Chapter 2

2-28

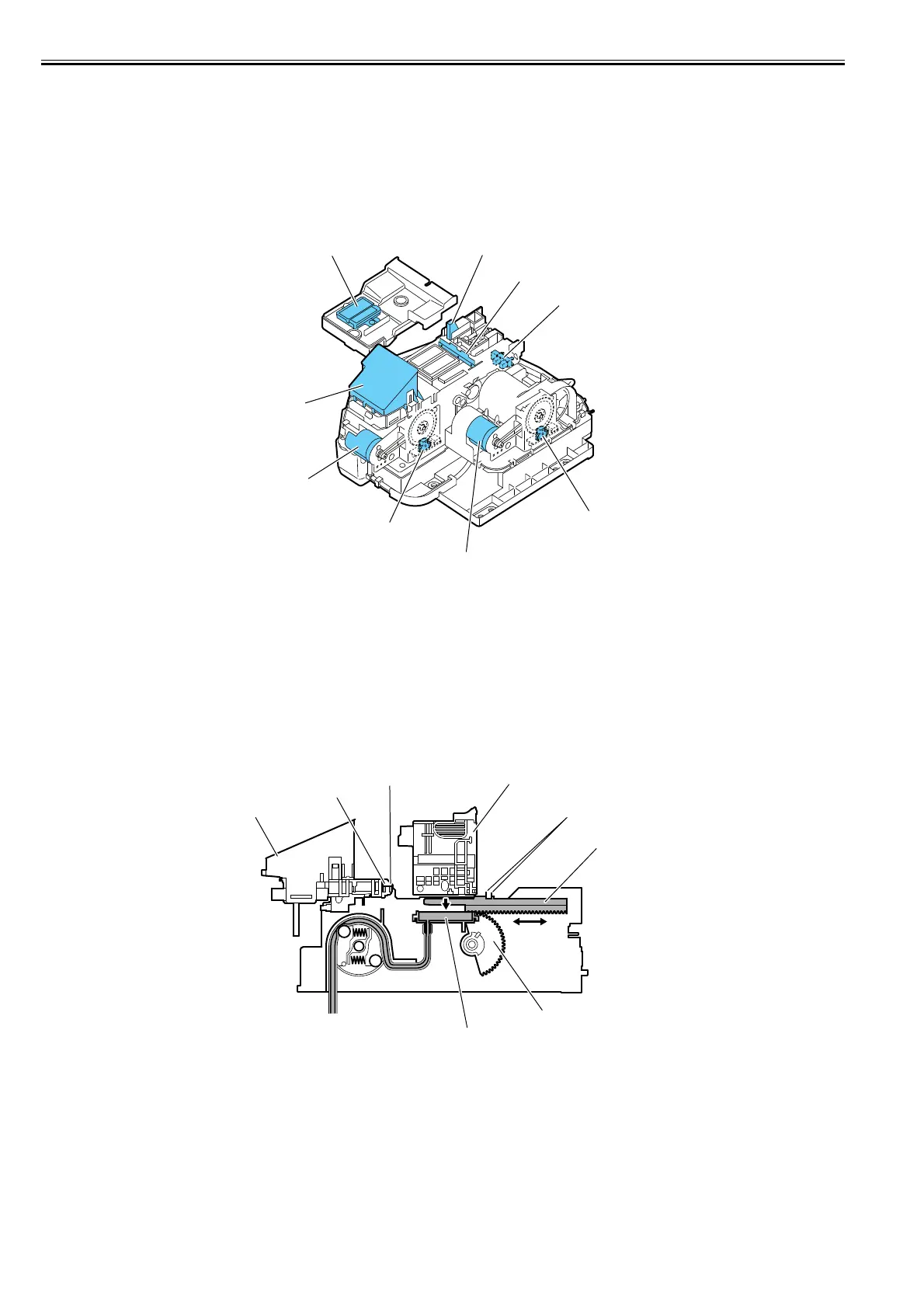

2.3.2.5.2 Structure of Purge Unit

0020-5494

a) Caps

The caps cap the nozzle assembly in the left printhead during capping and cleaning. The part of the caps that comes into contact with the face plate of the nozzle

assembly is made of rubber. Two caps are in position to meet each of the printheads mounted on the carriage (six trains of nozzles).

The caps are activated to protect the nozzle assembly on capping. When the carriage moves to the home position, the caps are elevated by the cap cam that is driven

by the capping motor, capping the nozzle assembly to protect it.

These caps cap the nozzle assembly to suck inks from the printhead by means of the suction pump.

b) HP maintenace jet tray

An HP maintenace jet tray is located at the home position of the platen, transporting idle discharges of the pigment and dye inks through their respective tubes to

the pump unit in the purge unit.

F-2-15

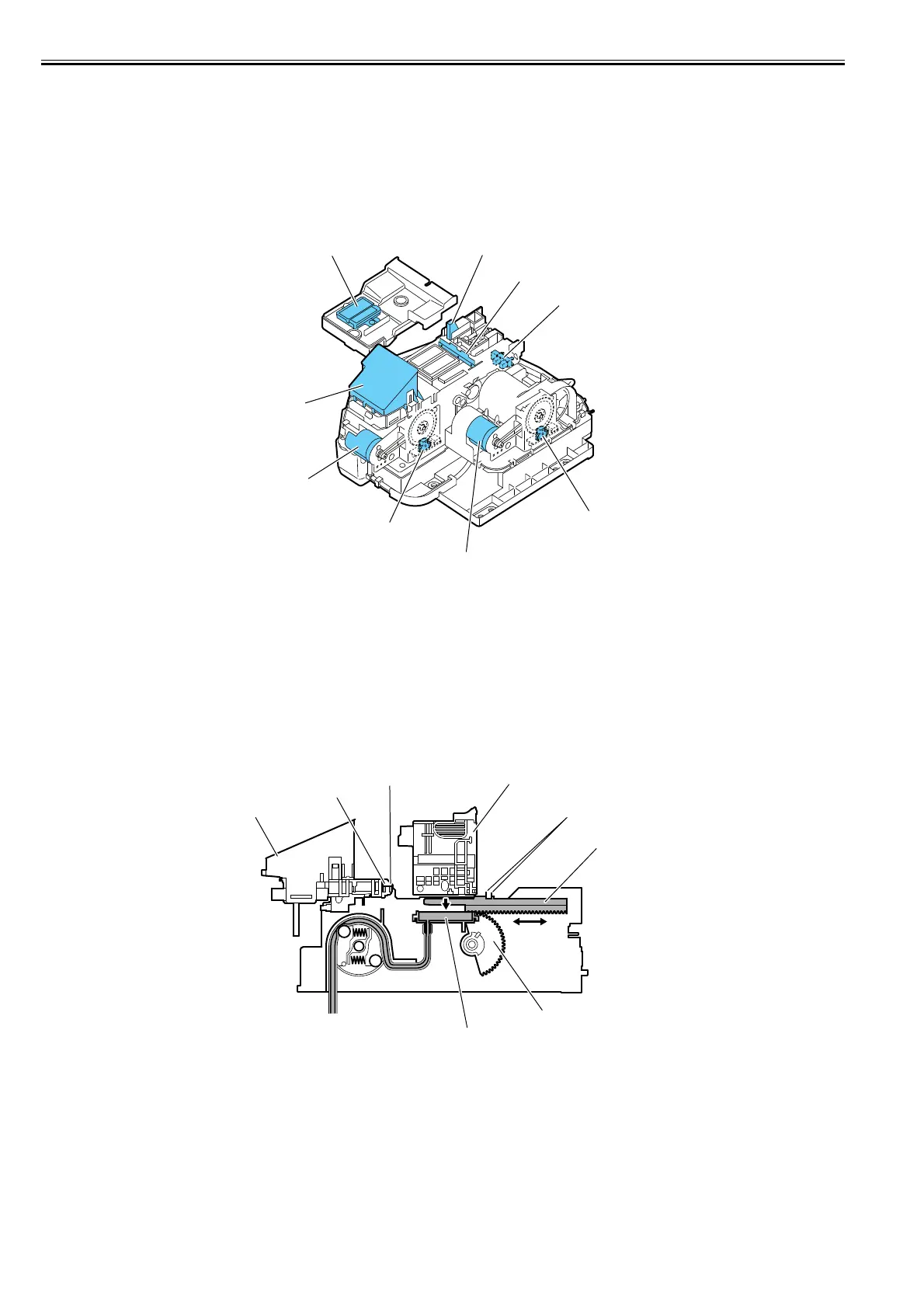

c) Wipers

The wipers are driven by the purge motor to wipe the six trains of nozzles in the nozzle assembly in the printhead simultaneously.

A pair of wiper blades are in position to ensure wiping performance. The wiping operation operates on a slide wiping basis, sliding the wiper blades via wiper cams

through the normal rotation of the purge motor.

Wiping is executed by the wiper blades moving at a constant speed to the front of the printer after the end of a print or suction operation.

A wiper blade set perpendicularly to the head wipes the entire face of the printhead, followed by a narrower blade wiping the nozzle assembly.

The wiper blades are cleaned before they are replaced at the wiping position after wiping to preserve wiping performance.

Wiper blade cleaning is carried out by scraping off the inks that have been wiped off from the head with an ink scraper linked to the maintenance cartridge, then

wiping the blades with a blade cleaner.

Wet wiping is carried out for added wiping removal performance, whereby the wiper blades are moistened with glycerin as they are pressed against an absorber

impregnated with glycerin. The quantity of glycerin used is managed by counting the number of times the wiper blades have been pressed against the absorber.

When this count reaches to the specified values, either a replacement warning (continued print available) or replacement required indication (service call error) is

issued.

F-2-16

d) Pump

The pump is a tube pump that pressurizes the ink tubes with rotating rollers to produce a negative pressure for sucking inks. Each individual tube is sequentially

pressurized by two rotating rollers to control the rate of ink suction by a wide margin.

The rate of rotation of the rotating pumps is controlled by driving the purge motor or the HP maintenance jet pump motor as the timing at which the rotating pumps

Wiper unit

Carriage lock pin

Purge motor

HP maintenance jet pump motor

HP maintenance jet

pump encoder sensor

HP maintenance jet tray

Glycerin tank

Pump encoder sensor

Pump cam sensor

Cap

Ink scraper

Glycerin

absorber

Printhead

Wiper blades

Blade holder

Glycerin tank

Wiper cam

Loading...

Loading...