In order to ensure that the machine remains within

the stated vibration level values, the following checks

must be performed:

Maintenance routines:

♦

Check and replenish fuel.

♦

Check and replenish lube oil.

♦

Check for oil leaks.

♦

Clean and refit air filter.

♦

Check the tightness of all nuts and bolts.

♦

Keep the machine clean.

♦

Check and clean the engine's cooling flanges. See

the engine manual for more information.

♦

Check the engine's air filter indicator. See the

engine manual for more information.

♦

Check that the controls are not damaged or do

not jam.

Checking the engine

1. Stop the engine and wait for a few minutes. The

machine must be horizontal.

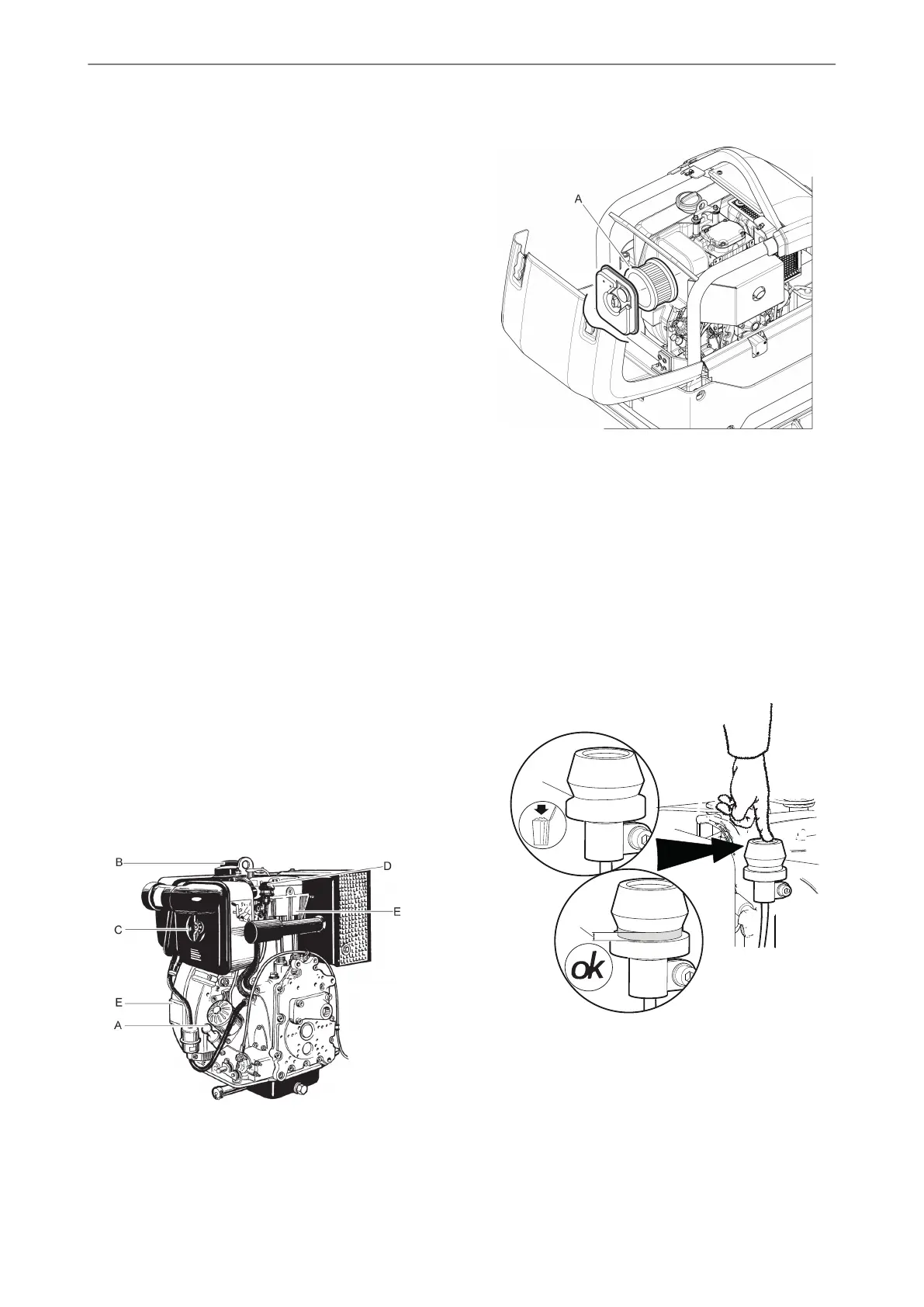

2. Clean around the dipstick (A).

3. Check the oil level with the dipstick (A), fill up if

necessary.

4. Check the fuel level (B).

5. Check for oil leakage.

6. Check the air filter (C) replace if necessary.

7. Check the air filter indicator (D).

8. Check the engine's cooling system (E) and

cooling flanges. Clean if necessary.

Checking the air filter

♦

Check the engine air filter (A).

♦

If the engine air filter is contaminated by dry dust,

tap it against the palm of the hand until all loose

dust is dislodged.

♦

If the engine air filter is wet or oily, replaced it by

a new filter.

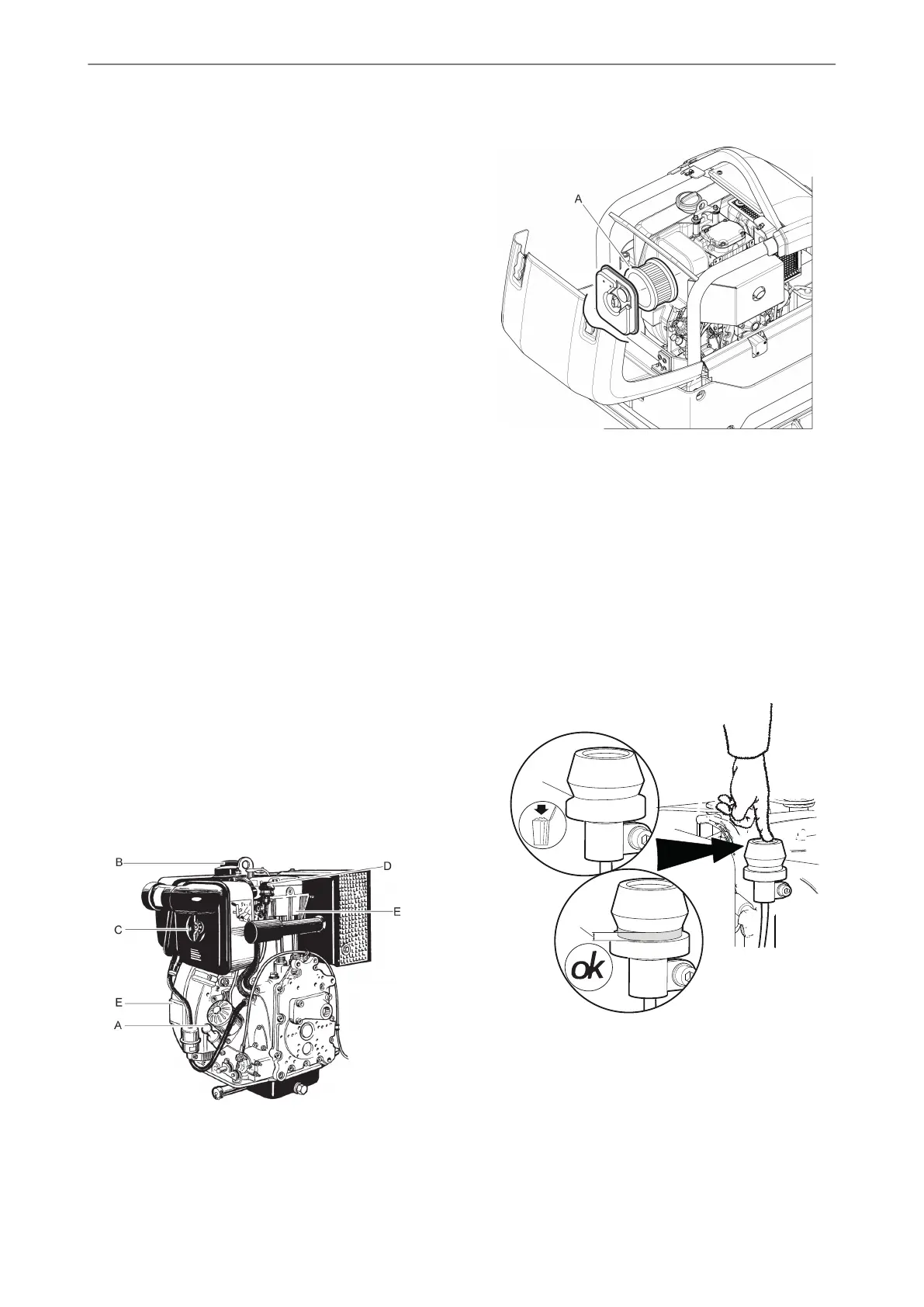

Air filter indicator

NOTICE Each time the engine is started, run the

machine at full throttle and check the filter indicator

if the filter is clogged.

1. Press down the air filter indicator (B).

2. If the air filter indicator (B) goes up again so the

green mark (C) is visible, the air filter is OK do

not need any maintenance.

If the air filter indicator (B) stays down so the

green mark (C) is hidden, the air filter needs to

be cleaned or changed.

See the engine manual for more information.

© 2016 Construction Tools EOOD | No. 9800 1721 01 | 2016-04-07

Original instructions

26

LG 504Safety and operating instructions

Loading...

Loading...