YORK INTERNATIONAL

42

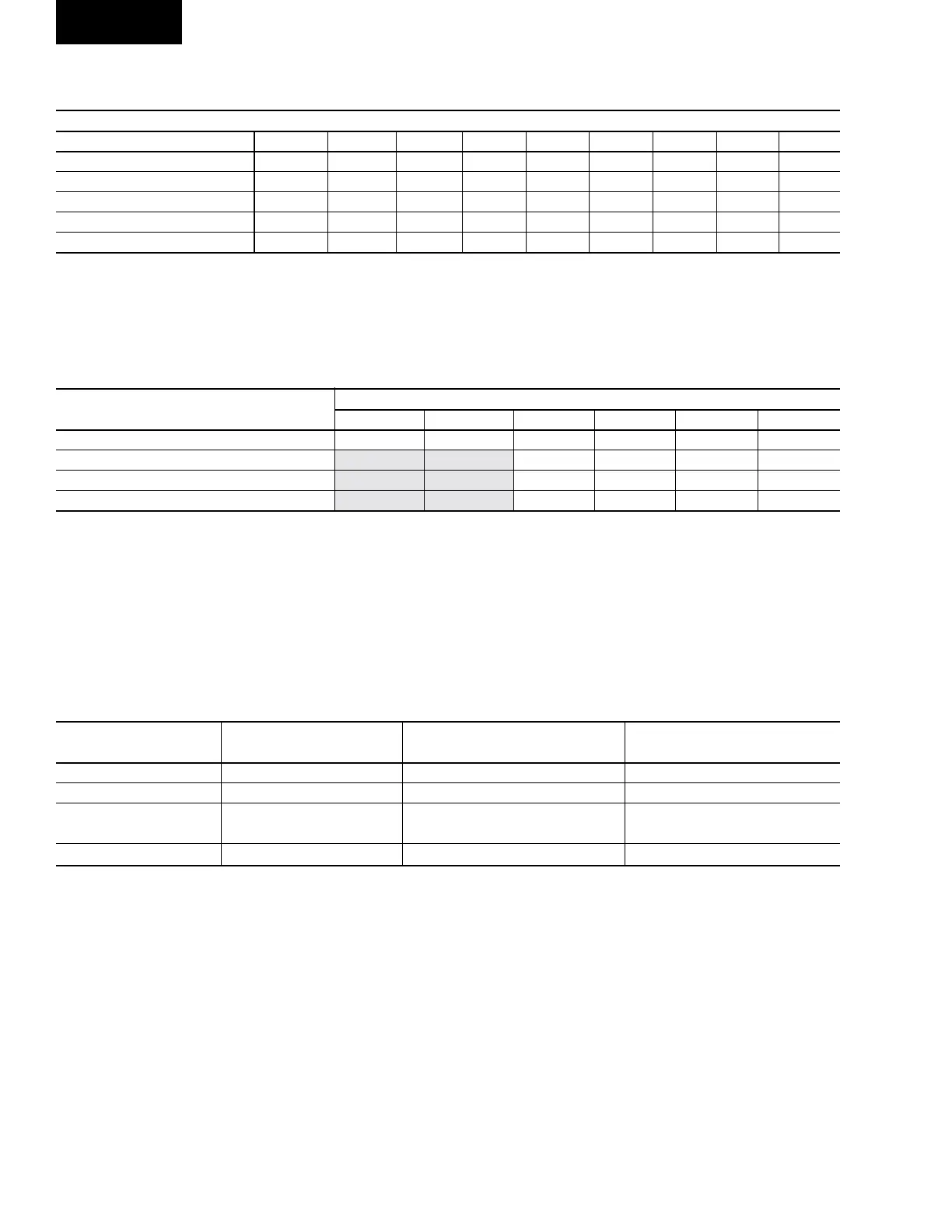

TABLE 8 – FAN BEARING – LUBRICATION INTERVALS

RELUBRICATION SCHEDULE (MONTHS) BALL BEARING PILLOW BLOCKS

SPEED (RPM) 500 1000 1500 2000 2500 3000 3500 4000 4500

SHAFT DIA

1/2" THRU 1-11/16" 6 65332221

1-15/16" THRU 2-7/16" 6 542211/21/41/4

2-11/16" THRU 2-15/16" 5 43211/21/2

3-7/16" THRU 3-15/16" 4 3 2 1 1/2 1/2

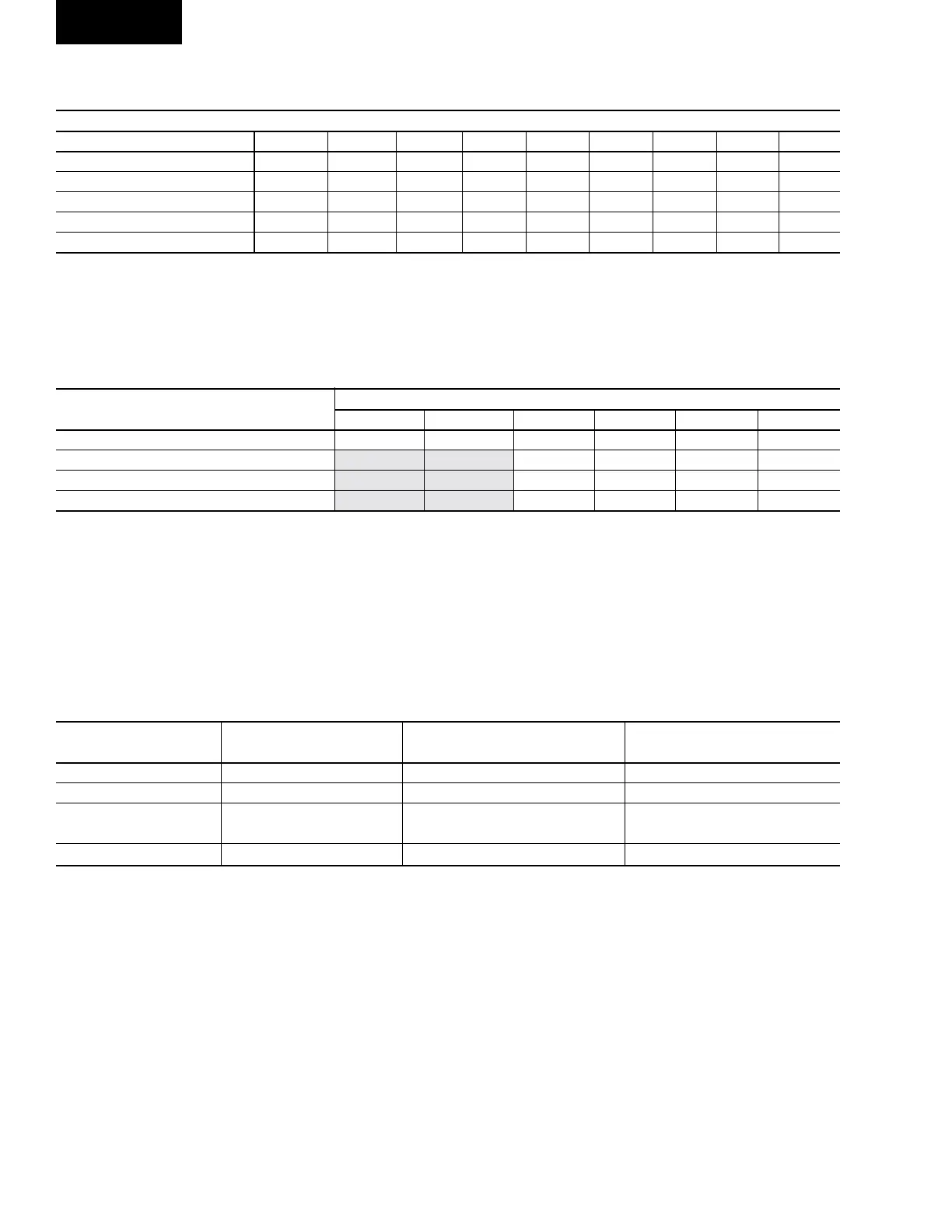

TABLE 9-1 – MOTOR BEARING – LUBRICATION INTERVALS

RATED SPEED - RPM

NEMA / (IEC) FRAM SIZE

10000 6000 3600 1800 1200 900

UP TO 210 INCL. (132)

**

2700 HRS. 5500 HRS. 12000 HRS. 18000 HRS.22000 HRS.

OVER 210 TO 280 INCL. (180) 3600 HRS. 9500 HRS. 15000 HRS. 18000 HRS.

OVER 280 TO 360 INCL. (180) *2200 HRS. 7400 HRS. 12000 HRS. 15000 HRS.

OVER 360 TO 5800 INCL. (180) *2200 HRS. 3500 HRS. 7400 HRS. 10500 HRS.

* Lubrication intervals are for ball bearings. For roller bearings, divide the listed lubrication interval by 2.

** For 6205 and 6806 bearings. For 6807 bearings, consult oil mist lubrication (MN410).

Relubrication interval for 6205 bearing is 1550 hrs. (using grease lubrication).

Relubrication interval for 6806 bearing is 720 hrs. (using grease lubrication).

TABLE 9-2 – MOTOR BEARING – SERVICE CONDITIONS

SEVERITY OF SERVICE

AMBIENT TEMPERATURE ATMOSPHERIC

TYPE OF BEARING

MAXIMUM CONTAMINATION

STANDARD 40°C CLEAN, LITTLE CORROSION DEEP GROOVE BALL BEARING

SEVERE 50°C MODERATE DIRT, CORROSION BALL THRUST, ROLLER

EXTREME

>50°C* OR SEVERE DIRT, ABRASIVE DUST,

ALL BEARINGS

CLASS H INSULATION CORROSION

LOW TEMPERATURE <-30°C**

* Special high temperature grease is recommended (Darmex 707). Note that Darmex 707 grease does not mix with other grease types.

Thoroughly clean bearing and cavity before adding grease.

** Special low temperature grease is recommended (Airoshell 7).

Maintenance

Loading...

Loading...