- 31 -

STARTING/STOPPING

BEFORE STARTING

1. Before initial start-up, prepare battery for

operation if not already done. See section Battery

care.

2. With the compressor standing level, check the

level of the engine oil. Add oil, if necessary, up to

the upper mark on the dipstick. Consult the

Engine Operation Manual for the type and

viscosity grade of the engine oil.

3. Check the level of the compressor oil. See section

Compressor regulating system. The pointer of

the oil level gauge (OLG) should register in the

green range. Add oil if necessary. See section Oil

specifications for the oil to be used.

4. Check that the fuel tank contains sufficient fuel.

Top up, if necessary. Consult the Engine

Operation Manual for the type of fuel.

5. Drain any water and sediment from the fuel filter

until clean fuel flows from the drain cock.

6. Press vacuator valves (VV) of the air filters to

remove dust.

7. Check the air filter vacuum indicators (VI). If the

yellow piston reaches the red marked service

range, replace the filter element. Reset the

indicator by pushing the reset button.

8. Open air outlet valve to allow air flow to the

atmosphere.

Before removing the oil filler plug (FP),

ensure that the pressure is released by

opening an air outlet valve.

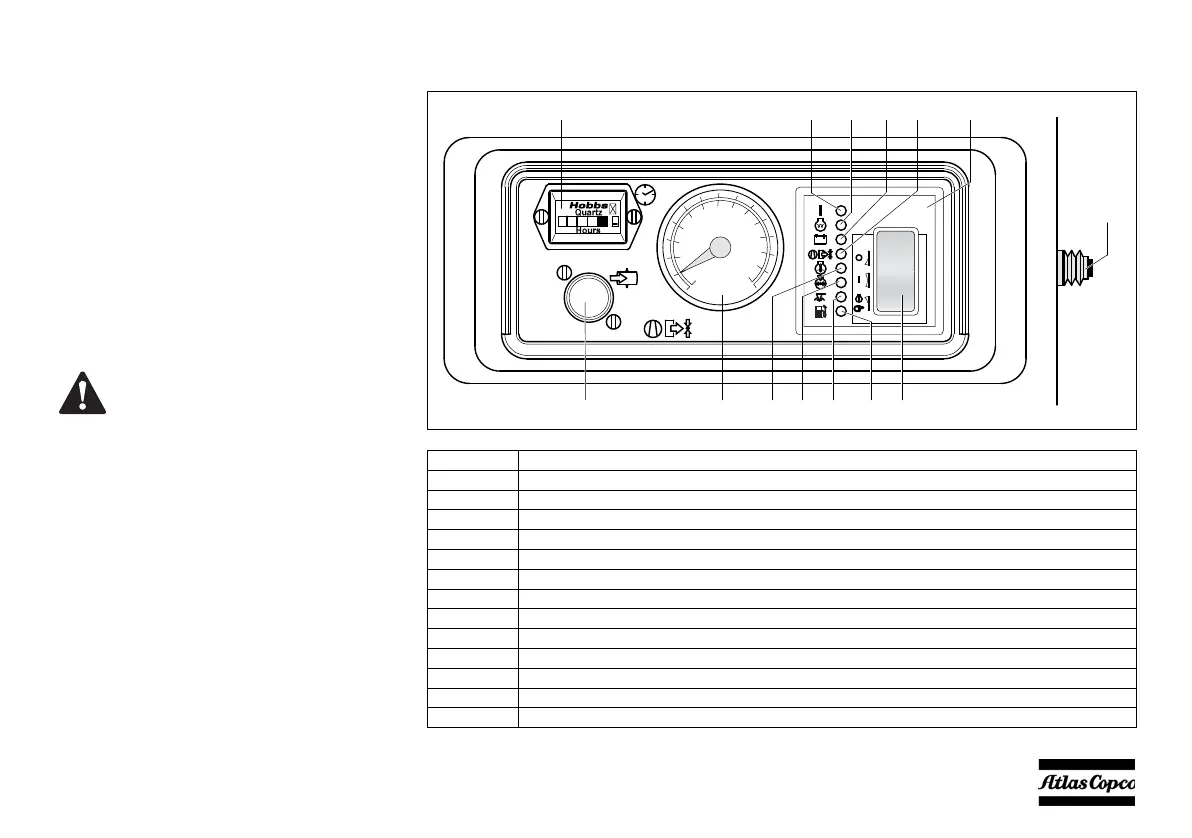

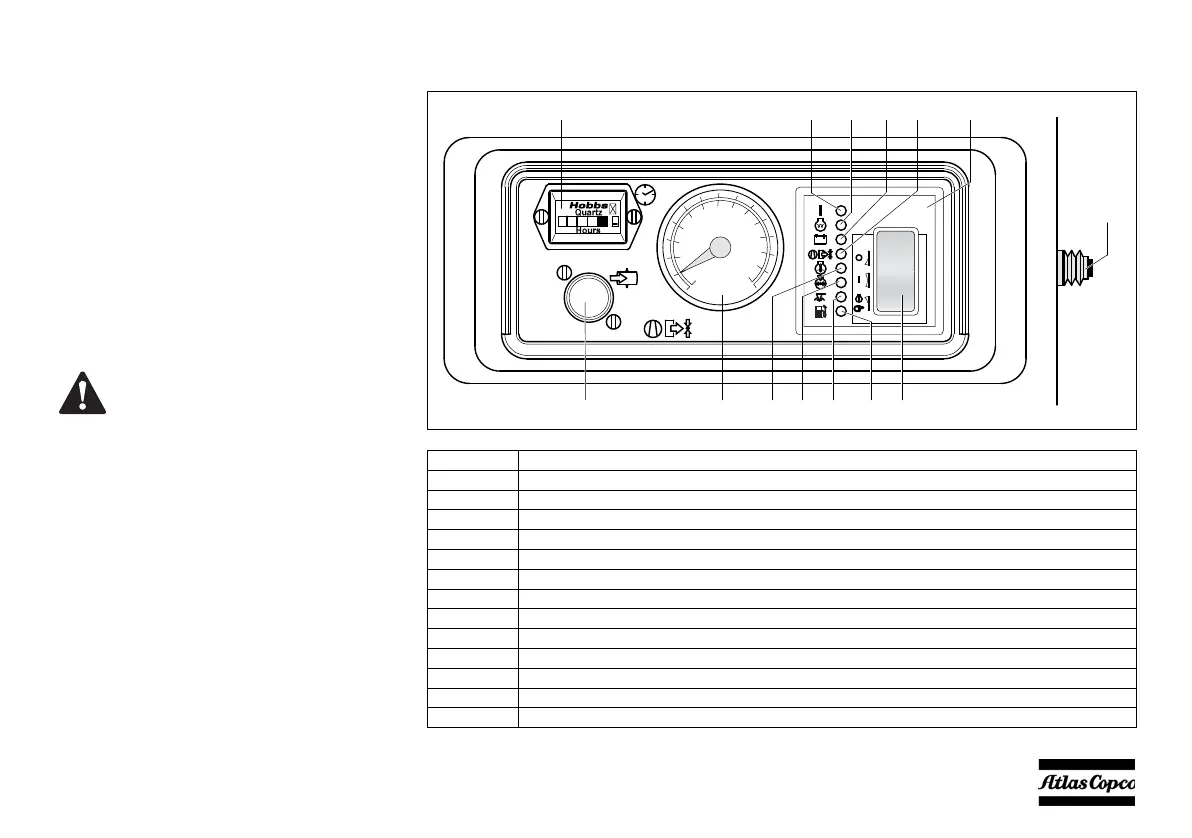

CONTROL PANEL

P1 Hourmeter

F1 Circuit Breaker Button

PG Working pressure gauge

LV Loading Valve

N4 Control Module

S Start/Stop Button

H1 LED (green) Fuel ON

H2 LED (green) Preheat (option)

H3 LED (red) Charge Indication

H4 LED (red) Compressor Outlet Temperature

H5 LED (red) Engine Oil Temperature

H6 LED (red) Engine Oil Pressure

H7 LED (red) Low Coolant

H8 LED (red) Low Fuel

(PG)(LV) (H5) (H6) (H7) (S)

(F1)

0

000

(H1) (H2) (H3) (H4) (N4)(P1)

(H8)

DD6.book Page 31 Monday, November 10, 2014 11:25 AM

Loading...

Loading...