5.0 Compressor Features and Accessories

33

5.1 Safety Relief Valves

All 06E compressors are equipped with built-in safety

relief valves that are factory set to relieve from the dis-

charge to the suction side of the compressor at a pres-

sure differential of 400 psi (27 bar). On the 4-cylinder

06E compressor, the relief valve is located below the dis-

charge service valve in the compressor crankcase. On

the 6-cylinder 06E compressors, it is located in the cen-

ter bank (below the valve plate) of the crankcase. The

06D compressors do not have a relief valve, since they

are only required in compressors greater than 50 cfm

(1.42 m3/min). During factory or field leak testing dis-

charge side pressures should not exceed 350 psi to

avoid inadvertently causing the relief valve to open. If

this opens the relief valve may require replacement.

System problems that result in the compressor operating

at elevated head pressures (for example – cycling on the

high pressure switch) may also cause the relief valve to

subsequently open at lower operating pressures and thus

require replacement.

5.2 Suction Strainers

Each 06D and 06E compressor is equipped with a suc-

tion strainer located in the suction manifold of the motor

end bell (except on 2-cylinder models where it is locat-

ed on the compressor side of the suction service valve.

5.3 Oil Safety Switch

Carlyle has approved the following oil safety switches for

use with all 06D and 06E compressors:

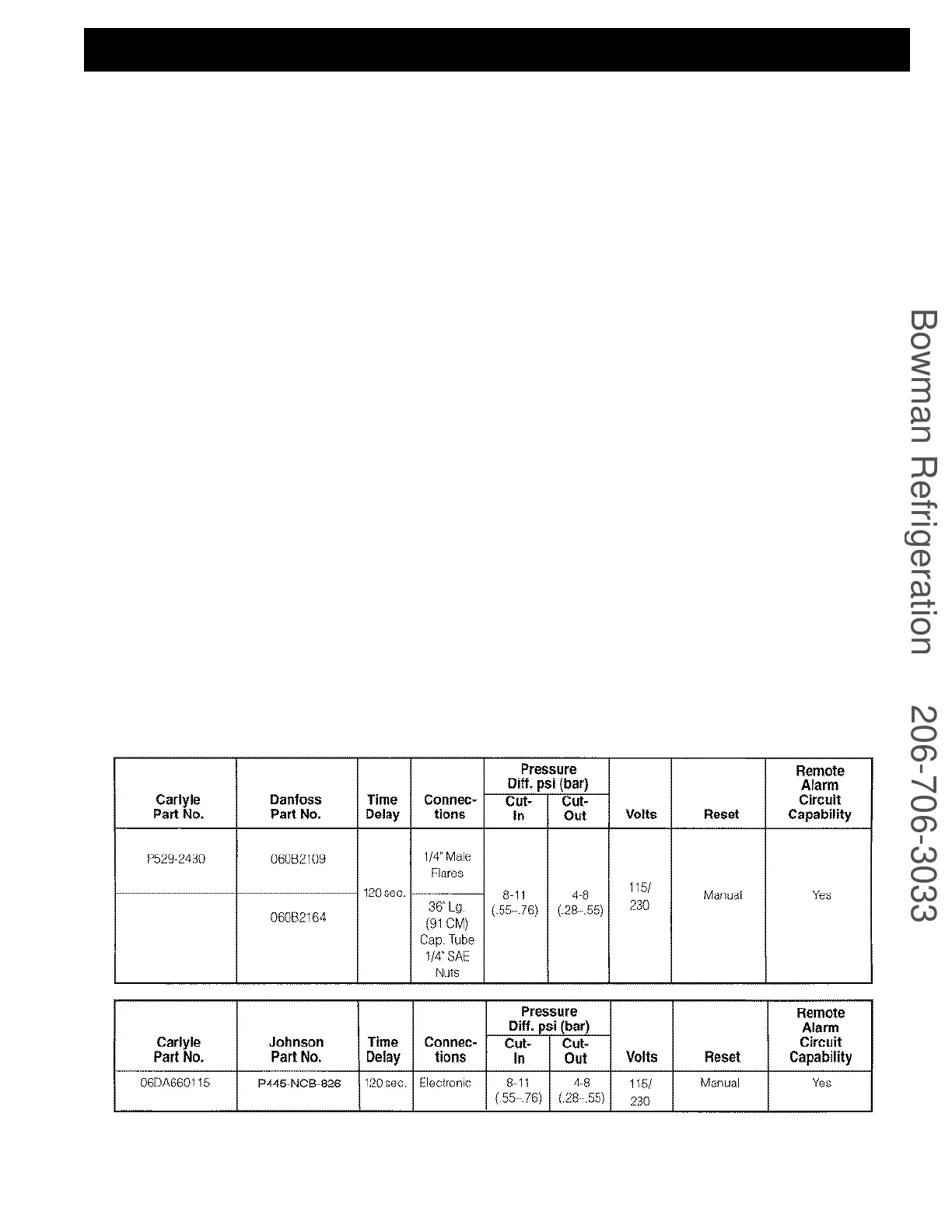

1. Danfoss: (see Table 10 below)

2. Penn: P45-NCA-82(STD) or 45-NCB-14 with alarm

circuit.

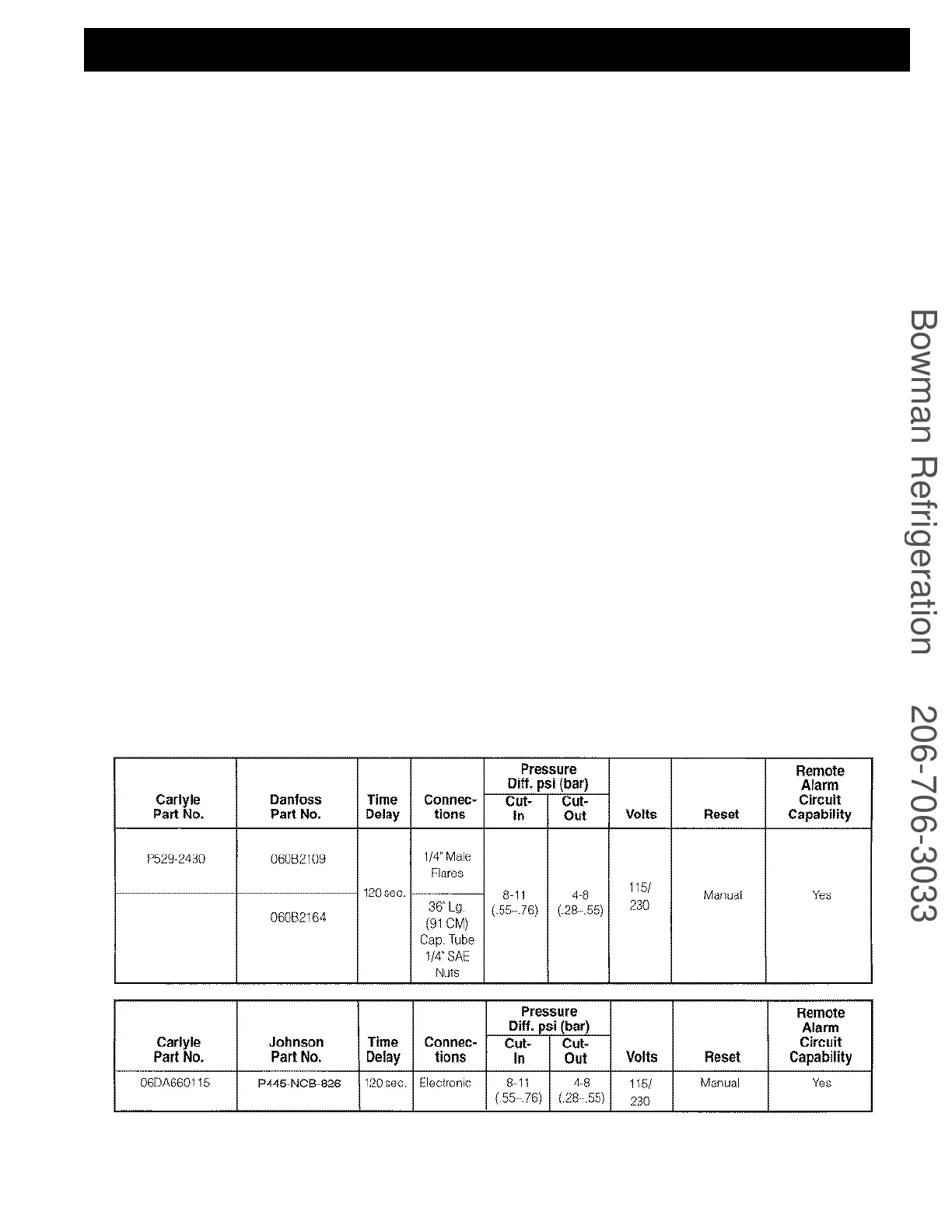

3. Johnson Controls: P445 (see Table 10 below)

Table 10 below shows the specifications for the Carlyle

approved Danfoss Type series oil safety switches that are

currently stocked by Carlyle.

The oil safety switch is designed to protect the compres-

sor against loss of lubrication. The switch will close the

control circuit at start-up (within the 120 second time

delay), when the compressor operating oil pressure is at

a maximum of 11 psi (.75 bar) above suction pressure.

The switch will open the control circuit and shut the

compressor off when the oil pressure drops to a mini-

mum of 4 psi (.27 bar) above suction pressure and

remains for the allotted 120 seconds. Carlyle’s new high-

er flow oil pump has been found to improve lubrication

during abuse conditions. As a result, for compressors

built with the new higher flow oil pump (starting

S/N1094J...), the allowable time delay has been

increased from 45 to 120 seconds.

Loading...

Loading...