19

30AW

Installation

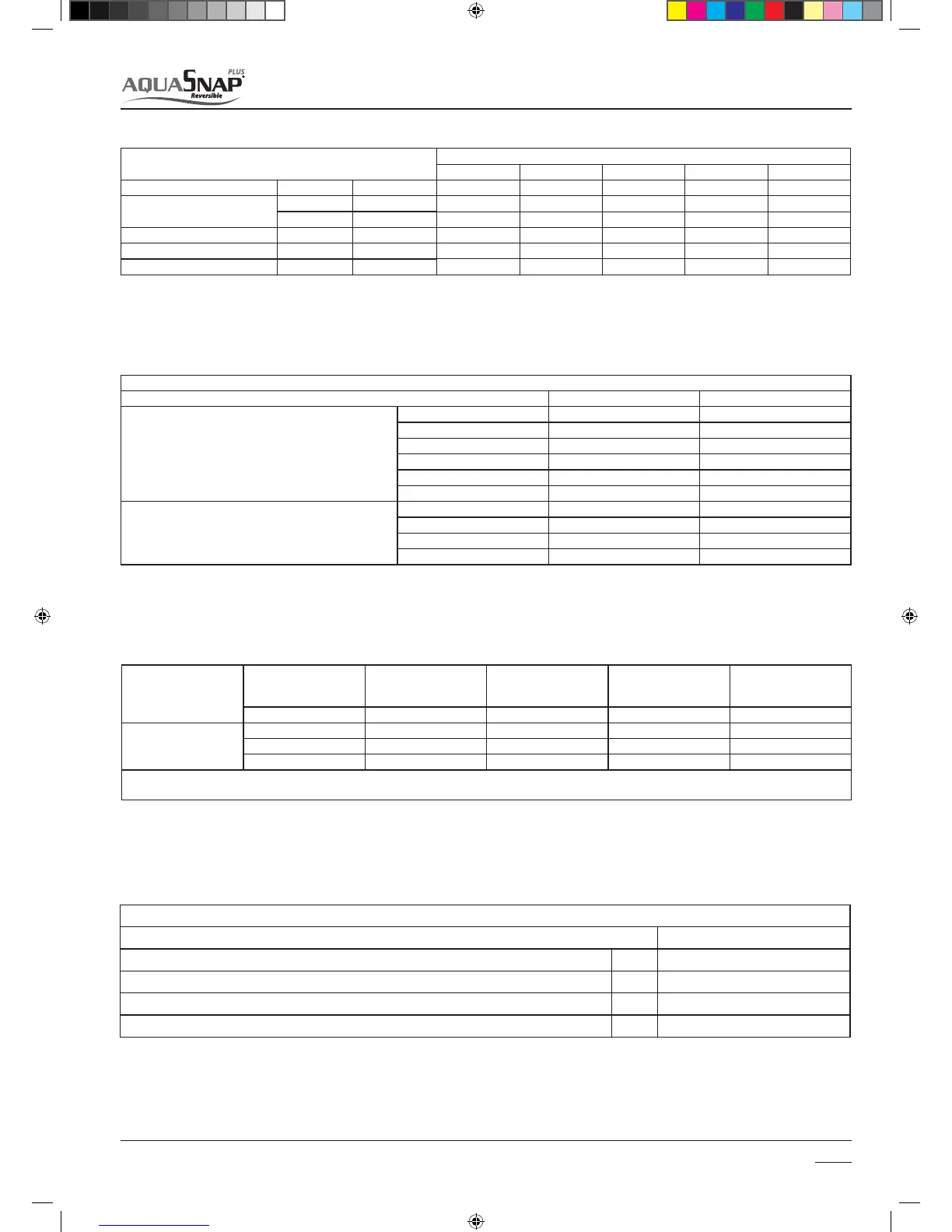

3

% Inhibited

Ethylene

Glycol

10% 20% 30% 40%

Freezing temperature (*) -4 °C -9 °C -15 °C -23 °C

Correction

Factors

Capacity 0,996 0,991 0,983 0,974

Absorbed power 0,990 0,978 0,964 1,008

Loss of head 1,003 1,010 1,020 1,033

(*) Note: Temperature values are indicative.

Always refer to the temperatures indicated for the specic product used

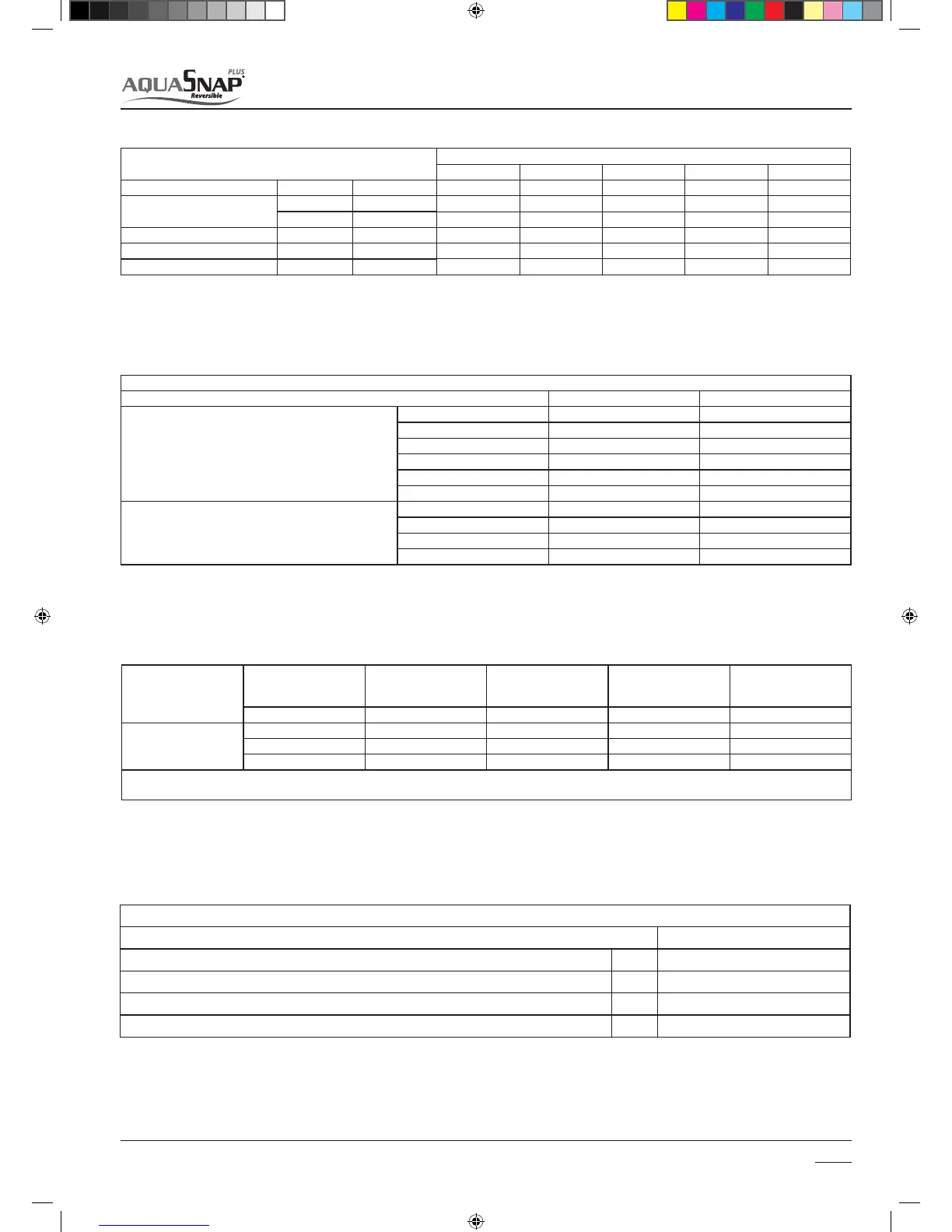

Pipe water content

Internal Diameter Outer diameter Liters / meter

copper

12 mm 14 mm 0,11 l/m

14 mm 16 mm 0,15 l/m

16 mm 18 mm 0,20 l/m

20 mm 22 mm 0,31 l/m

25 mm 28 mm 0,49 l/m

32 mm 35 mm 0,80 l/m

steel

"12.7 mm (1/2'')" 3/8'' Gas 0,13 l/m

"16.3 mm (5/8'')" 1/2'' Gas 0,21 l/m

"21.7 mm (7/8'')" 3/4'' Gas 0,37 l/m

"27.4 mm (11/16'')" 1' G as 0,59 l/m

Unit

30 AWH

004 006 008 012 015

Nominal water ow

Std l/s 0,20 0,28 0,33 0,58 0,69

Water loop content for

30AWH___H units

Min l 14 21 28 42 49

Max l 65 65 65 95 95

Max water loop pressure

Max kPa 300 300 300 300 300

Filling water pressure

Min kPa 120 120 120 120 120

Max elevation 30AW upper

Max m 20 20 20 20 20

TABLE TO USE FOR CALCULATING THE WATER CONTENT IN THE SYSTEM

Installed Unit .............

Unit content (*) l .............

Pipe content (**) l .............

Uses (fan-coil, panels, radiators, etc.) (***) l .............

Total content (****) l .............

(*) Consult the technical data table

(**) Consult the pipe water content table

(***) Consult the manual for the installed uses

(****) The water content of the system must be between the minimum and maximum values for the units with hydronic kit and greater than the minimum

value for units without hydronic kit. The minimum value is necessary to provide optimal comfort.

For units without hydronic kit, add a suitable expansion vessel to the water content of the system.

SM_30AW.indd 19 14-03-2011 14:41:27

Loading...

Loading...