60 Maintenance

Recommended annual maintenance actions by the user

ABB recommends that you do these annual inspections to ensure the highest reliability

and optimum performance of the inverter.

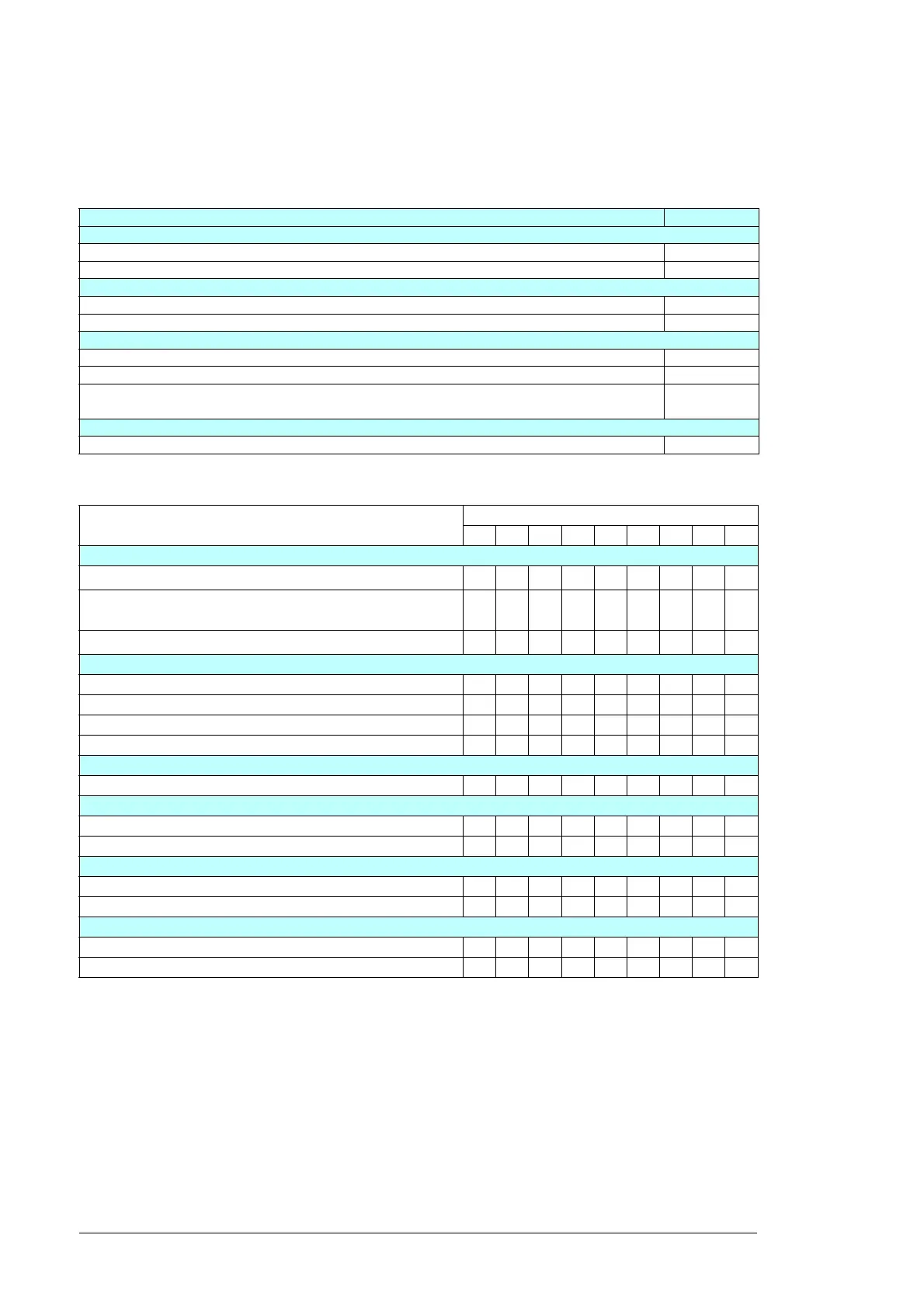

Recommended maintenance intervals

1) Always when inverter module is replaced, check the cleanliness and condition of power connection and heat

sink. Cleaning if needed.

2) Check the tightness of the main circuit terminals during commissioning. See the recommended tightness in

the Hardware manual. If the inverter installation conditions require, check the tightness more often. Obey the

local regulations.

Target / task Action

Connections and environment

Environment check I

Cabinet door filters IP41 R

Spare parts

Spare parts I

DC circuit capacitors reforming, spare modules and spare capacitors P

Inspections by the user

IP41 air inlet and outlet grills I

Inspection of dustiness, corrosion, and temperature inside the cabinet. Cleaning, if needed. I

Overall cleanliness of inverter (e.g. cabinet door sealings, function of cooling fans, main circuit

terminals)

I

Other

Air circuit breaker maintenance I

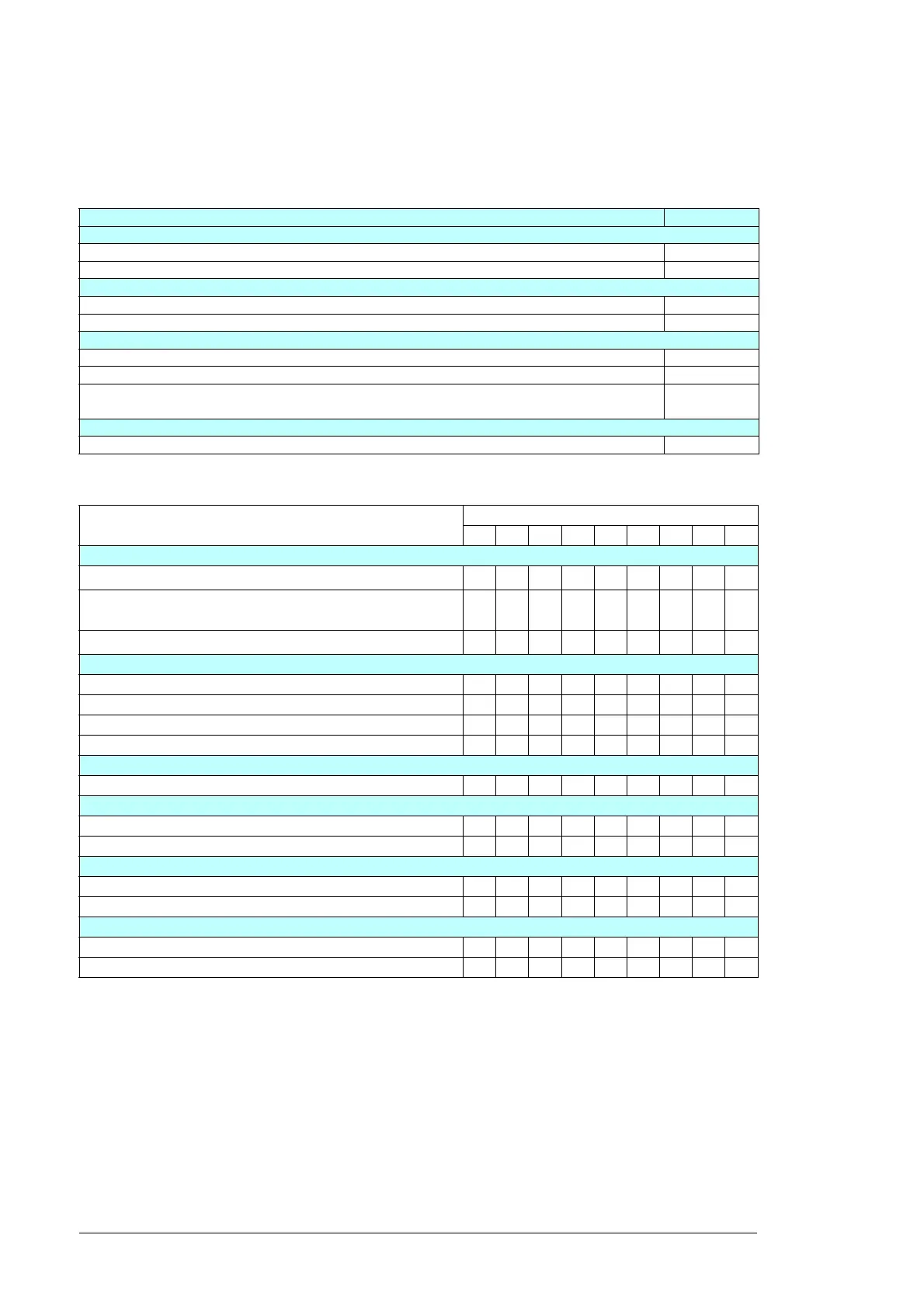

Component Years from start-up

1 3 6 9 1215182124

Connections and environment

Heat sink cleaning

(1

IIIIIIII

Cleanliness of power connections of the inverter module.

Clean if necessary.

(1

IIIIIIII

Tightness of the AC and DC terminals

(2

III

Main cooling fans and control

Main cooling fan, inverter unit R R

BFPS module internal power supply boards R R

Cooling fan, LCL-filter unit R R

Cooling fan of R8i inverter unit PCBs R R

Cabinet cooling fans

Cabinet cooling fans R R

Inverter unit

BINT, BGDR, BDPS module internal circuit boards R R

Flat ribbon cables (module internal circuit boards) R R

Common, control panel and control unit batteries

BCU control unit battery (Real-time clock) RRRR

Control panel battery (Real-time clock) R R

Buffers and power supplies

Auxiliary power supplies R R

Auxiliary buffers R R

3AXD10000605550

Loading...

Loading...