22

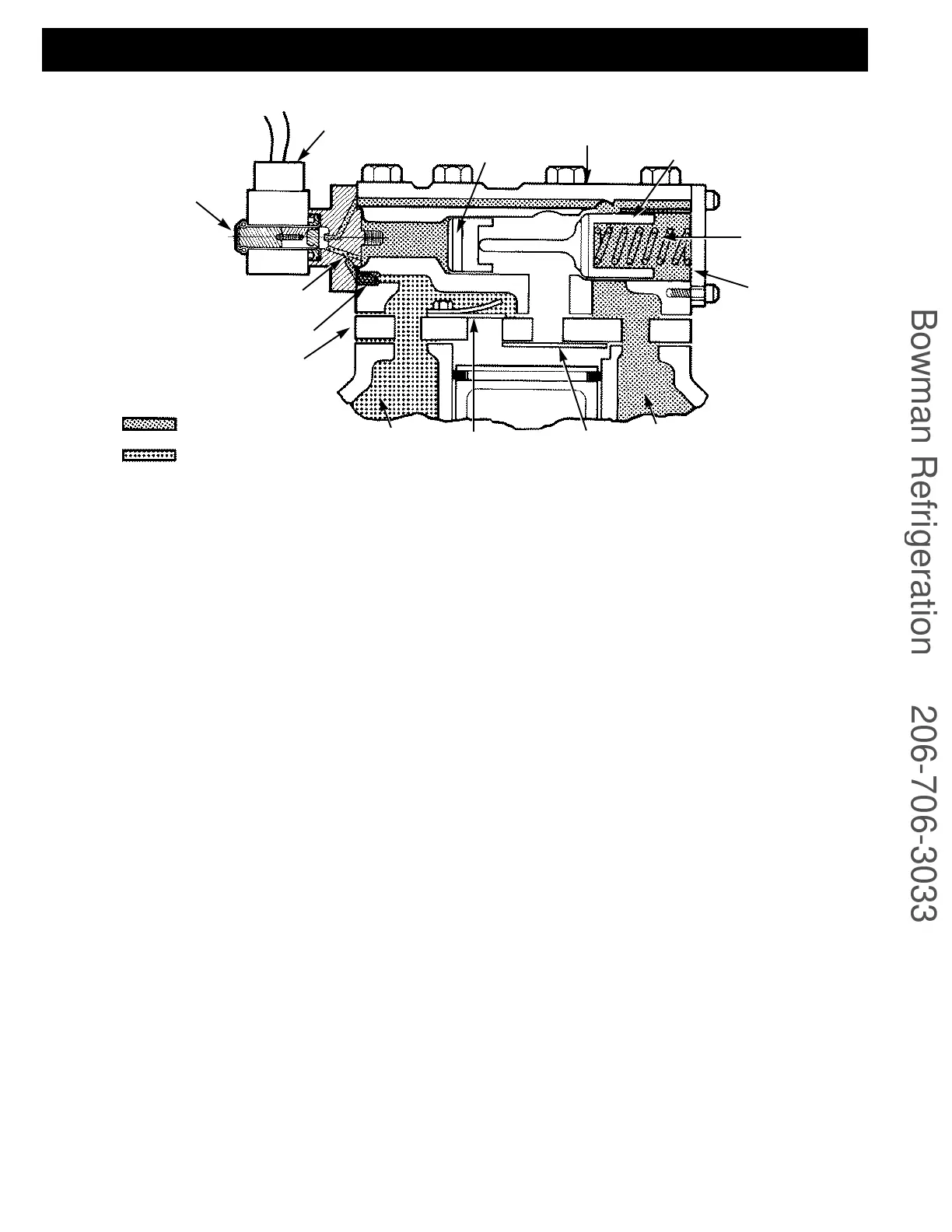

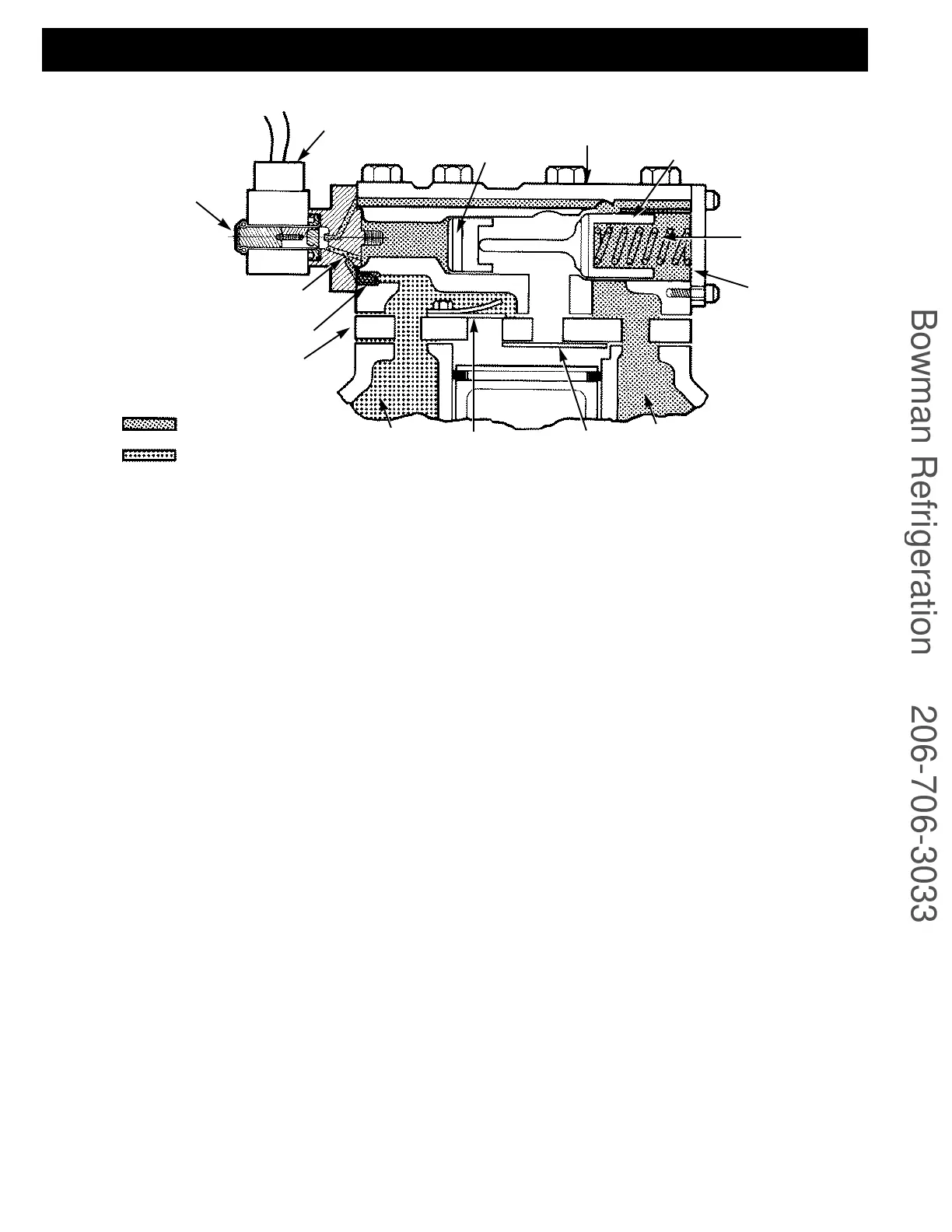

As reduced capacity is desired an external controller

energizes the solenoid coil. This opens the capacity con-

trol valve port, allowing the discharge gas behind the

unloader piston assembly to vent back to the suction

side as shown in Figure 13. The unloader valve spring at

this point can move the unloader valve body to the left,

blocking the unloader suction port. The cylinder bank is

now isolated from the compressor suction manifold,

unloading these two cylinders. No refrigerant is allowed

into the cylinders and no compression takes place.

3.10 Suction Pressure Capacity Control

Operation

Pressure-operated control valve is controlled by suction

pressure and actuated by discharge pressure. Each valve

controls 2 cylinders (1 bank). On start-up, controlled

cylinders do not load up until the differential between

suction and discharge pressures is approximately 25 psi

(1.7 bar) for 06D compressors and 35 psi (2.4 bar) for

06E models. See Table 4, page 20.

When suction pressure rises high enough to overcome

set point spring, the diaphragm snaps to the left and

relieves pressure against the poppet valve. The drive

spring moves the poppet valve to the left and it seats in

the closed position.

With the poppet valve closed, discharge gas is directed

into the unloader piston chamber and pressure builds

up against the piston. When pressure against the

unloader piston is high enough to overcome the

unloader valve spring, the piston moved the valve to the

right, opening the suction port. Suction gas can now be

drawn into the cylinders and the bank is running fully

loaded (as shown in Figure 12A).

As suction pressure drops below the set point, the con-

trol spring expands, snapping the diaphragm to the

right. This forces the poppet valve open and allows gas

from the discharge manifold to vent through the base

control valve to the suction side. Loss of full discharge

pressure against the unloaded piston allows the unloader

valve spring to move the valve left to the closed position.

The suction port is blocked, isolating the cylinder bank

from the suction manifold. The cylinder bank is now

unloaded (as shown in Figure 13A).

Loading...

Loading...