FOR MODELS: JGI, JGM, JGN, JGP AND JGQ SECTION 5 - MAINTENANCE

PAGE 5-32 9/08

readings, taken without the use of feelers are to be used for acceptance. Copy Table 5-3 and

record calculations and readings.

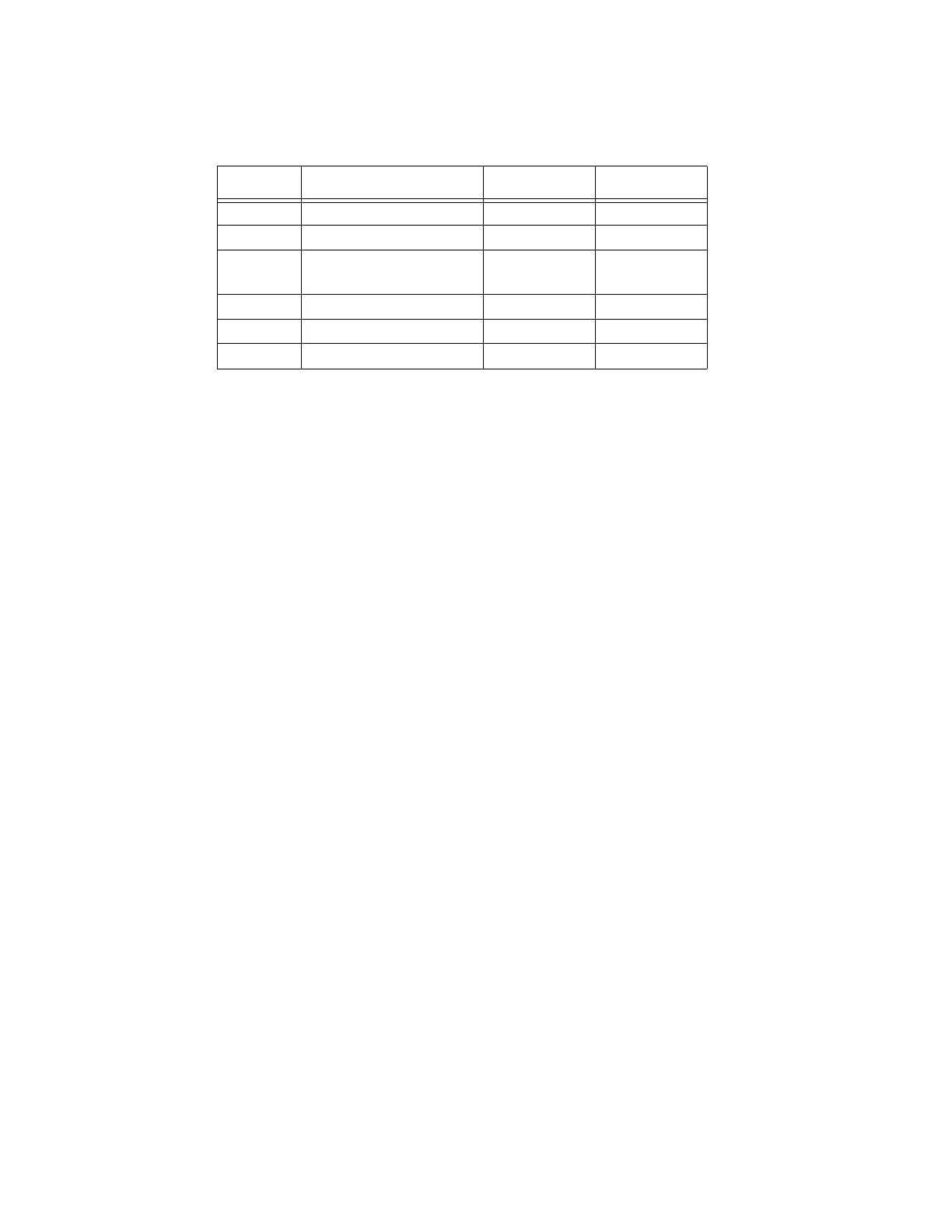

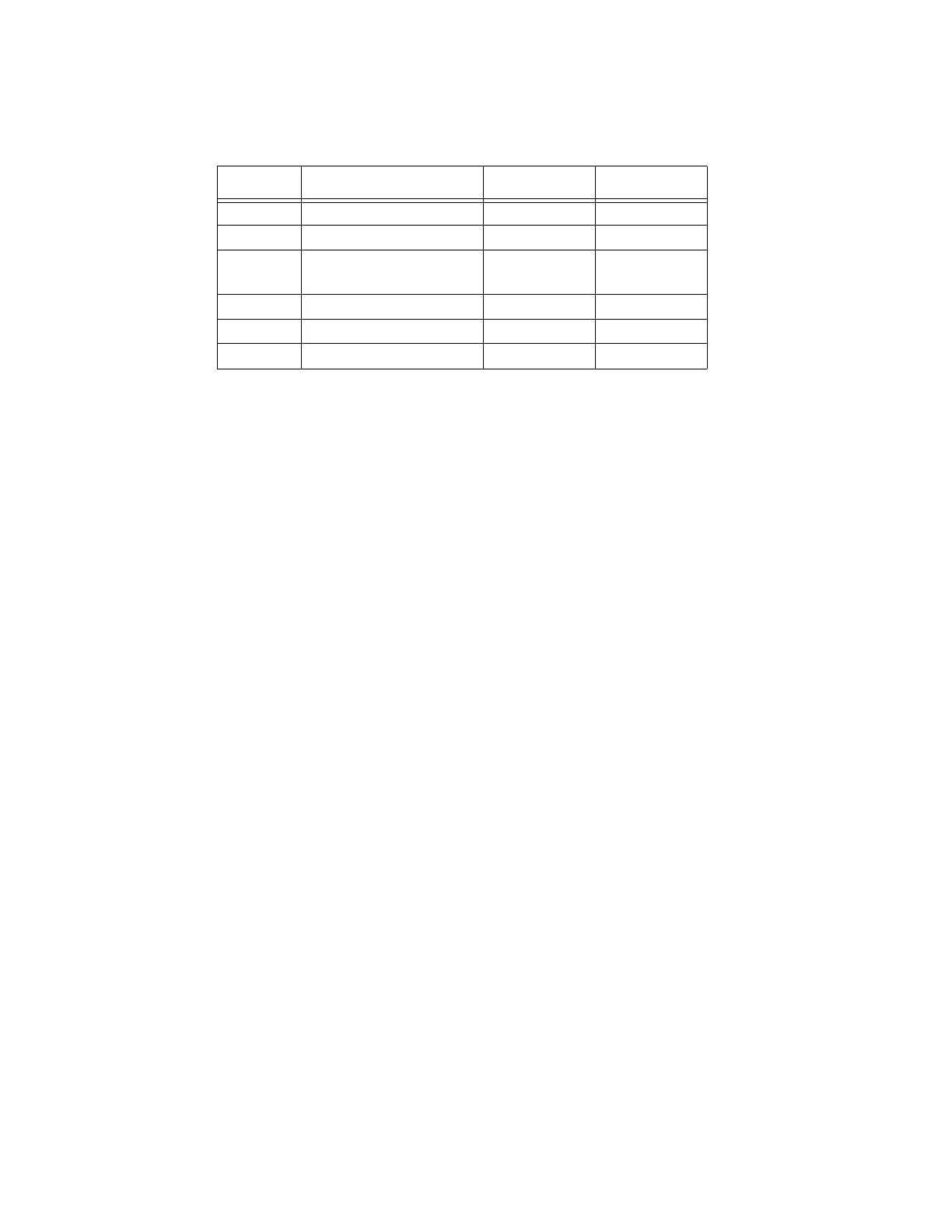

TABLE 5-3 FEELER THICKNESS TO CORRECT FOR PISTON WEIGHT

If readings are not within acceptable limits after replacing worn parts and correcting any pip-

ing misalignment, the piston rod assembly should be replaced.

Piston Rings

JGI, JGM, JGP, JGN and JGQ cylinders use one-piece angle cut filled Teflon piston rings.

Determining Ring Wear:

Ariel recommends replacing rings when the end gap has increased three times the new

dimension. To measure the end gaps, insert the rings in the cylinders without pistons. (See

Table 1-7 on page 1-12 or Table 1-9 on page 1-14 for new end gap dimensions.)

Removal:

See paragraph 3. at “Piston and Rod” on page 5-27 for piston ring removal.

Piston Rings - Installation

1. Place the rings over the grooves in the piston. Compress the Teflon one-piece

rings by hand.

2. With the rings fully compressed in the grooves, insert the rod and piston into the

cylinder

. Make sure the rings stay in place while inserting the piston and rod.

NOTE: RING GAPS ARE TO BE STAGGERED AROUND THE PISTON, RATHER THAN

IN LINE.

3. Follow the steps under “Piston and Rod - Installation” on p

age 5-30.

Wear Bands

1-3/4JG-FS-HE and 1-3/4SG-FS-HE cylinder class pistons use a one-piece angle cut Teflon

wear band.

LINE THROW NUMBER: 1 2

1. Top Feeler Clearance

2. Line 1 (Divided by 2)

3.

Line 2 - 0.003 in.

(-0.08 mm)

- 0.003 in.

(-0.08 mm)

- 0.003 in.

(-0.08 mm)

4. Bottom Feeler Thickness

5. Vertical - Piston @ CE 0 0

6. Vertical - Piston @ HE

Loading...

Loading...