Do you have a question about the Beckhoff BK3120 and is the answer not in the manual?

| Product Type | Bus Coupler |

|---|---|

| Product Name | BK3120 |

| Protection Class | IP20 |

| Dimensions | 100 x 75 x 22.5 mm |

| Weight | 200 g |

| Power Supply | 24 V DC |

| Current Consumption | Typically 70 mA |

| Electrical Isolation | 500 V |

| Operating Temperature | 0 °C to +55 °C |

| Storage Temperature | -25…+85 °C |

| Relative Humidity | 95 %, no condensation |

Outlines safety regulations, exclusion of liability, and describes instruction symbols used.

Provides instructions to prevent damage from electrostatic discharge during handling.

Describes the procedure for mounting Bus Couplers and terminals on a DIN rail.

Explains different connection system options for Bus Terminals.

Provides instructions and guidelines for wiring Bus Terminals.

Details the power supply requirements and connections for Bus Couplers and terminals.

Explains PROFIBUS connection types, pin assignments, and cabling requirements.

Outlines special conditions for using components in potentially explosive areas.

Specifies conditions for ET components in potentially explosive areas.

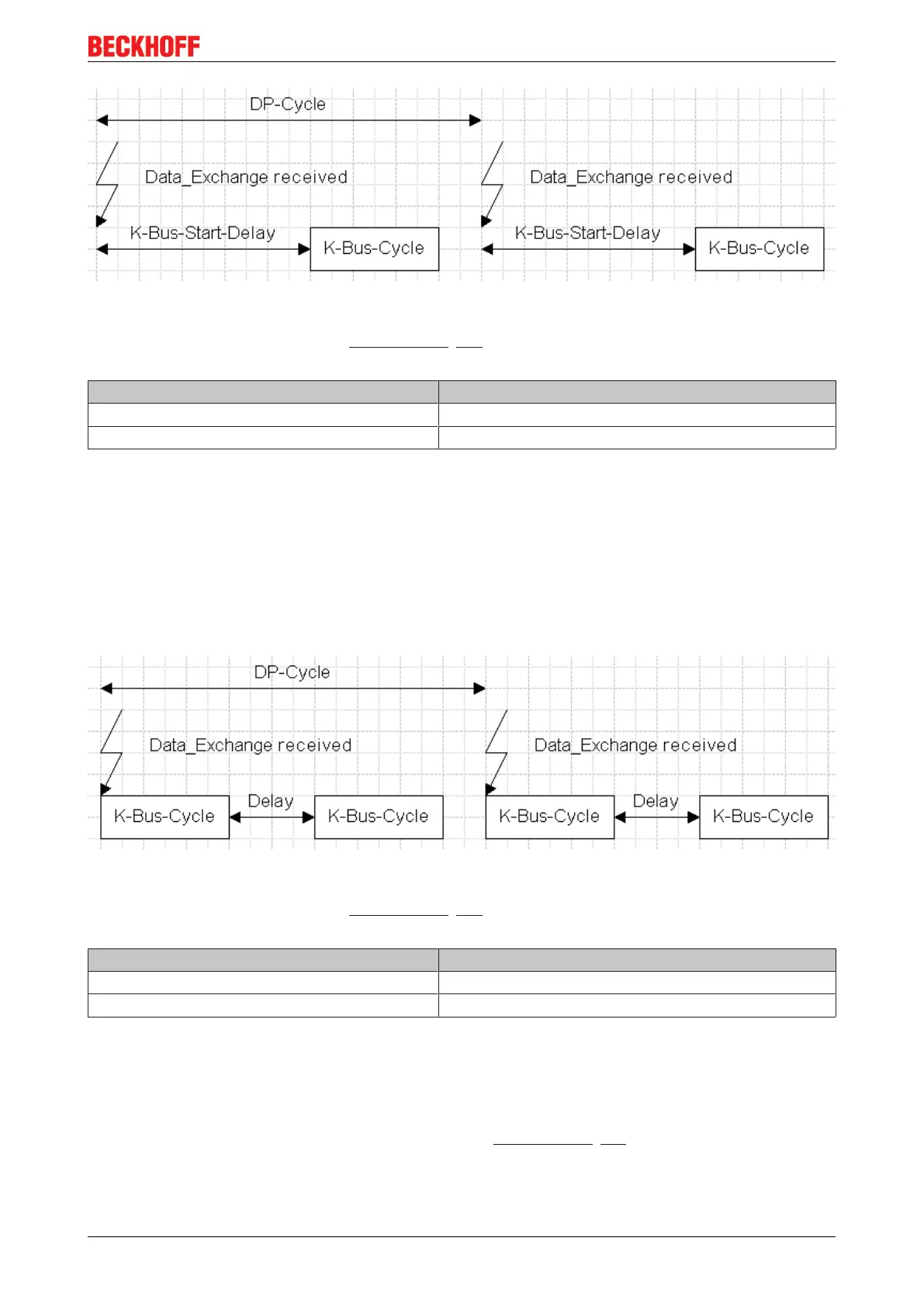

Explains the configurable settings within the Bus Coupler's UserPrmData.

Introduces the overall configuration process for Bus Couplers.

Explains how CfgData is generated from DP configuration tools.

Details how to add DP modules for Bus Coupler functions.

Guides on adding complex terminals in the DP configuration tool.

Explains the configuration process for digital terminals.

Details the configuration process when using a Siemens S7 controller.

Provides an overview of DP diagnostic data and its interpretation.

Explains the structure and content of DP standard and device-specific diagnostic data.

Lists and explains potential errors occurring during the DP start-up phase.

Details errors related to checking the CfgData integrity and content.