21

3.8 Pressure Differential (∆P) Required to Load

Compressor

A minimum ∆P between the discharge and suction pres-

sure is required to compress the unloader valve spring

to load up the cylinder bank. While this differential pres-

sure is low, it should be evaluated for certain low head

pressure applications such as R-12, R-134a, air condi-

tioning applications or the low stage of booster applica-

tions. The discharge pressure must be higher than the

suction pressure in Table 4 (Page 20) for the unloader

assembly to load up.

Suction cut-off unloading is an option for all four and six

cylinder Carlyle 06D/E compressors. The capacity con-

trol operation and application requirements are found in

the System Design section (Section 1.0) of this manual

and should be carefully reviewed.

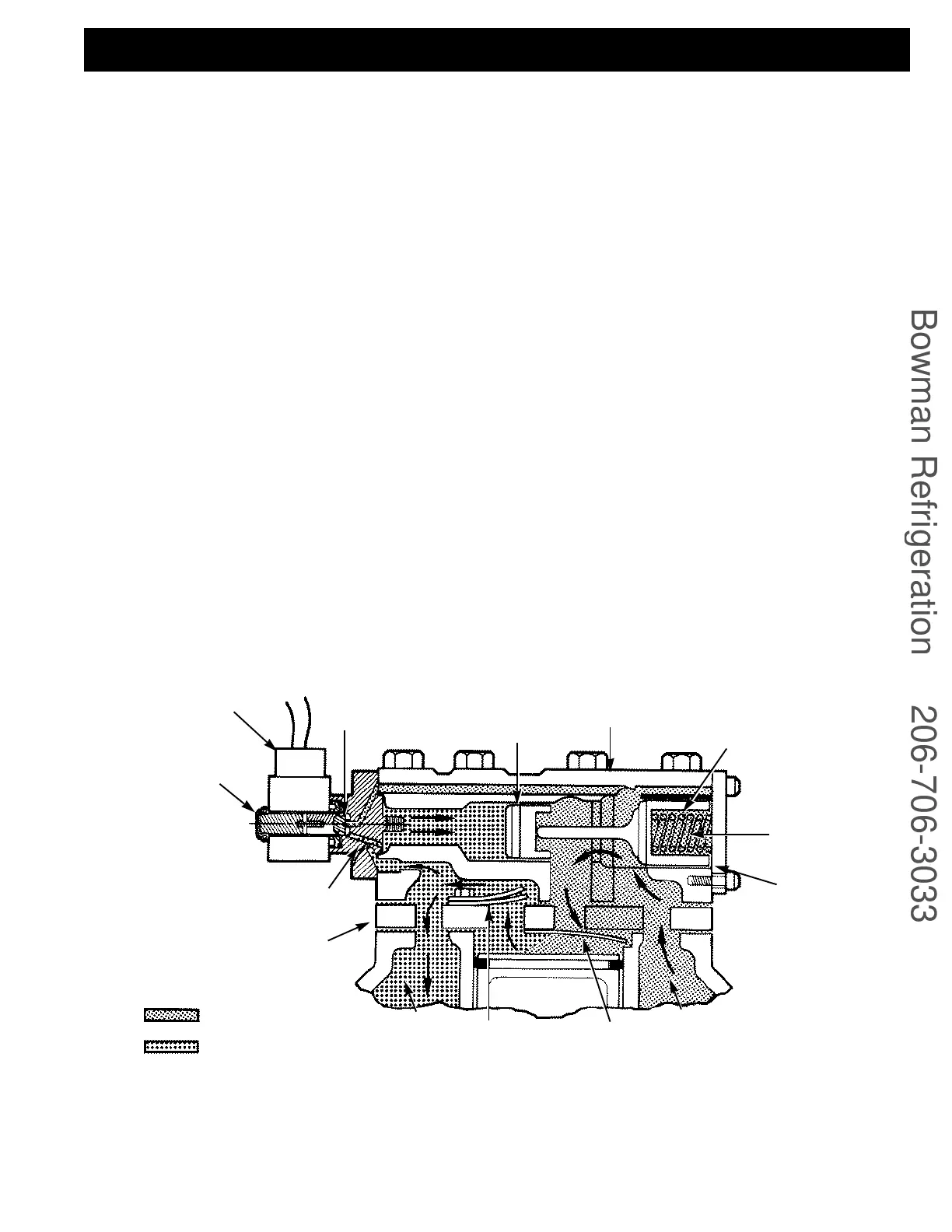

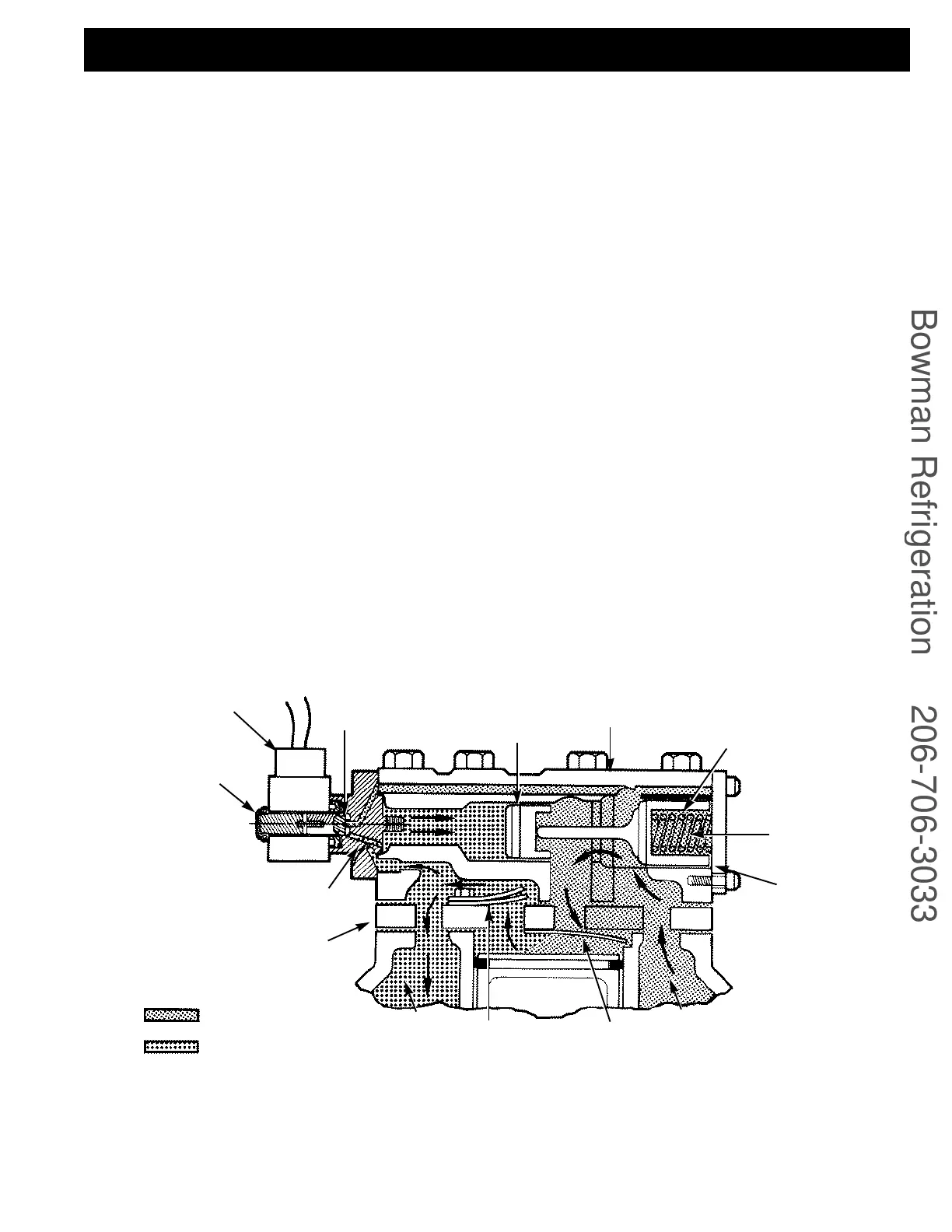

3.9 Electric Solenoid Capacity Control Operation

The electrically operated control valve is actuated by

remote signal to the electric solenoid coil. Each valve

controls 2 cylinders (1 bank). No manual adjustments to

the electric unloader valve are necessary. When the sole-

noid is “de-energized”, the passageways in the valve are

aligned for “loaded” conditions. When the solenoid is

“energized”, the valve passageways are aligned for

unloading.

This capacity control valve is controlled by an electric

solenoid. When the solenoid is de-energized, the valve

loads the cylinder bank (2 cylinders) as shown in

Figure 12.

When full capacity is desired, an external controller de-

energizes the solenoid coil, allowing the discharge pres-

sure to build-up behind the unloader piston assembly.

This will compress the unloader valve spring, opening

the unloader suction port. Suction gas can now be

drawn into the cylinders, running the bank fully loaded.

Loading...

Loading...