earth conductor must be determined in a manner which produces a conductance

equivalent to that which results from the application of this table.

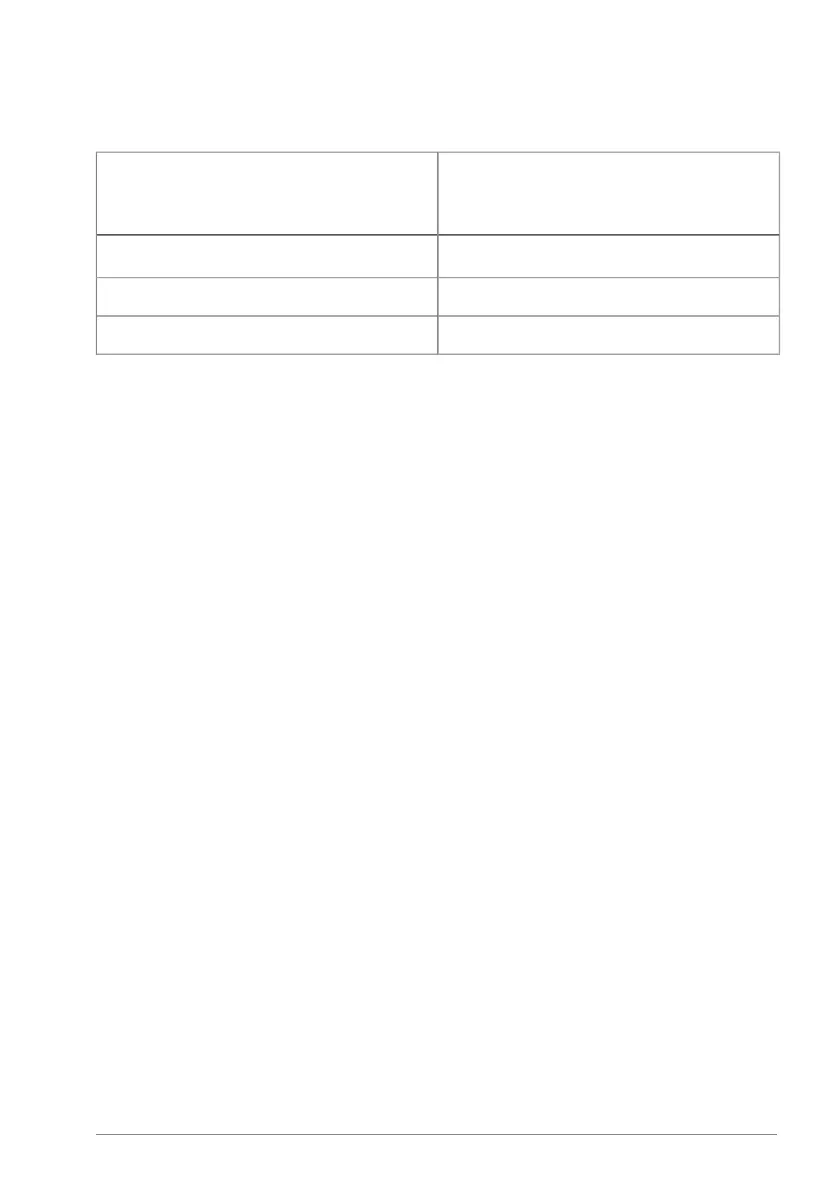

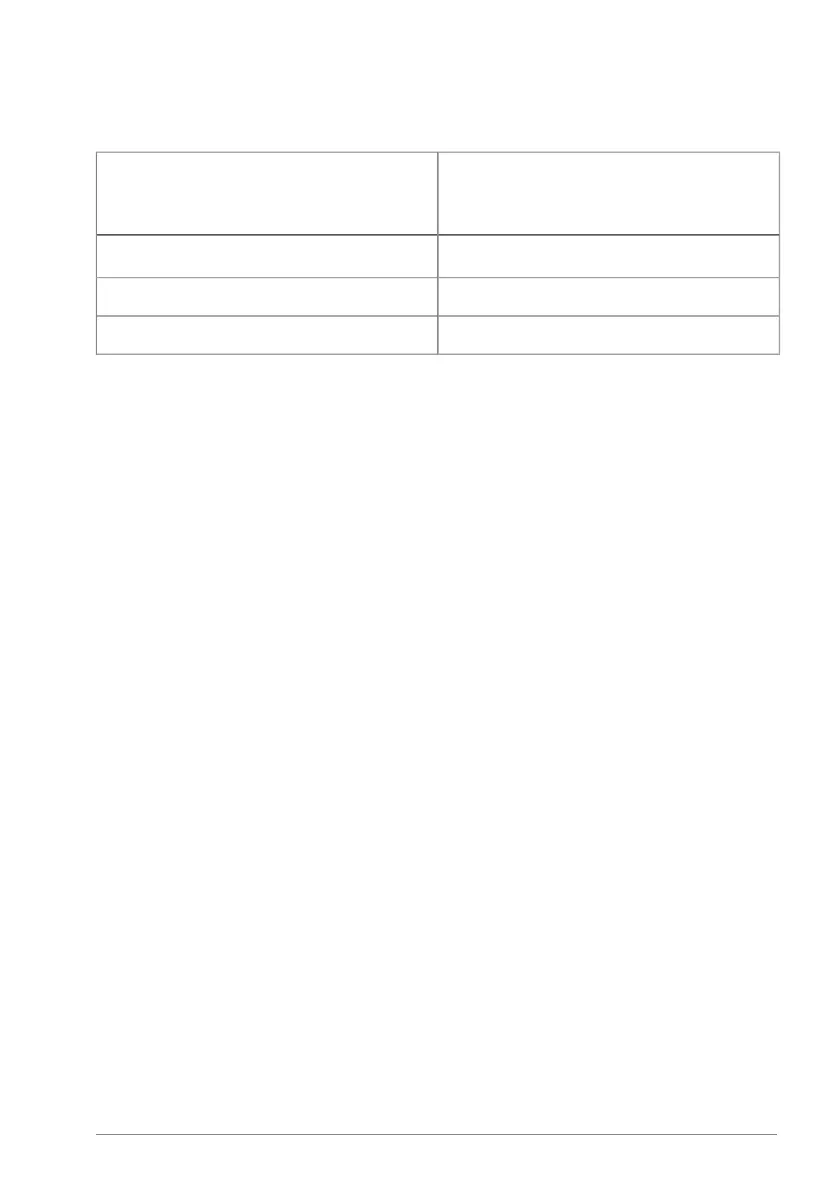

Minimum cross-sectional area of the corres-

ponding protective earth conductor

S

p

(mm

2

)

Cross-sectional area of the phase conduct-

ors

S (mm

2

)

S

1)

S ≤ 16

1616 < S ≤ 35

S/235 < S

1)

For the minimum conductor size in IEC installations, refer to Additional grounding requirements – IEC.

If the protective earth conductor is not part of the input power cable or input

power cable enclosure, the minimum permitted cross-sectional area is:

• 2.5 mm

2

if the conductor is mechanically protected,

or

• 4 mm

2

if the conductor is not mechanically protected. If the equipment is

cord-connected, the protective earth conductor must be the last conductor

to be interrupted if there is a failure in the strain relief mechanism.

■

Additional grounding requirements – IEC

This section gives grounding requirements according to standard IEC/EN 61800-5-1.

Because the normal touch current of the drive is more than 3.5 mA AC or 10 mA DC:

• the minimum size of the protective earth conductor must comply with the

local safety regulations for high protective earth conductor current equipment,

and

• you must use one of these connection methods:

1. a fixed connection and:

• a protective earth conductor with a minimum cross-sectional area of

10 mm

2

Cu or 16 mm

2

Al (as an alternative when aluminum cables are

permitted),

or

• a second protective earth conductor of the same cross-sectional area

as the original protective earth conductor,

or

• a device that automatically disconnects the supply if the protective

earth conductor is damaged.

2. a connection with an industrial connector according to IEC 60309 and a

minimum protective earth conductor cross-section of 2.5 mm

2

as part of

a multi-conductor power cable. Sufficient strain relief must be provided.

Guidelines for planning the electrical installation 51

Loading...

Loading...