Technical data

101

The following parameters can effect on the correct operation of the protection:

• cable length, i.e. the longer the cable the weaker the fuse protection, as the long cable limits the

fault current

• cable size, i.e. the smaller the cable the weaker the fuse protection, as the small cable size limits the

fault current

• transformer size, i.e the smaller the transformer the weaker the fuse protection, as the small

transformer limits the fault current

• transformer impedance, i.e. the higher the z

k

the weaker the fuse protection as high impedance

limits the fault current.

The protection can be improved by installing a bigger supply transformer and/or bigger cables, and in

most cases by selecting aR fuses instead of gG fuses. Selection of smaller fuses improves the

protection, but may also affect the fuse life time and lead to unnecessary operation of the fuses.

In case of any uncertainty regarding the drive protection, please contact your local ABB.

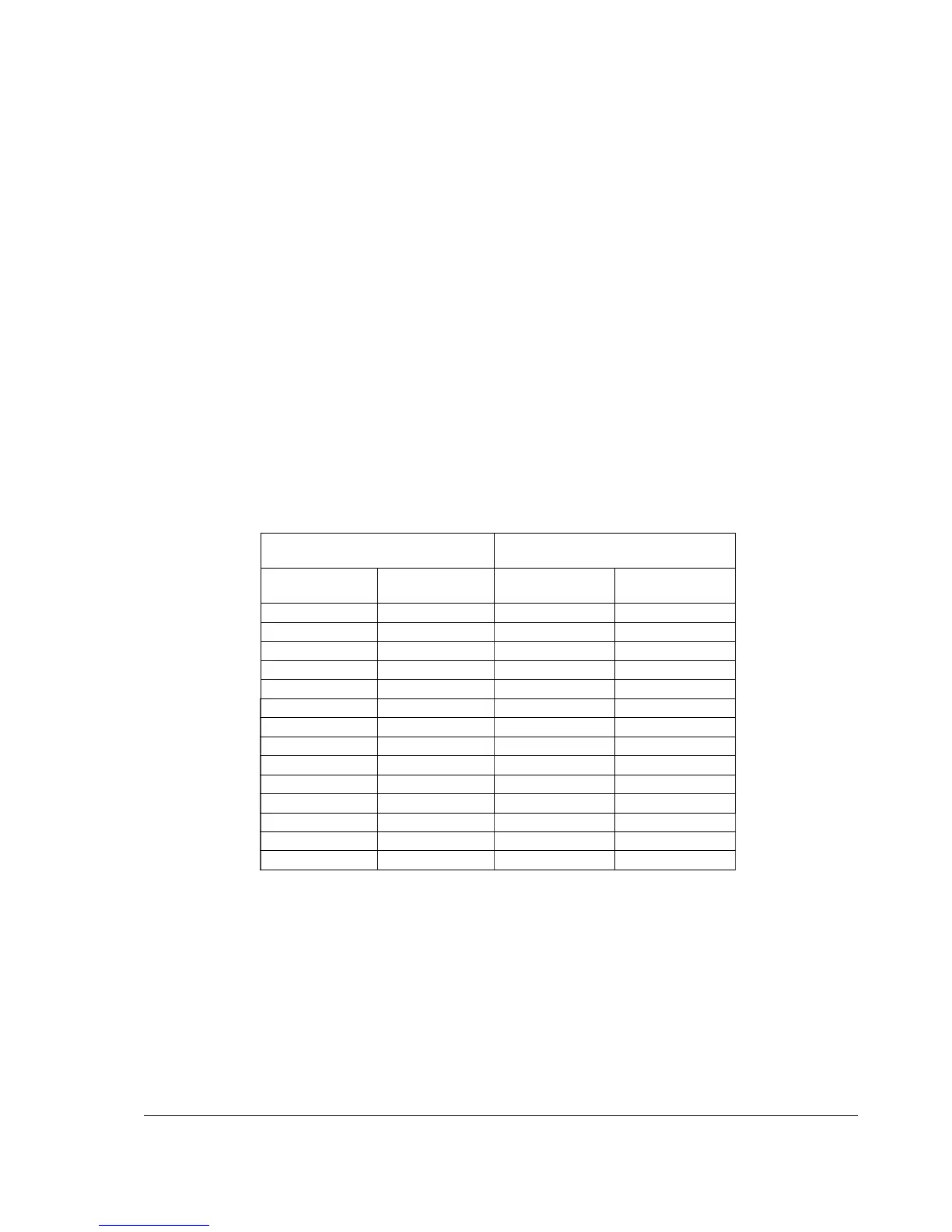

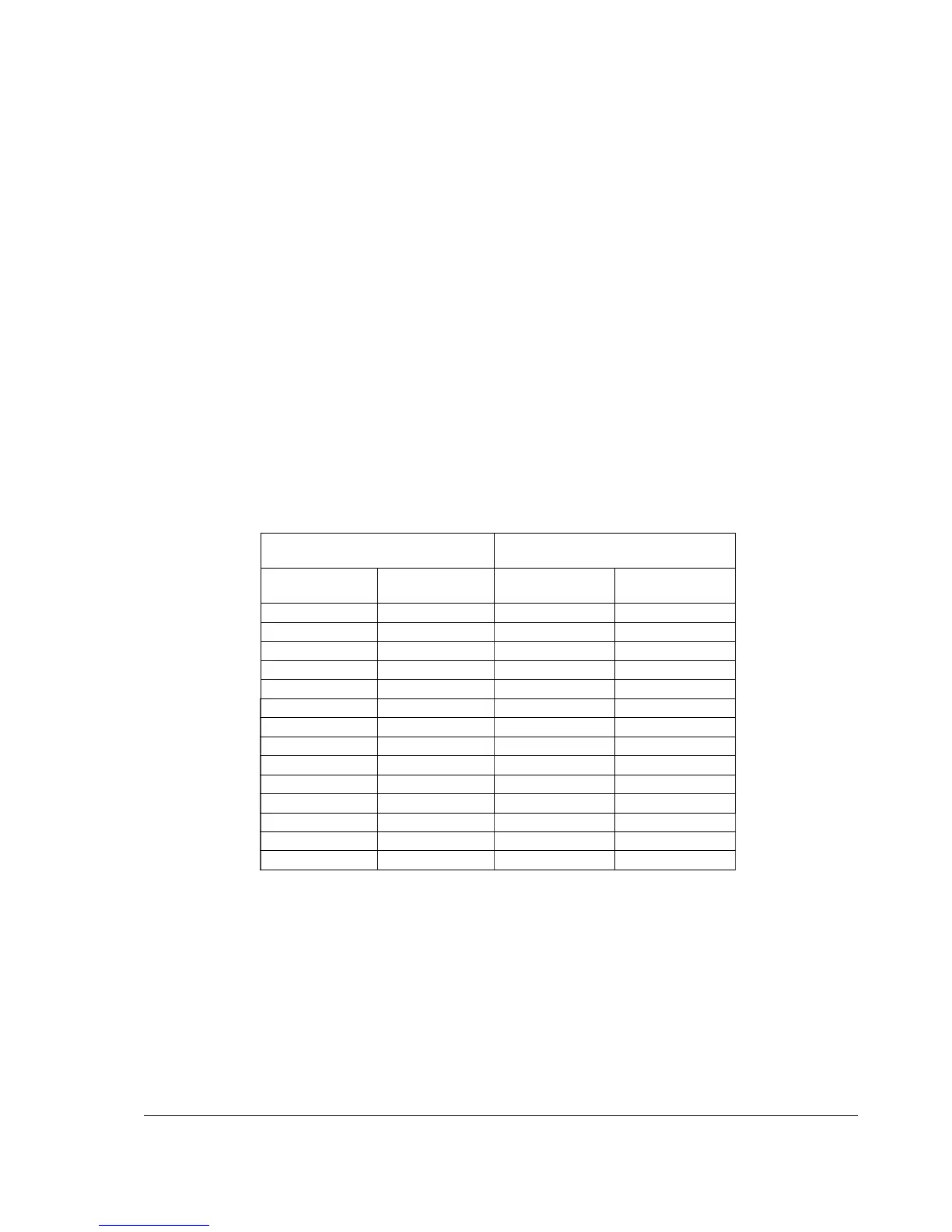

Cable types

The table below gives copper and aluminium cable types for different load currents.

Cable sizing is based on max. 9 cables laid on a cable ladder side by side, ambient

temperature 30 °C, PVC insulation, surface temperature 70 °C (EN 60204-1 and

IEC 60364-5-52/2001). For other conditions, size the cables according to local

safety regulations, appropriate input voltage and the load current of the drive.

Copper cables with concentric

copper shield

Aluminium cables with concentric

copper shield

Max. load current

A

Cable type

mm

2

Max. load current

A

Cable type

mm

2

13 3×1.5 61 3×25

18 3×2.5 69 3×35

24 3×4 83 3×50

30 3×6 107 3×70

42 3×10 130 3×95

56 3×16 151 3×120

71 3×25 174 3×150

88 3×35 199 3×185

107 3×50 235 3×240

137 3×70 274 3 × (3×50)

167 3×95 260 2 × (3×95)

193 3×120

223 3×150

255 3×185

3BFA 01051905 C

Loading...

Loading...