FORM 100.10-NOM2

59

YORK INTERNATIONAL

SERVICE

TROUBLESHOOTING

An HVAC air system includes the air handling unit and

the entire air circuitry through which air flows. Included

in the system are such components as duct work, fit-

tings, branch duct, dampers, heat exchangers, filters,

sound traps, coils, elbows, registers, grilles, and other

items through which air flows or which offer obstruc-

tion to air flow.

While differences in temperature and humidity may

cause air movement, it may be considered very slight in

comparison to the positive circulation required in an air

conditioning system. To accomplish this air movement,

a fan has two functions to perform.

1. To produce sufficient pressure or head to acceler-

ate the mass of air from a state of rest to the re-

quired velocity, and

2. To produce sufficient pressure to overcome any

resistances to the flow of air.

The determination of these pressures is a very impor-

tant part of troubleshooting an air conditioning system.

The generally accepted standard instrument for mea-

suring these unit pressures is the Pitot Tube. (See Fig-

ures 61 & 62) The Pitot Tube is used in conjunction

with an Inclined Manometer, Magnehelic Gauge, or a

Tube Manometer.

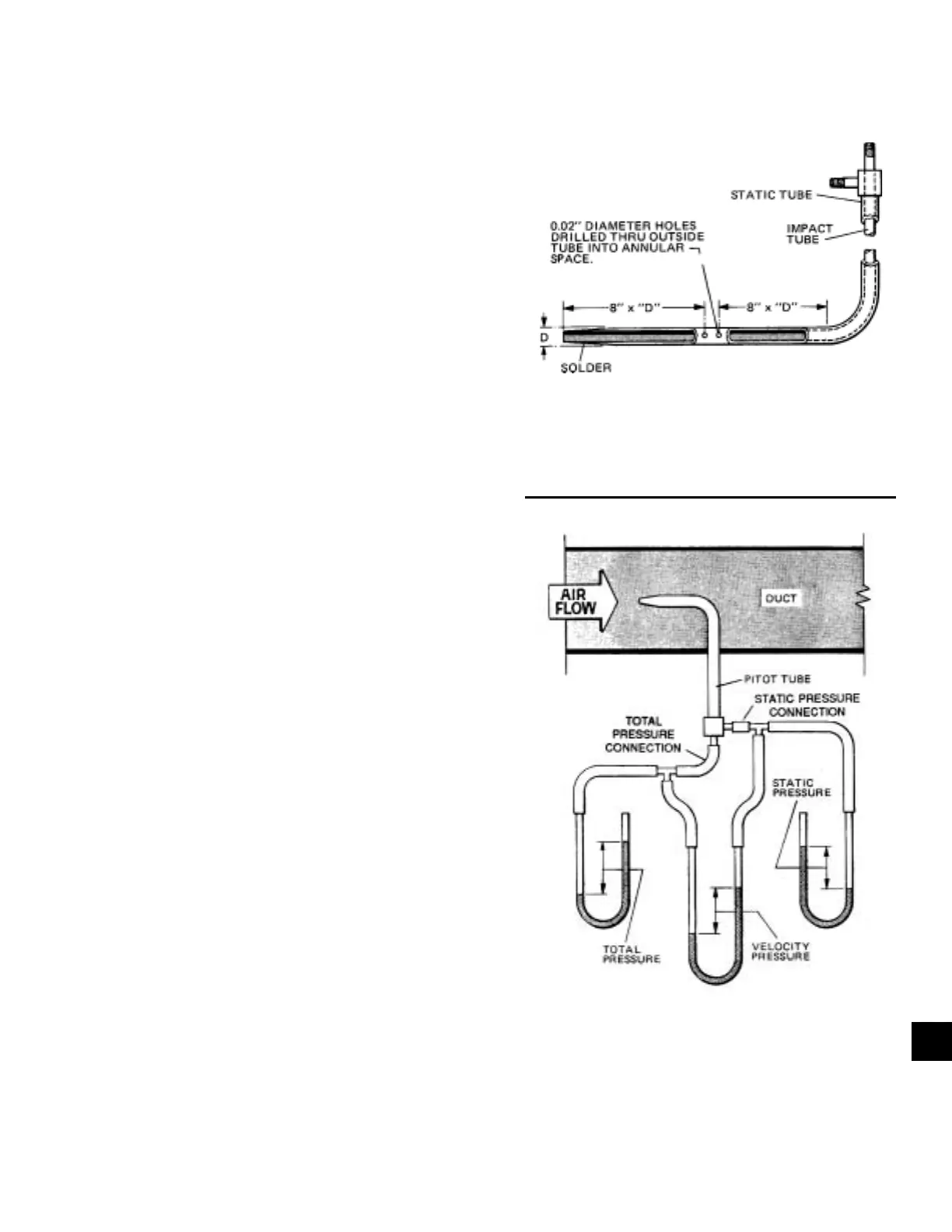

When the Pitot Tube is used in conjunction with these

instruments, one is able to read velocity pressure (Vp),

static pressure (Sp), and total pressure (Tp) within the

system.

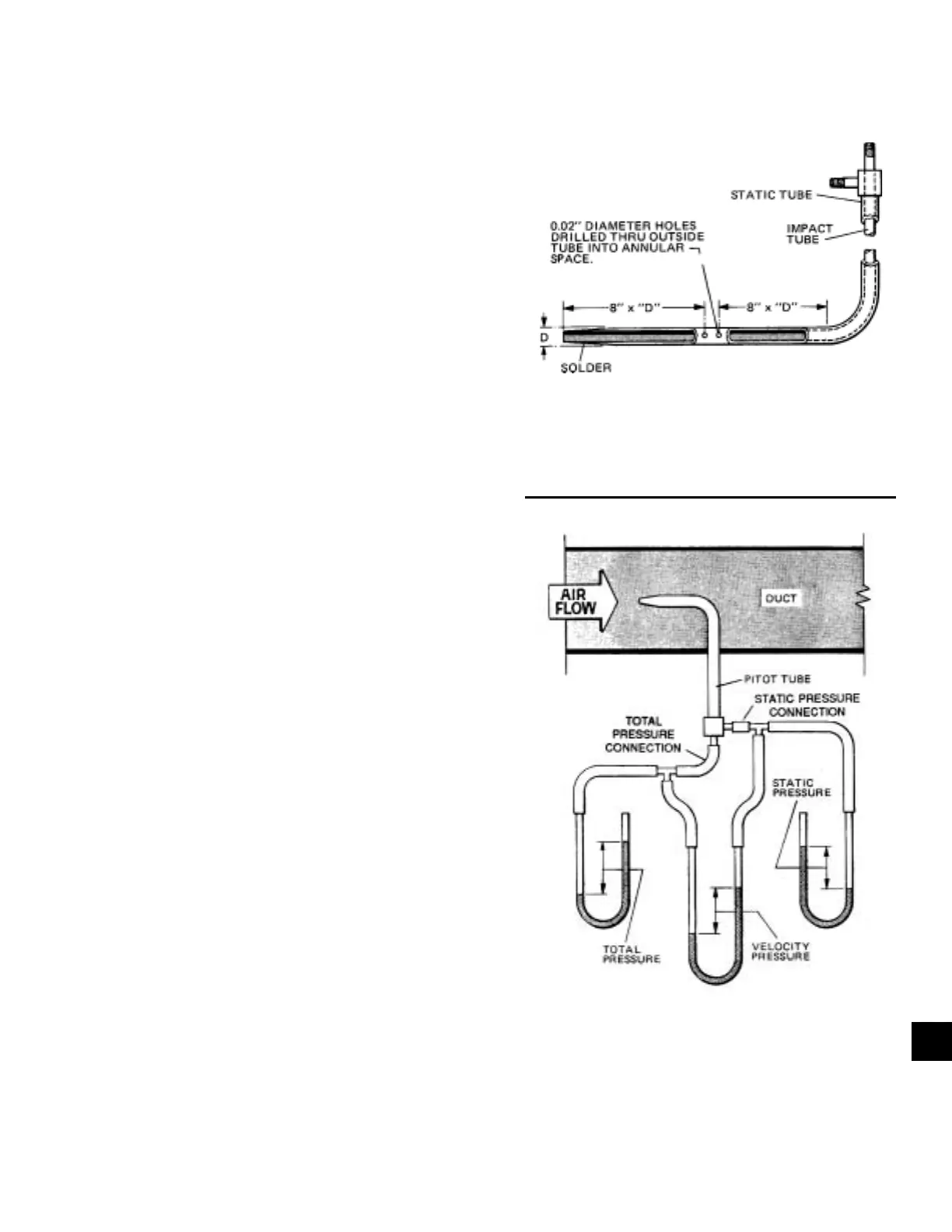

PITOT TUBE

The Pitot consists of an impact tube within a larger

static tube. When the impact tube is pointed directly

into the air stream, the small static pressure holes are

perpendicular to the air stream and are not affected by

air velocity. (See Figure 62)

To read velocity pressure, the total pressure tap at the

end of the pitot tube is connected to one leg of a ma-

nometer and the static pressure tap at the other leg of

the manometer. (See Figure 63)

FIG. 61 – CONSTRUCTION OF PITOT TUBE

FIG. 62 – PITOT TUBE

LD06363

LD06362

5

Loading...

Loading...