111

Volt~ge

measurement

1.

Checking

the

control voltage

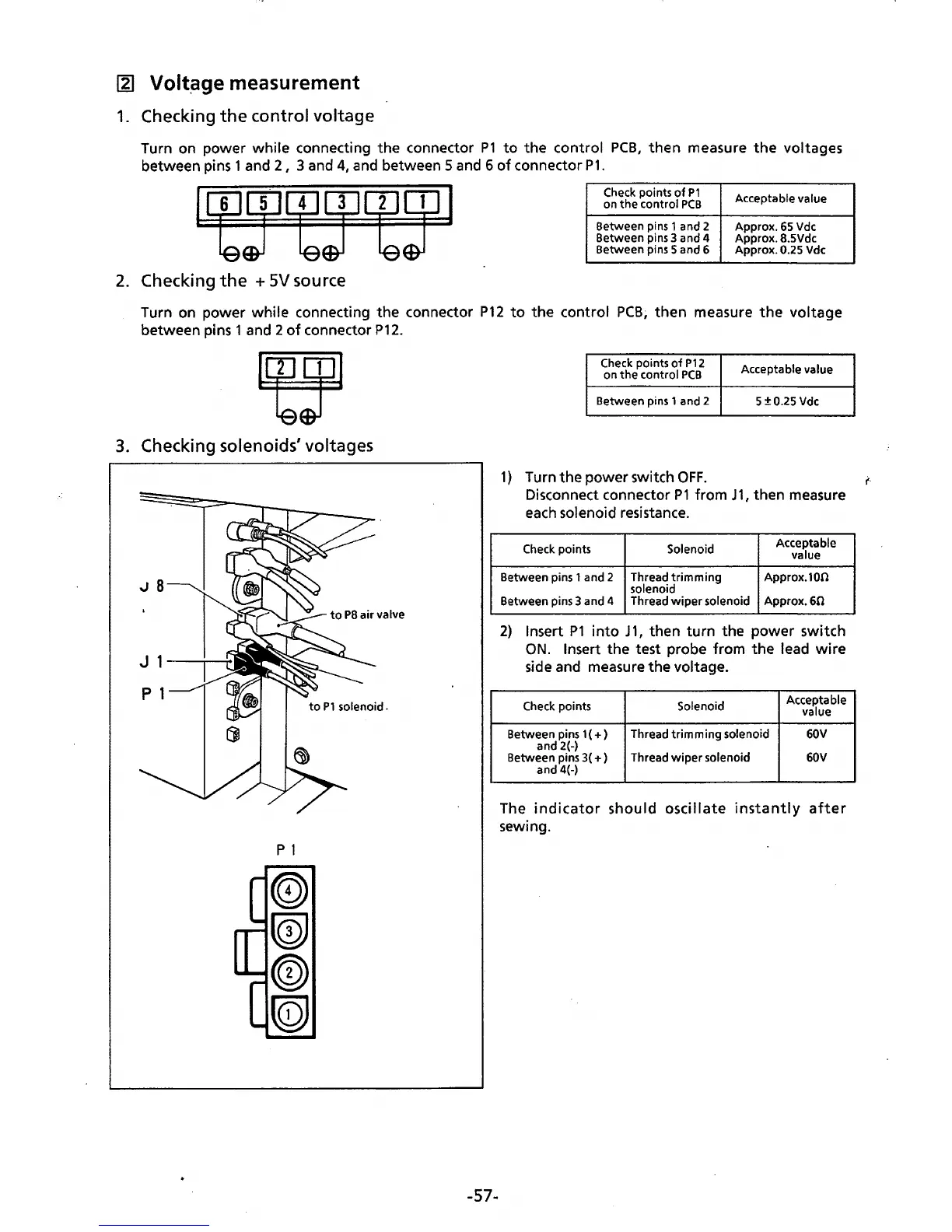

Turn on power while connecting the connector

P1

to

the control

PCB,

then measure

the

voltages

between pins 1 and

2,

3 and

4,

and

between 5 and 6

of

connector

P1.

Check points

of

P1

Acceptable value

on

the

control

PCB

Between pins 1 and 2

Approx.

65

Vdc

Between pins 3 and 4

Approx. 8.5Vdc

Between pins 5 and 6

Approx.

0.25 Vdc

2.

Checking

the

+

SV

source

Turn on power while connecting the connector

P12

to

the control

PCB~

then

measure

the

voltage

between pins 1 and 2

of

connector

P12.

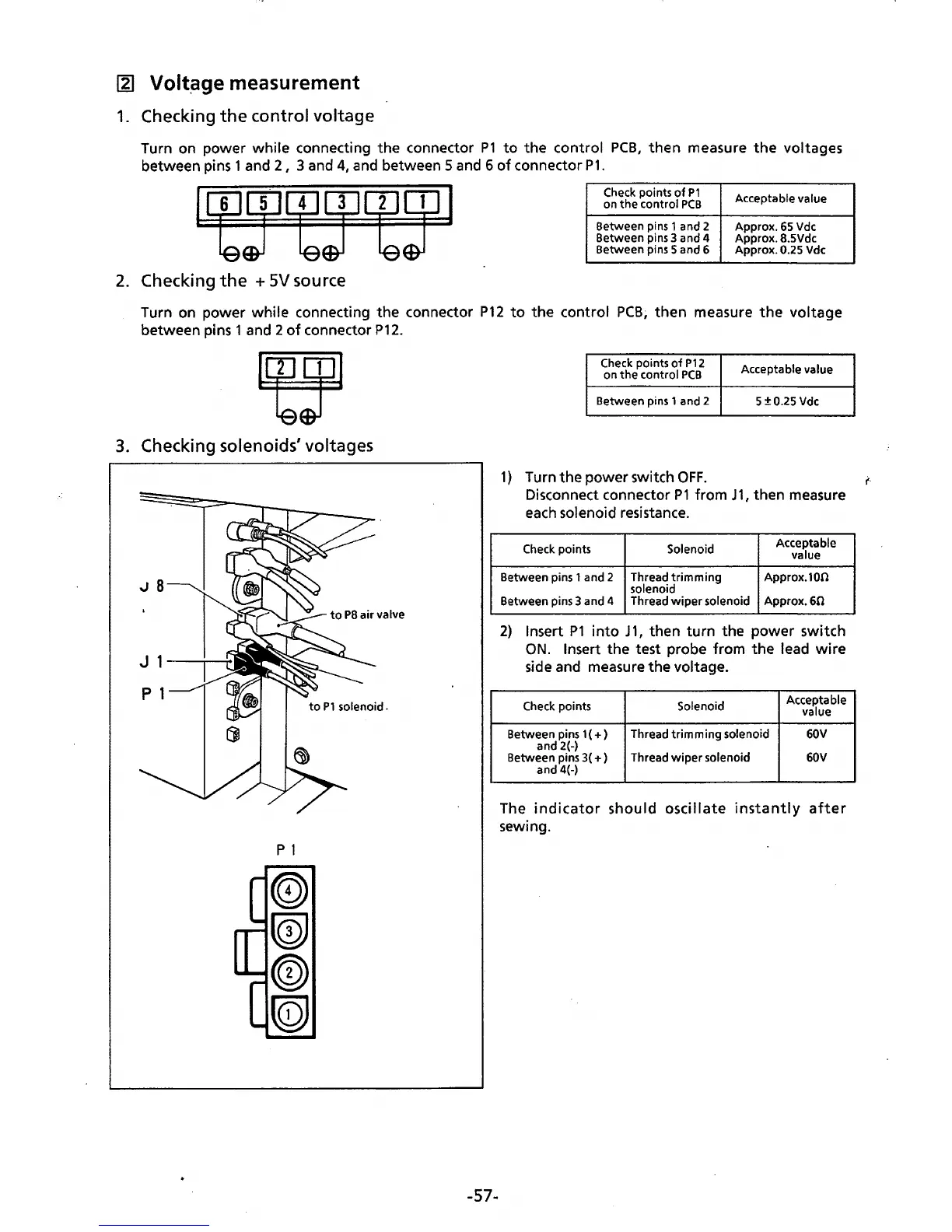

3.

Checking solenoids' voltages

p 1

-57-

Check points

of

P12

on

the

control

PCB

Acceptable value

Between pins 1 and 2

5

±0.25

Vdc

1)

Turn the power switch

OFF.

i'·

Disconnect connector

P1

from

J1,

then measure

each

solenoid resistance.

Check points

Solenoid

Acceptable

value

Between pins 1 and 2 Thread

trimming

solenoid

Approx.100

Between pins 3 and 4 Thread

wiper

solenoid

Approx.60

2)

Insert

P1

into

J

1,

then

turn

the power switch

ON.

Insert the test probe from

the

lead

wire

side and measure the voltage.

Check points Solenoid

Acceptable

value

Between pins 1 (

+)

and 2(-)

Thread

trimming

solenoid 60V

Between pins 3(

+)

Thread

wiper

solenoid 60V

and 4(-)

The

indicator

should

oscillate

instantly

after

sewing.

Loading...

Loading...