46 Electrical installation

Connecting the control cables

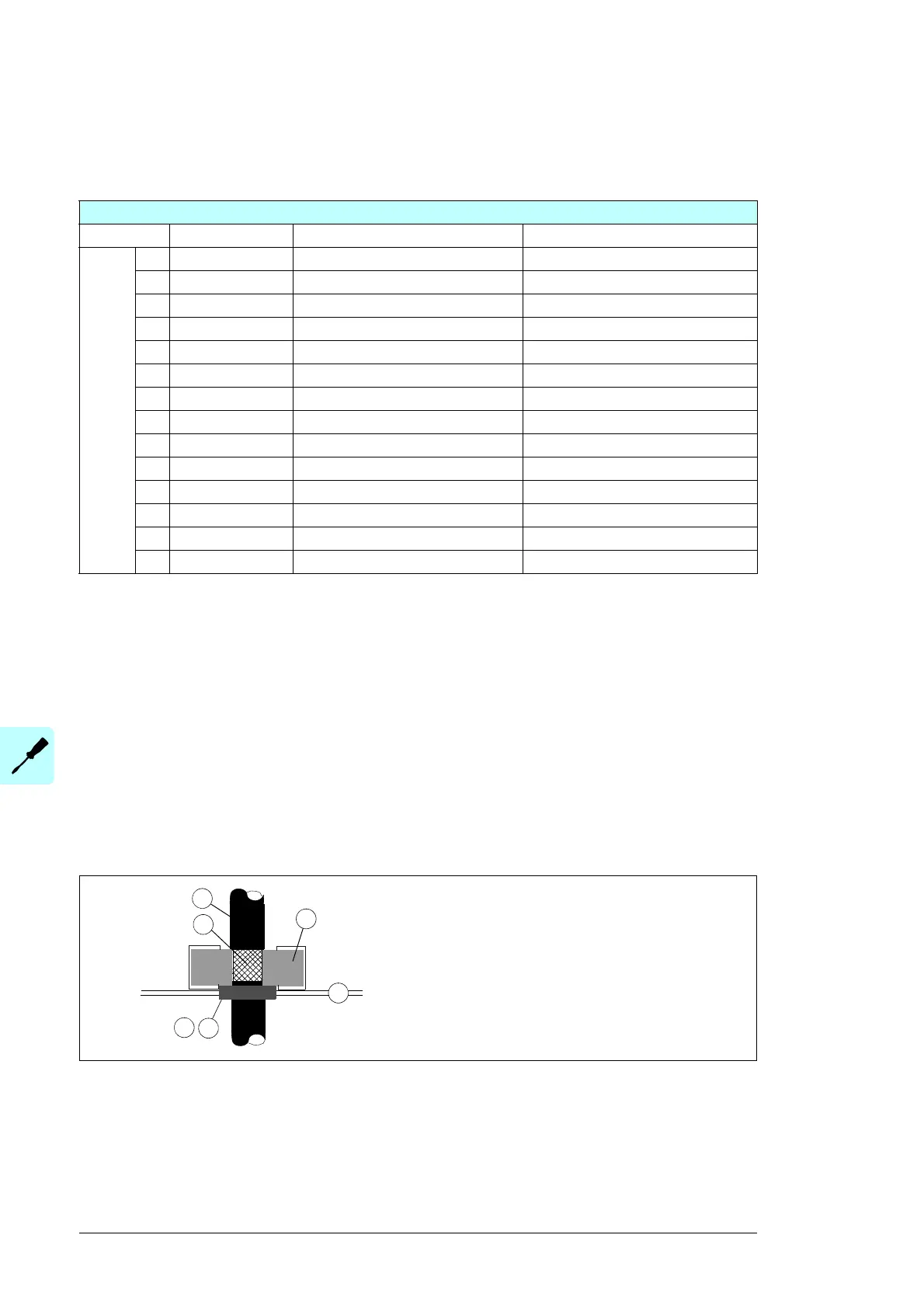

Default I/O connection diagram

You can freely configure the I/O signals with different fault names and reactions. Refer to

the PVS800-57B central inverters firmware manual (3AXD50000048332 [EN]).

Connection procedure

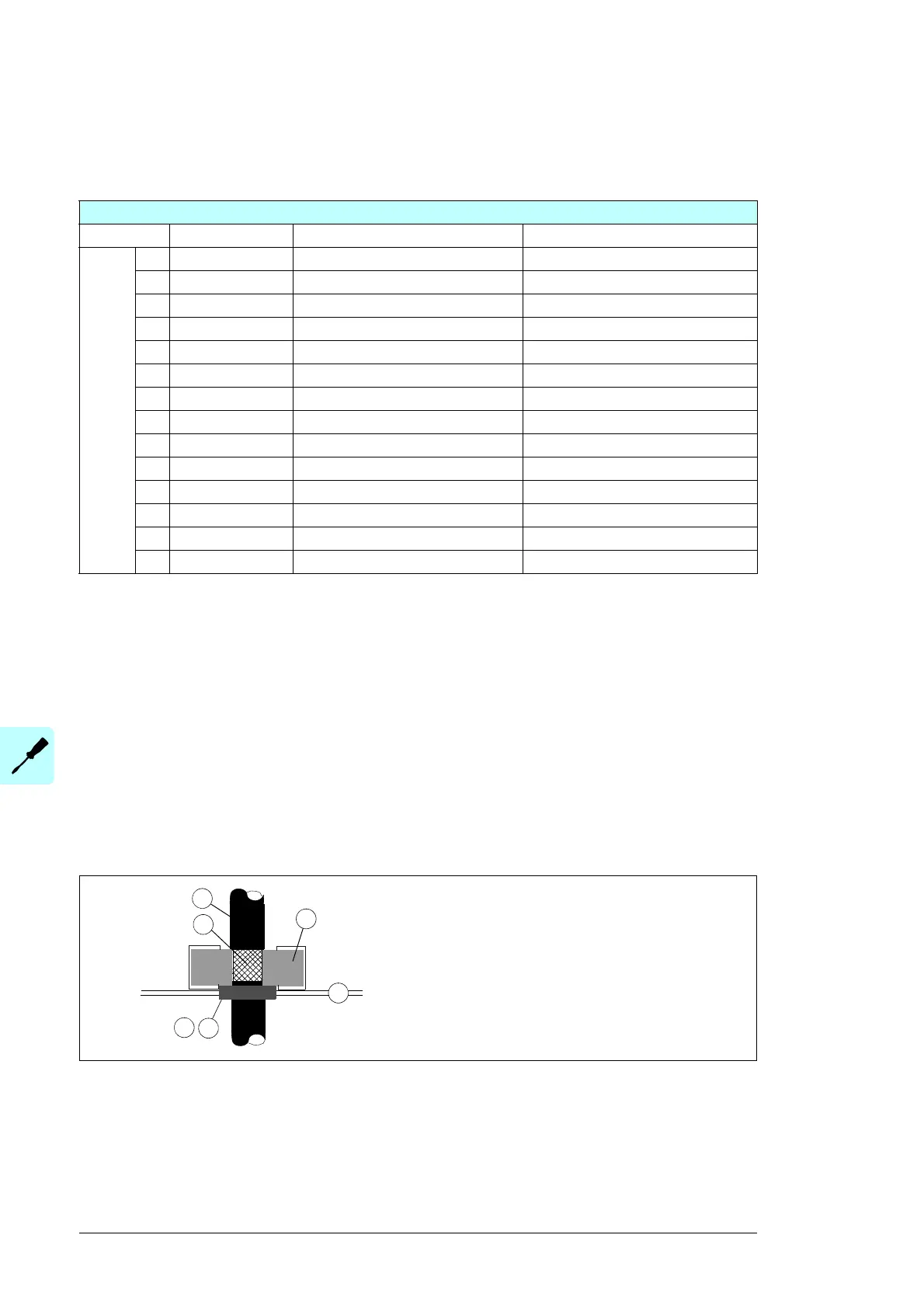

360-degree grounding at the cabinet lead-through for the control cables:

Make sure that a proper environmental seal remains after the installation.

1. Cut adequate holes in the rubber grommets in the lead-through plate.

2. Put the cables through the grommets into the cabinet.

3. Strip the plastic sheath of the cable above the lead-through plate just enough to

ensure proper connection of the bare shield.

Note: If the outer surface of the shield is non-conductive:

• Cut the shield at the midpoint of the bare part. Do not cut the conductors or the

grounding wire (if present).

• Turn the shield inside out to expose its conductive surface.

• Cover the turned shield and the stripped cable with copper foil to make the shielding

continuous.

Control I/O connection diagram

Terminal Type Rating Functionality

X2

+ +24 V DC +24 V DC Power distribution

- 0 V DC 0 V DC Power distribution

1 User DI1 24 V DC

2 User DI2 24 V DC

3 User DI3 24 V DC

4 User DI4 24 V DC

5 User DI5 24 V DC

6 User DI6 24 V DC

7 User DI7 24 V DC

8 User RO1 24 V DC

9User AI2 +

10 User AI2 4–20 mA -

11 User AI3 +

12 User AI3 4–20 mA -

a

1

3

Side view of the cable lead-through

a) Grommet

b) EMI conductive cushion

c) Lead-through plate

c

b

2

Loading...

Loading...