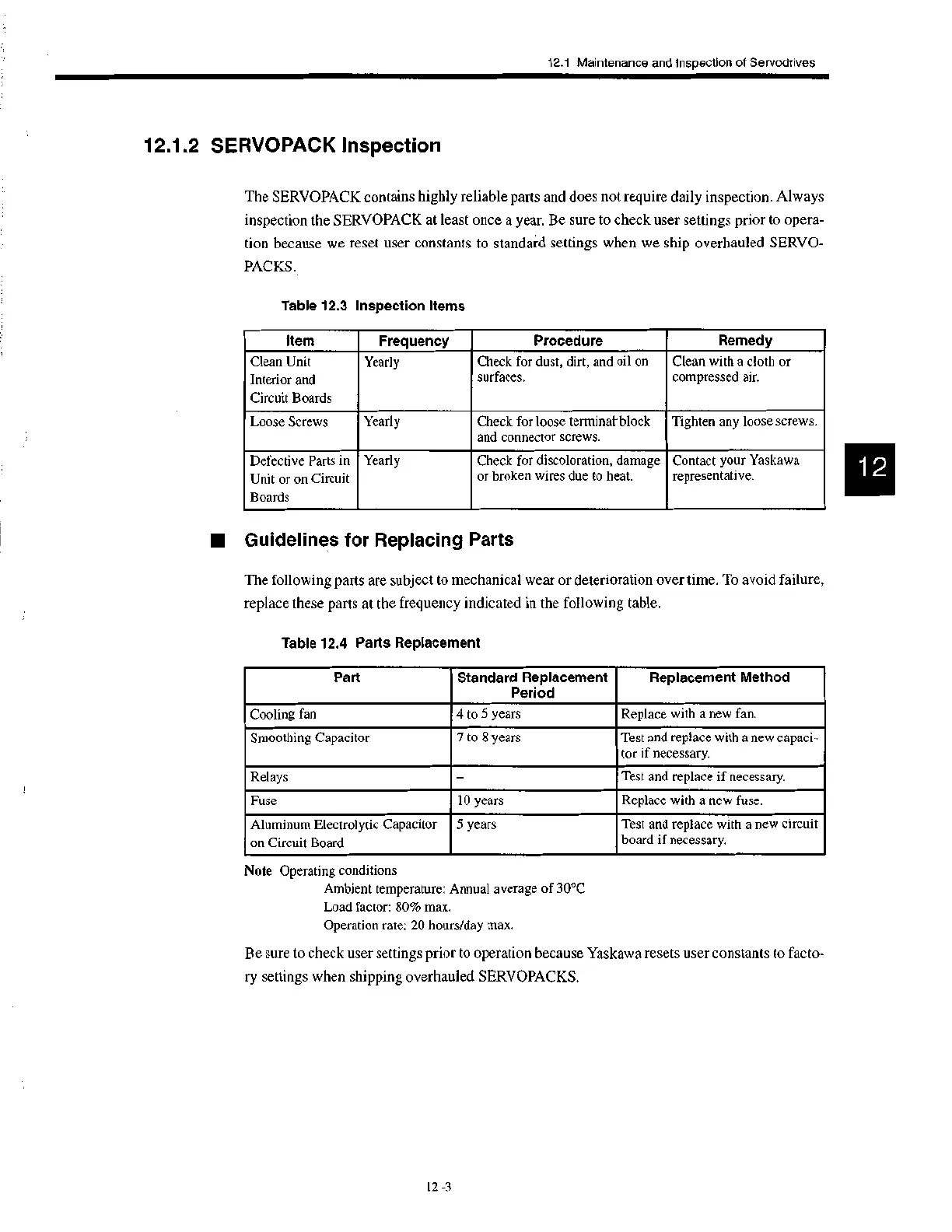

Part Standard Replacement

Period

Replacement Method

Cooling fan 4 to 5 years

Replace with a new fan.

Smoothing Capacitor 7 to 8 years

Test and replace with a new capaci-

tor if necessary.

Relays

— Test and replace if necessary.

Fuse

10 years Replace with a new fuse.

Aluminum Electrolytic Capacitor

on Circuit Board

5 years Te st and replace with a new circuit

board if necessary.

12.1.2 SERVOPACK Inspection

The SERVOPACK contains highly reliable parts and does not require daily inspection. Always

inspection the SERVOPACK at least once a year. Be sure to check user settings prior to opera-

tion because we reset user constants to standard settings when we ship overhauled SERVO-

PACKS.

Table 12.3 Inspection Items

■ Guidelines for Replacing Parts

The following parts are subject to mechanical wear or deterioration over time. To avoid failure,

replace these parts at the frequency indicated in the following table.

Table 12.4 Parts Replacement

Note Operating conditions

Ambient temperature: Annual average of 30°C

Load factor: 80% max.

Operation rate: 20 hours/day max.

Be sure to check user settings prior to operation because Yaskawa resets user constants to facto-

ry settings when shipping overhauled SERVOPACKS.

Loading...

Loading...