• Unloading valve (UV) is opened by the pressure in the oil separator vessel. The pressure from the oil

separator vessel is released into atmosphere through the unloader (UA).

• The pressure in the oil separator vessel stabilises at low value. A reduced amount of air is compressed to

guarantee a minimal pressure, required for lubrication during unloaded operation.

Air output is stopped (0%), the compressor runs unloaded.

Loaded operation

When the net pressure is below the loading pressure, solenoid valve (Y1) is energised.

• Control pressure is fed from the oil separator vessel via solenoid valve (Y1) to loading plunger (LP) and

unloading valve (UV).

• Unloading valve (UV) closes the air blow-off opening. Loading plunger (LP) moves downwards and

causes inlet valve (IV) to open fully.

Air delivery is resumed (100%), the compressor runs loaded.

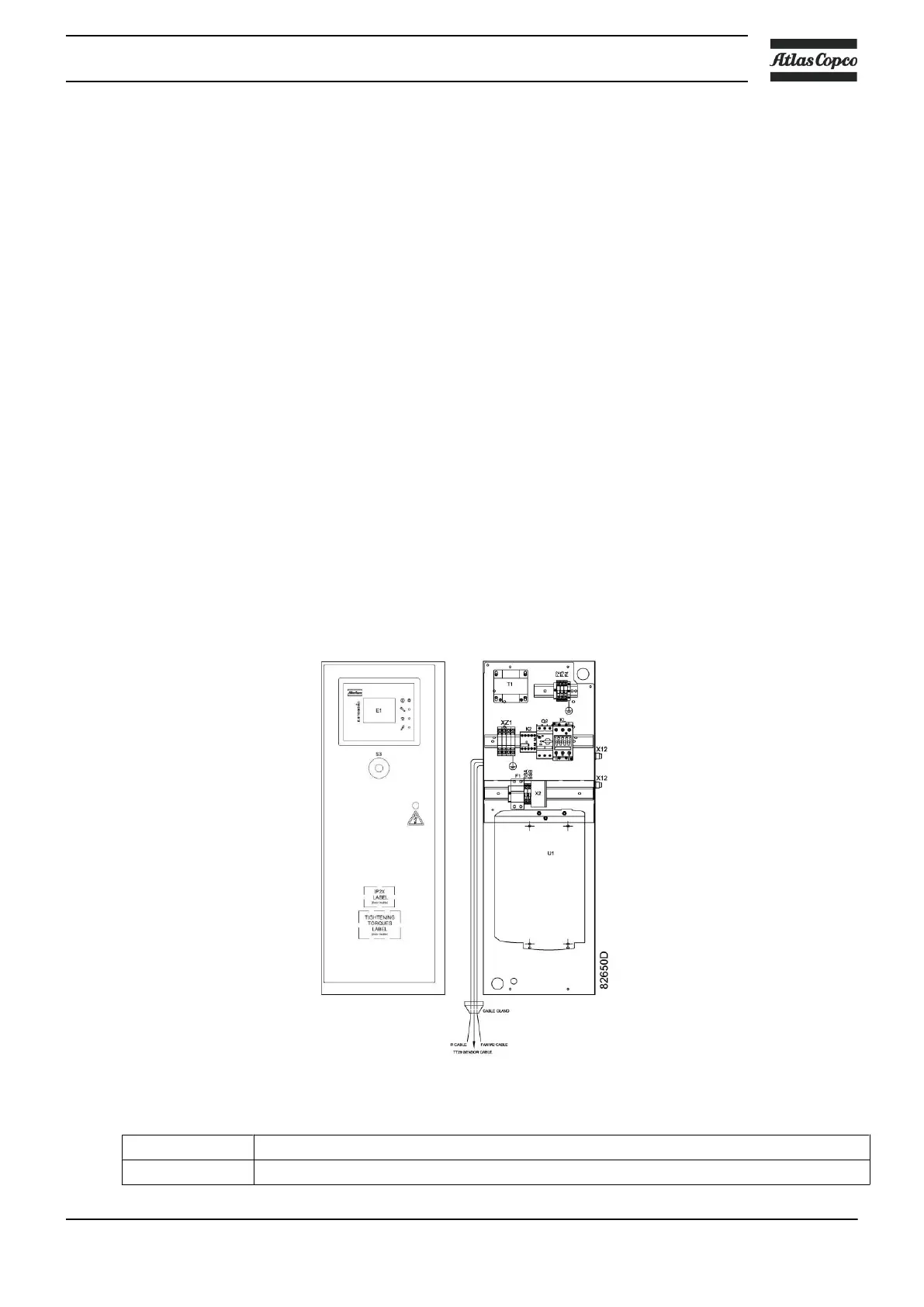

2.7 Electrical system

General

Also consult sections Electrical diagram and Electrical connections.

Components

Compressor cubicle

Reference Description

T1 Transformer

Instruction book

2920 7104 10 15

Loading...

Loading...