16

Another effect which has been noted, especially in multi-

ple compressor systems, is the increased probability of

blown valve plate gaskets when excessive oil is in the

system. When the system is grossly overcharged (several

gallons too much), the oil levels in the compressor

sumps will only rise 1/2 to 3/4 level in the sightglass of

06E compressors. The remainder of the oil will be kept

in circulation or will accumulate somewhere in the sys-

tem. A likely point is in the suction manifold (depending

on the method of returning oil), and in the compressor

motor compartment. This is especially troublesome in an

idle compressor in a multiple compressor system that

has an opportunity to accumulate oil in the motor com-

partment; but excessive oil in the motor compartment at

start-up will not alone fail gaskets. Some liquid refriger-

ant must also be present which will bring enough oil

with it into the cylinders on a start-up to cause gasket

failures. These circumstances have apparently occurred

in a number of installations, and their relationship to

gasket failures has been well confirmed by test.

To check for excessive system oil charges in 06E com-

pressors, it is recommended that the oil levels of the

compressors in the system be brought down to approxi-

mately 1/4 of the sightglass. If the system is overcharged,

the oil levels will rise to a 1/2 sightglass level within a

short time (usually within an hour). Continue removing

oil until the oil level does not rise after removal. It is

also recommended that the oil levels be kept at this 1/4

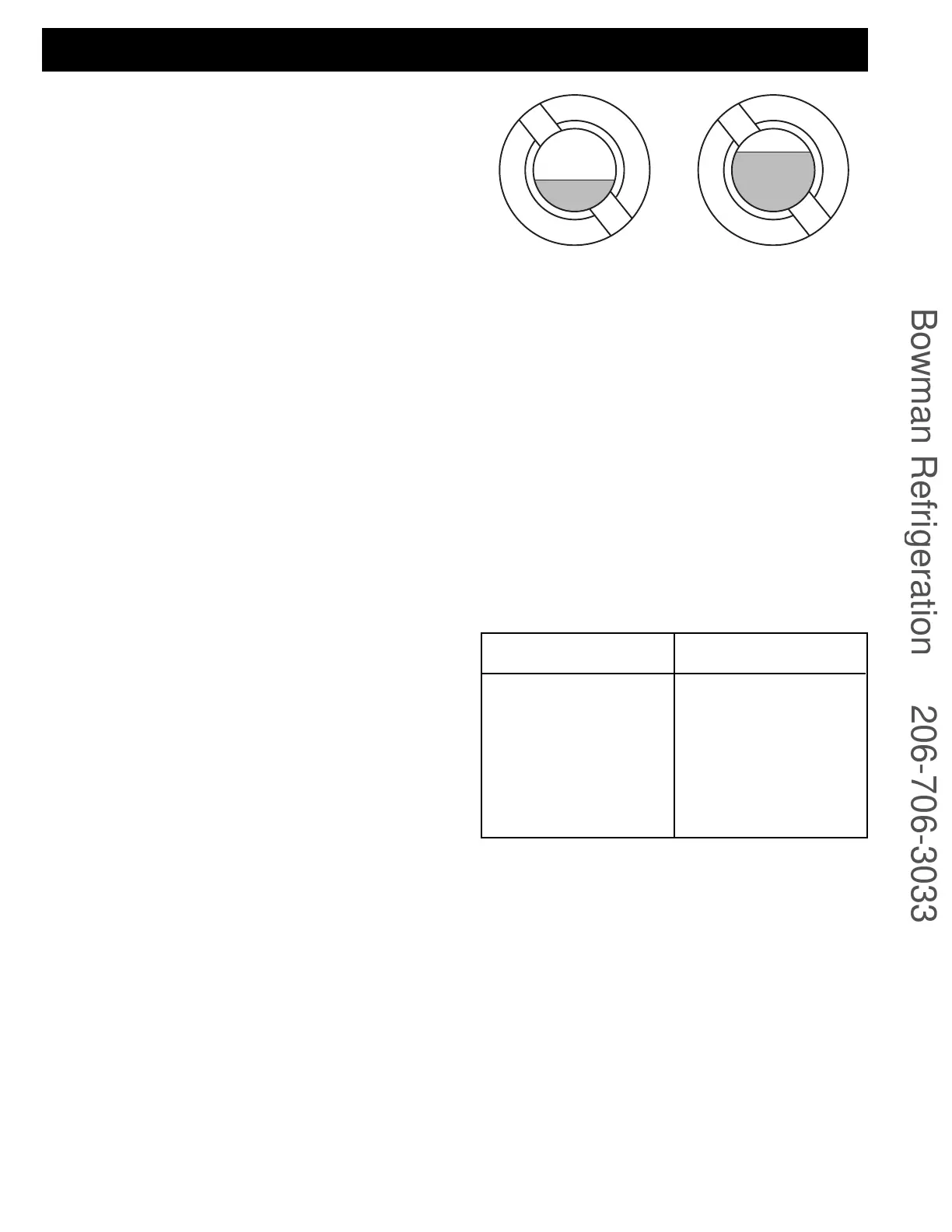

level, or between the levels shown in Figure 8. This is

especially true if any compressors have experienced any

repeated gasket failures. To summarize the advantages of

keeping the oil at this level:

1. It ensure that excessive oil is not being lodged in the sys-

tem. This will eliminate gasket, valve, and running gear

failures.

2. The compressor, oil, and motor run cooler, approxi-

mately 20°F (11°C) or more in many cases.

As noted above, the oil level control in 06D compressors

is less critical than 06E models. Motor barrel equaliza-

tion is not required and oil level in the compressor

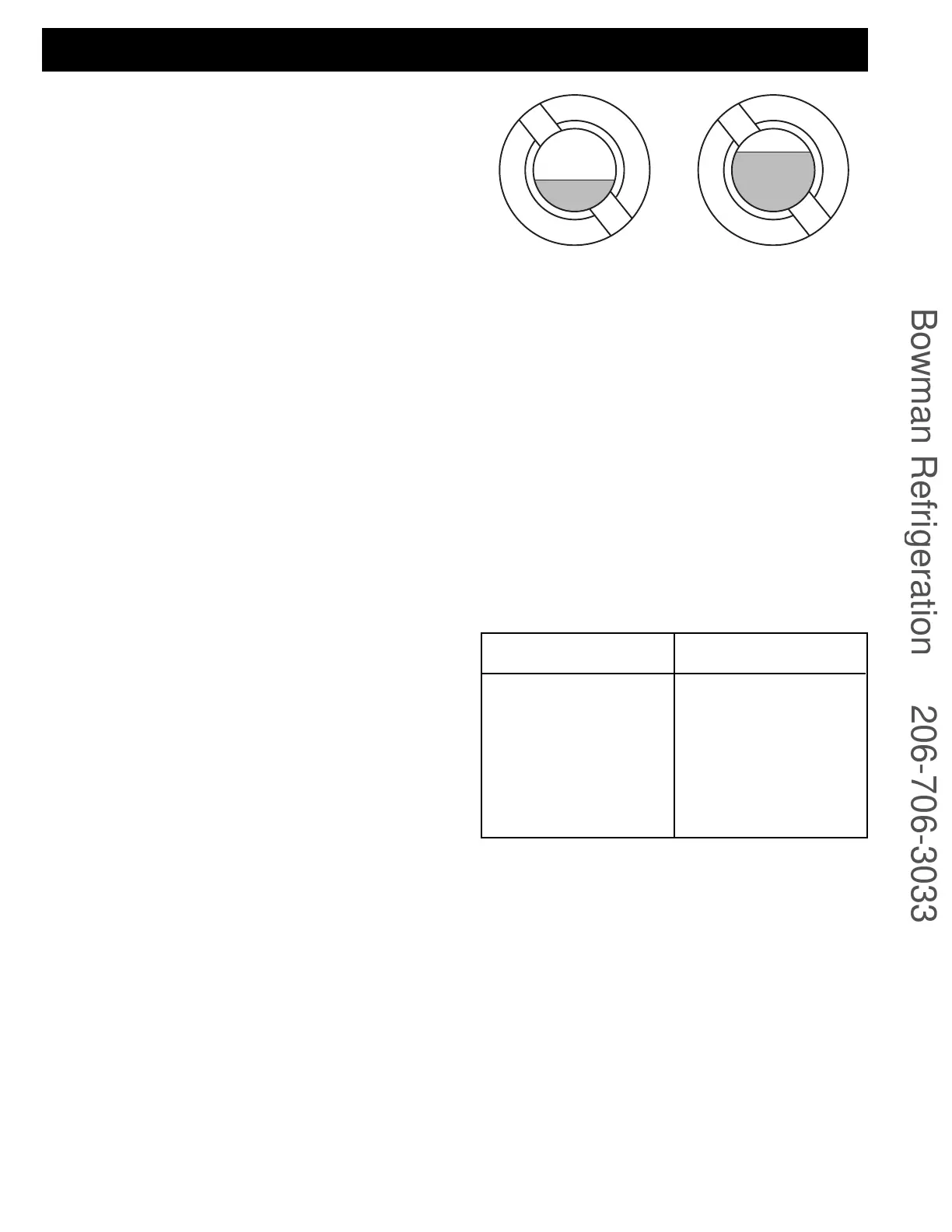

sightglass should be controlled between 1/4 to 3/4 of the

sightglass (See Figure 9). If the oil level in the sightglass

is less than one-quarter (1/4) up from the bottom of the

glass, this indicated a low oil level. If the oil level is up

more than three-quarters (3/4) from the bottom, this

indicates a high oil level. Again, the oil level should be

checked immediately after the compressor is shut down.

2.2 The Oil Pump

The 06D and 06E oil pump is a positive displacement

vane type that produces high volume oil flow at a low oil

pressure. The compressor utilizes an internal pressure

regulator valve to maintain oil pressure at a constant 12

to 36 psi (.83 to 2.5 bar) above suction pressure.

2.3 Recommended Oils

When additional oil or a complete oil change is

required, use only the listed Carlyle approved oils.

For CFC and HCFC refrigerants use:

Loading...

Loading...